The Warner clutch brake module UM50-1020-90VDC is a critical component in various industrial machinery, often found in applications requiring precise motion control. When this module malfunctions, it can lead to significant downtime and productivity loss. This article provides a comprehensive guide to troubleshooting and resolving common issues with the Warner UM50-1020-90VDC clutch brake module, helping you get your equipment back up and running quickly. We’ll cover everything from basic checks to more advanced diagnostic techniques, enabling you to identify and address the root cause of the problem.

Understanding the Warner UM50-1020-90VDC

The UM50-1020-90VDC module is designed to control the engagement and disengagement of a clutch and brake assembly. It receives signals from a control system and uses them to energize or de-energize the clutch and brake coils. Understanding the module’s functionality is crucial for effective troubleshooting. The module operates on 90VDC and is specifically designed for the Warner clutch and brake series. Its compact design and robust construction make it suitable for demanding industrial environments.

The module plays a critical role in ensuring smooth and controlled operation of machinery. A malfunctioning module can lead to jerky movements, inaccurate positioning, and even complete system failure.

Common Issues and Troubleshooting Steps

Several factors can contribute to problems with the Warner clutch brake module UM50-1020-90VDC. These range from simple wiring issues to more complex internal component failures. Here’s a systematic approach to troubleshooting:

Power Supply Verification

First, ensure the module is receiving the correct voltage. Use a multimeter to check the input power lines. Incorrect voltage can damage the module and prevent it from functioning properly.

Wiring and Connections

Inspect all wiring connections for looseness, corrosion, or damage. A loose or corroded connection can interrupt the flow of current and prevent the module from operating.

Input Signals

Verify that the control signals are reaching the module correctly. Use an oscilloscope or a logic analyzer to monitor the input signals. Incorrect or missing signals can indicate a problem with the control system.

Coil Resistance

Measure the resistance of the clutch and brake coils. Values outside the specified range can indicate a faulty coil.

Internal Component Inspection

If the above checks don’t reveal the issue, the module itself may be faulty. This could involve damaged internal components such as the rectifier or control circuitry.

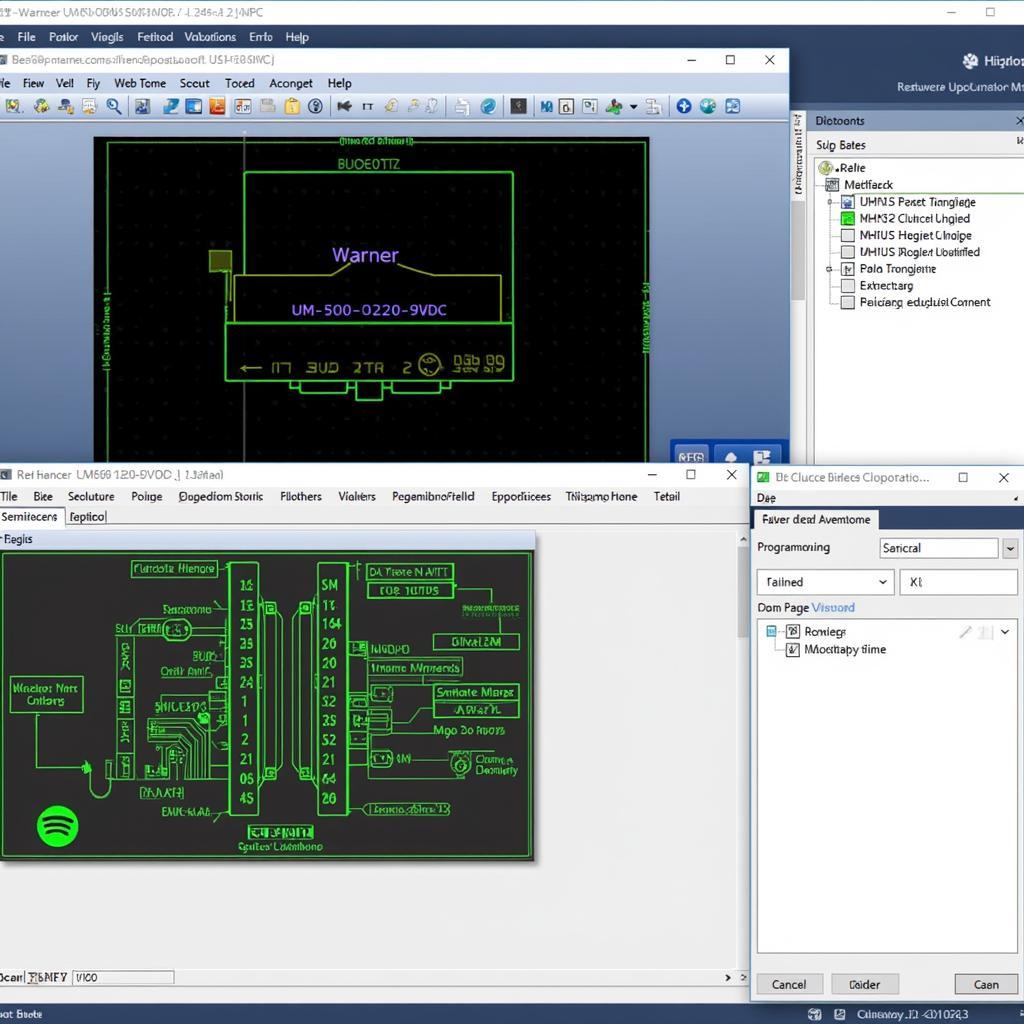

Remote Diagnostics and Software Solutions

For more advanced troubleshooting, remote diagnostics and software tools can be employed. These tools can access the module’s internal data and provide detailed insights into its operation, facilitating quicker and more accurate diagnosis. Remote programming and software updates can also address certain issues without requiring physical access to the module.

What are the symptoms of a failing Warner clutch brake module?

Symptoms include jerky movements, inaccurate positioning, and complete system failure.

How can I test the Warner clutch brake module UM50-1020-90VDC?

Test the module by verifying power supply, checking wiring, inspecting input signals, measuring coil resistance, and inspecting internal components.

“Regular preventative maintenance, including checking wiring and connections, can significantly extend the lifespan of your Warner clutch brake module and prevent costly downtime,” says John Smith, Senior Automation Engineer at Industrial Automation Solutions Inc.

Remote Diagnostics Software Interface for Warner UM50-1020-90VDC

Remote Diagnostics Software Interface for Warner UM50-1020-90VDC

“Using remote diagnostics and software updates is a game-changer in troubleshooting these modules. It allows us to identify and address problems much faster than traditional methods,” adds Maria Garcia, Lead Field Service Technician at Advanced Motion Control Systems.

Conclusion

Troubleshooting the Warner clutch brake module UM50-1020-90VDC requires a systematic approach, from basic checks to advanced diagnostics. By following the steps outlined in this guide, you can effectively identify the cause of the problem and implement the necessary repairs or replacements, minimizing downtime and ensuring optimal performance of your equipment. Remember that preventative maintenance and utilizing remote diagnostic tools can further enhance the reliability and longevity of your Warner clutch brake module UM50-1020-90VDC.

FAQ

- What is the typical lifespan of a Warner UM50-1020-90VDC clutch brake module?

- Are replacement parts readily available for this module?

- Can I repair the module myself, or should I contact a qualified technician?

- What are some common causes of coil failure in the UM50-1020-90VDC module?

- How can I prevent future issues with my Warner clutch brake module?

- Are there any safety precautions I should take when working with this module?

- Where can I find the technical specifications for the UM50-1020-90VDC module?