Mercedes-Benz service codes can seem complex initially, but by the end of this comprehensive guide from CARDIAGTECH.NET, you’ll have a much clearer understanding. Whether you’re a seasoned mechanic or a Mercedes owner seeking to decipher your car’s maintenance needs, this List Of Mercedes Service Codes will help you to carry out the necessary repairs effectively and successfully. Equip yourself with the knowledge to understand and address your vehicle’s service requirements and enhance your automotive repair services with our support.

Contents

- 1. Understanding the Mercedes-Benz Service System

- 1.1 Initial Assyst Service System

- 1.2 Evolution to Assyst Plus

- 1.3 Numerical and Alphabetical Combinations

- 2. Decoding Mercedes-Benz Workshop Codes

- 2.1 Accessing the Workshop Menu

- 2.2 Examples of Service Codes

- 3. Comprehensive List of Mercedes-Benz Service Items

- 3.1 Additional Service Items and Their Codes

- 3.2 Accessing Service Sheets

- 4. Detailed List of Mercedes-Benz Display Codes, Workshop Codes, and Service Items

- 4.1 Comprehensive Service Code Guide

- 5. Real-World Application: Decoding Service Requirements

- 5.1 Example Scenario

- 5.2 Decoding the Service Items

- 5.3 Additional Checks

- 6. The Importance of Using the Right Diagnostic Tools

- 6.1 Benefits of Quality Diagnostic Tools

- 6.2 Essential Diagnostic Tools for Mercedes-Benz

- 6.3 Where to Find Reliable Diagnostic Tools

- 7. Navigating Common Challenges in Mercedes-Benz Servicing

- 7.1 Common Issues Encountered

- 7.2 Tips for Overcoming Challenges

- 7.3 How CARDIAGTECH.NET Can Help

- 8. Optimizing Your Mercedes-Benz Service with CARDIAGTECH.NET

- 8.1 Diagnostic Tools Available

- 8.2 Benefits of Choosing CARDIAGTECH.NET

- 8.3 How to Get Started

- 9. Maximizing Efficiency and Accuracy in Mercedes-Benz Repairs

- 9.1 Step-by-Step Repair Procedures

- 9.2 Utilizing Mercedes-Benz Resources

- 9.3 Training and Certification

- 10. How to Interpret Mercedes-Benz Service Records

- 10.1 Key Elements in Service Records

- 10.2 Interpreting Service Codes

- 10.3 Importance of Accurate Service Records

- 10.4 Utilizing CARDIAGTECH.NET for Service Record Analysis

- 11. Latest Innovations in Mercedes-Benz Diagnostic Technology

- 11.1 Remote Diagnostics

- 11.2 Artificial Intelligence (AI) in Diagnostics

- 11.3 Augmented Reality (AR) Applications

- 11.4 Enhanced Connectivity

- 11.5 Integration of Machine Learning

- 11.6 CARDIAGTECH.NET and Technological Advancements

- 12. Addressing Specific Mercedes-Benz Model Issues

- 12.1 Common Issues by Model

- 12.2 Diagnostic Tips for Model-Specific Issues

- 12.3 CARDIAGTECH.NET Solutions

- 13. Essential Maintenance Tasks to Prevent Costly Repairs

- 13.1 Regular Oil Changes

- 13.2 Brake System Inspection and Maintenance

- 13.3 Fluid Level Checks and Top-Ups

- 13.4 Tire Rotation and Alignment

- 13.5 Air Filter Replacement

- 13.6 CARDIAGTECH.NET Support

- 14. Understanding Mercedes-Benz Diagnostic Trouble Codes (DTCs)

- 14.1 Types of DTCs

- 14.2 Reading DTCs

- 14.3 Interpreting DTCs

- 14.4 Clearing DTCs

- 14.5 Resources for DTC Information

- 15. When to Seek Professional Help

- 15.1 Complex Diagnostic Issues

- 15.2 Major Repairs

- 15.3 Safety-Critical Systems

- 15.4 Warranty Concerns

- 15.5 Finding a Qualified Technician

- 15.6 Partnering with CARDIAGTECH.NET

- 16.1 Electric Vehicle (EV) Servicing

- 16.2 Over-the-Air (OTA) Updates

- 16.3 Advanced Driver Assistance Systems (ADAS) Calibration

- 16.4 Predictive Maintenance

1. Understanding the Mercedes-Benz Service System

The Mercedes-Benz service system, known as “Assyst,” initially revolved around letters like ‘A’ and ‘B’ to indicate service types. These services are often referred to as “1 spanner” or “2 spanner” services on older models (pre-2005).

1.1 Initial Assyst Service System

The original Assyst system included:

- A Service (Minor): Engine oil and filter change, minor vehicle inspection.

- B Service (Major): Engine oil and filter change, pollen filter replacement, major vehicle inspection.

In addition to these, there were ‘Additional service items’ based on age or mileage, including:

- Air filter replacement

- Fuel filter replacement

- Brake fluid change

- Coolant change

- Spark plug replacement

- Gearbox oil/filter change

This evolved to ‘Assyst Plus’ to incorporate time and wear-specific maintenance and special equipment needs.

1.2 Evolution to Assyst Plus

The ‘Assyst Plus’ system was introduced, first appearing on models like the 211 E-Class, 251 R-Class, 164 ML-Class, and 169 A-Class. This system expanded the service codes to include letters up to ‘H’, leading to services like A, B, C, D, E, F, G, or H.

1.3 Numerical and Alphabetical Combinations

To reduce confusion, models from around 2008 (such as the 204 C-Class and 212 E-Class) began using numbers or letters after ‘A’ or ‘B’ to indicate when ‘Additional service items’ were due. This resulted in combinations like A1, B1, A5, B5, A3, AK, AC, B0, etc. This system aligns with the introduction of the Mercedes-Benz Digital Service Book (DSB) around the same time.

Understanding these codes is crucial for properly maintaining your Mercedes-Benz. For reliable diagnostic tools and support, visit CARDIAGTECH.NET.

Mercedes Assyst service display indicating service items

Mercedes Assyst service display indicating service items

2. Decoding Mercedes-Benz Workshop Codes

In addition to the letter and number combinations, there’s also a ‘Workshop code’ for each service item. This workshop code can be accessed via the instrument cluster’s workshop menu.

2.1 Accessing the Workshop Menu

To access the workshop menu on most cars with a 12-button steering wheel:

- Turn the ignition to position 1.

- Ensure the overall mileage is displayed.

- Press and hold the call answer button.

- While holding the call answer button, press and hold the OK button.

2.2 Examples of Service Codes

Let’s look at some examples to illustrate how these codes work:

- A Service: The service code is ‘505’, which translates to service item 1 (minor inspection) & service item 3 (engine oil and filter change).

- B1 Service: The service code is ‘E0E’, which translates to service item 2 (major inspection), service item 3 (engine oil and filter change), & service item 4 (brake fluid change).

From these examples, we can deduce that:

- Service item 1 indicates an ‘A’ service.

- Service item 2 indicates a ‘B’ service.

- Service item 3 (engine oil and filter change) is required at every service.

Understanding these codes helps in accurately identifying the necessary maintenance tasks for your Mercedes-Benz. At CARDIAGTECH.NET, we provide the tools and knowledge you need for efficient vehicle diagnostics and repairs.

3. Comprehensive List of Mercedes-Benz Service Items

To further clarify the service requirements, here is an extensive list of additional service items that you might encounter, along with their corresponding service numbers:

3.1 Additional Service Items and Their Codes

| Service Item | Description |

|---|---|

| 4 | Brake fluid change |

| 5 | Combination filter (additional filter on some models) |

| 8 | Air filter replacement, sometimes differential oil |

| 10 | Sunroof guide rails clean / regrease |

| 11 | Fuel filter replacement |

| 12 | Replace spark plugs |

| 13 | Engine coolant renewal |

| 14 | Main coolant circuit (possibly cooling system for hybrids?) |

| 15 | Towing hitch lubrication |

| 20 | Gearbox oil change / filter renewal |

| 24 | Cambelt replacement / Water pump replacement |

Important Note: Always cross-reference these items with the service sheet specific to your vehicle, as there may be crucial details that you need to be aware of. Service sheets can be found via WIS (Workshop Information System) or Autodata.

3.2 Accessing Service Sheets

Accessing and understanding these service sheets can greatly enhance your vehicle maintenance and repair tasks. For top-quality diagnostic tools and comprehensive support, CARDIAGTECH.NET is your reliable partner.

Here is an example of the W212 Service Sheet Overview:

Service-Sheet-W212

Download

4. Detailed List of Mercedes-Benz Display Codes, Workshop Codes, and Service Items

Below is a detailed list consolidating display codes, workshop codes, and corresponding service items. Note that this list is not exhaustive, but it serves as a valuable guide.

4.1 Comprehensive Service Code Guide

| Display Code | Workshop Code | Service Items |

|---|---|---|

| A | 505 | Service items 1, 3 |

| A1 | D0D | Service items 1, 3, 4 |

| A2 | 550A | |

| A3 | Service items 1, 3, 8, 11 (Diesel engine) | |

| A3 | Service items 1, 3, 8, 12 (Petrol engine) | |

| A4 | D50J | Service items 1, 3, 8, 10, 11 |

| A5 | ||

| A6 | DD0S | Service items 1, 3, 4, 8, 10, 11 |

| A7 | G50M | Service items 1, 3, 20 |

| A8 | Q50V | Service items 1, 3, 10, 20 |

| A9 | GD0V | Service items 1, 3, 4, 20 |

| A0 | 850D | Service items 1, 3, 10 |

| AC | QD051 | Service items 1, 3, 4, 10, 20 |

| AF | KD001 | Service items 1, 3, 4, 8, 12, 20 |

| AH | 801050E | Service items 1, 3, 13, 24 |

| AG | VD0A1 | Service items 1, 3, 4, 8, 10, 11, 20 |

| AK | 10D0E | Service items 1, 3, 13 |

| AP | 15D0K | |

| B | 606 | Service items 2, 3 |

| B1 | E0E | Service items 2, 3, 4 |

| B2 | 8E0N | Service items 2, 3, 4, 10 |

| B3 | 560B | Service items 2, 3, 8, 11 |

| B4 | B60H | Service items 2, 3, 8, 10, 11 |

| B5 | 5E0K | Service items 2, 3, 4, 8, 11 |

| B5 | 3E0H | Service items 2, 3, 4, 8, 12 |

| B6 | DE0T | Service items 2, 3, 4, 8, 10, 11 |

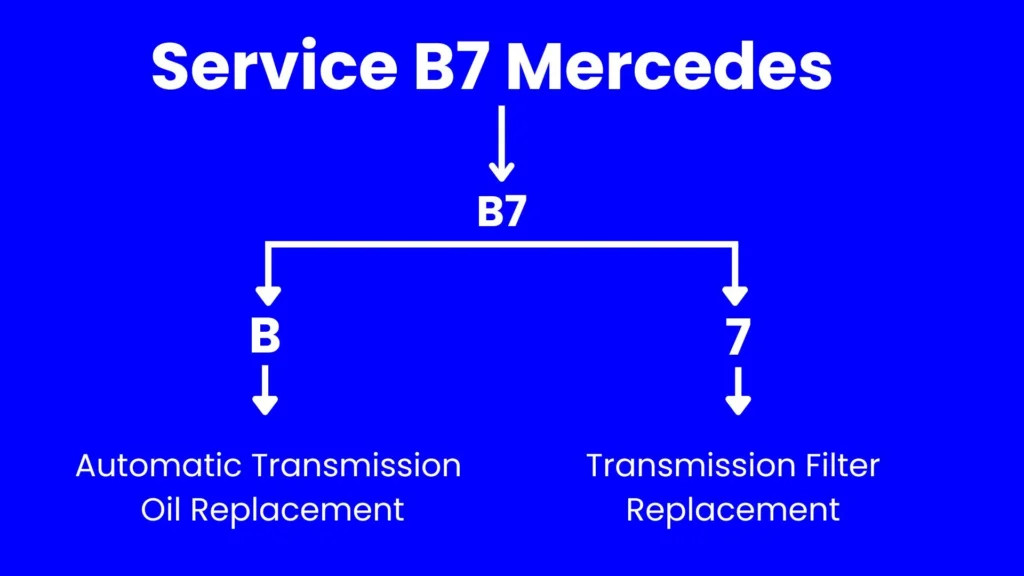

| B7 | G60N | Service items 2, 3, 20 |

| B7 | GN061 | Service items 2, 3, 15, 20 |

| B8 | Q60W | Service items 2, 3, 10, 20 |

| B9 | GE0W | Service items 2, 3, 4, 20 |

| B0 | 1607 | Service items 2, 3, 8 |

| B0 | 960F | Service items, 2, 3, 8, 10 (on a GL63) |

| BD | M60T | Service items 2, 3, 8, 11, 20 |

| BE | V6031 | Service items 2, 3, 8, 10, 11, 20 |

| BF | ||

| BK | 10E0F | Service items 2, 3, 4, 13 |

| BK | 14E0K | Service items 2, 3, 4, 11, 13 (Reader Submitted, W246) |

| BS | 1Q60X | Service items 2, 3, 10, 13, 20 |

This comprehensive list is a valuable resource for Mercedes-Benz owners and technicians alike. For further assistance and top-of-the-line diagnostic tools, CARDIAGTECH.NET is here to support you.

5. Real-World Application: Decoding Service Requirements

Let’s consider a practical scenario to illustrate how to decode service requirements using the information provided.

5.1 Example Scenario

Suppose your Mercedes-Benz indicates that it is due for a ‘BS’ service. What does this mean?

- Access the Workshop Menu: Follow the steps outlined earlier to access the workshop menu on your instrument cluster.

- Identify the Workshop Code: From the workshop menu, you find the following information:

- Next service: BS

- Workshop code: 1Q60X

- Service items: 2, 3, 10, 13, 20

5.2 Decoding the Service Items

Using the workshop code and service items, we can break down the service requirements as follows:

- B Service (Items 2 & 3):

- Item 2: Major inspection

- Item 3: Engine oil and filter change

- Additional Service Items:

- Item 10: Panoramic roof mechanism cleaned and regreased

- Item 13: Coolant renewed

- Item 20: Gearbox oil/filter change

Therefore, the ‘BS’ service requires a major inspection, engine oil and filter change, cleaning and regreasing of the panoramic roof mechanism, coolant renewal, and a gearbox oil/filter change.

5.3 Additional Checks

Don’t forget to check other vehicle data, such as AdBlue levels, to ensure comprehensive maintenance.

By following these steps, you can accurately decode the service requirements for your Mercedes-Benz and ensure that all necessary maintenance tasks are performed. For professional diagnostic tools and support, CARDIAGTECH.NET is your trusted partner.

Mercedes service information displayed on the instrument cluster

Mercedes service information displayed on the instrument cluster

6. The Importance of Using the Right Diagnostic Tools

Having a detailed list of Mercedes service codes is beneficial, but to effectively diagnose and address these service needs, you need the right diagnostic tools. High-quality tools ensure accuracy and efficiency in your repair and maintenance work.

6.1 Benefits of Quality Diagnostic Tools

Investing in professional-grade diagnostic tools offers several advantages:

- Accurate Readings: Precise diagnostic information to pinpoint issues quickly.

- Efficiency: Faster diagnosis and repair times, increasing productivity.

- Comprehensive Analysis: Detailed insights into your vehicle’s health.

- User-Friendly Interface: Easy-to-navigate software for efficient use.

- Wide Compatibility: Works across various Mercedes-Benz models.

6.2 Essential Diagnostic Tools for Mercedes-Benz

Some essential diagnostic tools include:

- OBD-II Scanners: For reading and clearing diagnostic trouble codes (DTCs).

- Mercedes-Benz Specific Diagnostic Systems: Tools like the Mercedes-Benz Star Diagnosis system for in-depth analysis.

- Multimeters: For electrical testing and troubleshooting.

- Pressure Testers: For checking fluid pressures in systems like brakes and coolant.

6.3 Where to Find Reliable Diagnostic Tools

For top-quality diagnostic tools tailored for Mercedes-Benz vehicles, CARDIAGTECH.NET offers a wide range of options to meet your needs.

7. Navigating Common Challenges in Mercedes-Benz Servicing

Servicing Mercedes-Benz vehicles can present unique challenges. Being aware of these issues and having the right tools and information can make the process smoother.

7.1 Common Issues Encountered

Some common issues include:

- Complex Electronics: Mercedes-Benz vehicles have intricate electronic systems that require specialized diagnostic tools.

- Specific Service Requirements: Adhering to Mercedes-Benz’s specific service intervals and procedures is crucial for maintaining warranty and performance.

- Component Compatibility: Ensuring that replacement parts are compatible with the vehicle’s specifications.

- Software Updates: Keeping the vehicle’s software up to date for optimal performance.

7.2 Tips for Overcoming Challenges

Here are some tips to help you overcome these challenges:

- Invest in Training: Continuous training on Mercedes-Benz systems and diagnostic procedures.

- Use Genuine Parts: Opt for genuine Mercedes-Benz parts to ensure compatibility and reliability.

- Stay Updated: Keep up with the latest service bulletins and technical updates from Mercedes-Benz.

- Leverage Online Resources: Utilize online forums and communities to share knowledge and solutions.

7.3 How CARDIAGTECH.NET Can Help

CARDIAGTECH.NET provides the tools, information, and support you need to tackle these challenges effectively. Our extensive range of diagnostic tools and expert advice will help you navigate the complexities of Mercedes-Benz servicing.

Image of Mercedes dashboard displaying service due message

Image of Mercedes dashboard displaying service due message

8. Optimizing Your Mercedes-Benz Service with CARDIAGTECH.NET

CARDIAGTECH.NET offers a comprehensive suite of diagnostic tools and resources designed to enhance your Mercedes-Benz service capabilities.

8.1 Diagnostic Tools Available

We provide a range of diagnostic tools, including:

- OBD-II Scanners: Advanced scanners with Mercedes-Benz specific capabilities.

- Mercedes-Benz Star Diagnosis System: Comprehensive diagnostic systems for in-depth vehicle analysis.

- Specialized Tools: Tools for specific tasks like ECU programming, key programming, and more.

8.2 Benefits of Choosing CARDIAGTECH.NET

When you choose CARDIAGTECH.NET, you benefit from:

- High-Quality Products: Reliable and accurate diagnostic tools.

- Expert Support: Knowledgeable support staff to assist you with any questions or issues.

- Competitive Pricing: Affordable options to fit your budget.

- Fast Shipping: Quick and efficient delivery to get you the tools you need promptly.

8.3 How to Get Started

Getting started with CARDIAGTECH.NET is easy. Simply visit our website, browse our selection of diagnostic tools, and place your order. Our team is ready to help you find the perfect tools for your Mercedes-Benz service needs.

9. Maximizing Efficiency and Accuracy in Mercedes-Benz Repairs

To maximize efficiency and accuracy in Mercedes-Benz repairs, it’s crucial to follow established procedures and utilize resources effectively. Here’s a detailed guide on optimizing your repair processes.

9.1 Step-by-Step Repair Procedures

Following a structured approach can significantly improve repair outcomes:

- Initial Assessment: Begin with a thorough inspection of the vehicle. Document all symptoms and any unusual findings.

- Diagnostic Scan: Use a high-quality OBD-II scanner or a Mercedes-Benz specific diagnostic tool to retrieve diagnostic trouble codes (DTCs). Record all codes accurately.

- Code Analysis: Consult the Mercedes-Benz service manual or online databases to understand the meaning of each DTC. Prioritize codes based on their potential impact on vehicle performance and safety.

- Component Testing: Perform targeted tests on components related to the identified DTCs. Use multimeters, pressure testers, and other diagnostic tools to verify component functionality.

- Repair or Replacement: Based on the test results, either repair the faulty component or replace it with a genuine Mercedes-Benz part to ensure compatibility and reliability.

- Post-Repair Testing: After completing the repair or replacement, perform another diagnostic scan to ensure that all DTCs have been resolved. Conduct a road test to verify that the vehicle is functioning correctly under various driving conditions.

- Documentation: Maintain detailed records of all diagnostic steps, test results, and repair procedures. This documentation can be valuable for future reference and warranty claims.

9.2 Utilizing Mercedes-Benz Resources

Leverage official resources to enhance repair accuracy:

- Service Manuals: Always refer to the official Mercedes-Benz service manuals for detailed repair procedures and specifications.

- Technical Service Bulletins (TSBs): Stay updated with the latest TSBs from Mercedes-Benz, which provide information on common issues and recommended solutions.

- Online Databases: Utilize online databases like WIS (Workshop Information System) and Autodata for access to wiring diagrams, component locations, and repair tips.

9.3 Training and Certification

Invest in ongoing training to keep up with evolving automotive technology:

- Mercedes-Benz Training Programs: Participate in training programs offered by Mercedes-Benz to gain expertise in specific vehicle systems and repair procedures.

- Industry Certifications: Obtain certifications from organizations like ASE (Automotive Service Excellence) to demonstrate your knowledge and skills to customers and employers.

By integrating these strategies into your repair workflow, you can significantly enhance efficiency, accuracy, and customer satisfaction in your Mercedes-Benz service operations. At CARDIAGTECH.NET, we are committed to providing the tools and resources you need to achieve excellence in automotive repair.

Mercedes-Benz diagnostic tool in use

Mercedes-Benz diagnostic tool in use

10. How to Interpret Mercedes-Benz Service Records

Understanding and interpreting Mercedes-Benz service records is essential for both vehicle owners and technicians. These records provide a detailed history of maintenance and repairs, helping to ensure the vehicle’s longevity and optimal performance.

10.1 Key Elements in Service Records

Here are the key elements you’ll typically find in Mercedes-Benz service records:

- Date of Service: The date when the service was performed.

- Mileage: The vehicle’s mileage at the time of service.

- Service Type: A description of the service performed (e.g., A Service, B Service, oil change, brake replacement).

- Service Codes: Specific codes that indicate the tasks performed (e.g., 505 for A Service, E0E for B1 Service).

- Parts Used: A list of all parts replaced during the service, including part numbers.

- Technician Notes: Detailed notes from the technician about the vehicle’s condition and any issues found.

- Workshop Code: The code associated with the specific service items performed.

10.2 Interpreting Service Codes

Using the service code lists provided earlier in this guide, you can interpret the specific maintenance tasks that were performed during each service. For example, if a service record shows a code of “D0D,” you can refer to the list to understand that this includes service items 1, 3, and 4, which correspond to a minor inspection, engine oil and filter change, and brake fluid change.

10.3 Importance of Accurate Service Records

Accurate and complete service records are important for several reasons:

- Vehicle Maintenance: They provide a clear history of the vehicle’s maintenance, helping to ensure that all necessary services are performed on time.

- Warranty Claims: They serve as proof of maintenance for warranty claims.

- Resale Value: They can increase the resale value of the vehicle, as potential buyers can see that the vehicle has been well-maintained.

- Diagnostic Assistance: They can assist technicians in diagnosing current issues by providing insights into previous repairs and maintenance.

10.4 Utilizing CARDIAGTECH.NET for Service Record Analysis

CARDIAGTECH.NET can help you analyze Mercedes-Benz service records by providing the tools and information you need to interpret service codes and understand the vehicle’s maintenance history. Our expert support team can assist you in deciphering complex service records and identifying potential issues.

11. Latest Innovations in Mercedes-Benz Diagnostic Technology

Keeping up with the latest innovations in Mercedes-Benz diagnostic technology is crucial for providing efficient and accurate service. Here’s an overview of recent advancements:

11.1 Remote Diagnostics

Remote diagnostics allows technicians to diagnose and troubleshoot vehicle issues remotely, saving time and reducing the need for physical inspections.

- How it Works: Technicians use specialized software and telematics data to access the vehicle’s control units, read diagnostic codes, and perform tests remotely.

- Benefits: Reduces downtime, enables quicker repairs, and allows for expert consultation from anywhere in the world.

11.2 Artificial Intelligence (AI) in Diagnostics

AI-powered diagnostic tools can analyze vast amounts of data to identify patterns, predict potential failures, and provide technicians with actionable insights.

- How it Works: AI algorithms analyze data from various sensors and systems to detect anomalies and predict component failures.

- Benefits: Enhances diagnostic accuracy, reduces the risk of misdiagnosis, and enables proactive maintenance.

11.3 Augmented Reality (AR) Applications

Augmented Reality (AR) applications are transforming how technicians perform repairs by providing real-time, interactive guidance overlaid on the vehicle.

- How it Works: Technicians use AR-enabled devices, such as tablets or smart glasses, to view step-by-step repair instructions, wiring diagrams, and component information directly on the vehicle.

- Benefits: Improves repair accuracy, reduces errors, and enhances technician training.

11.4 Enhanced Connectivity

Modern Mercedes-Benz vehicles feature enhanced connectivity options, including over-the-air (OTA) updates and cloud-based diagnostics.

- How it Works: OTA updates allow vehicle software to be updated remotely, while cloud-based diagnostics enable real-time monitoring and analysis of vehicle performance.

- Benefits: Keeps vehicle systems up-to-date, enables proactive maintenance, and improves overall vehicle performance.

11.5 Integration of Machine Learning

Machine learning algorithms are being integrated into diagnostic tools to improve their ability to learn from past experiences and adapt to new situations.

- How it Works: Machine learning algorithms analyze diagnostic data to identify patterns and improve diagnostic accuracy over time.

- Benefits: Enhances diagnostic efficiency, reduces diagnostic time, and improves overall repair outcomes.

11.6 CARDIAGTECH.NET and Technological Advancements

CARDIAGTECH.NET stays at the forefront of these technological advancements, offering the latest diagnostic tools and resources to help technicians provide superior service.

Mercedes-Benz technician using diagnostic tools

Mercedes-Benz technician using diagnostic tools

12. Addressing Specific Mercedes-Benz Model Issues

Different Mercedes-Benz models often have their own unique set of common issues. Being aware of these model-specific problems can help technicians diagnose and repair them more effectively.

12.1 Common Issues by Model

| Model Series | Common Issues |

|---|---|

| W204 (C-Class) | Steering lock malfunctions, timing chain issues (on certain engines), fuel injector problems |

| W212 (E-Class) | Air suspension failures, oil leaks (especially around the valve cover and oil filter housing), transmission issues |

| W221 (S-Class) | Airmatic suspension problems, electronic control unit (ECU) failures, fuel pump malfunctions |

| W166 (M-Class/GLE) | Transfer case failures, oil leaks (particularly from the rear main seal), turbocharger issues (on certain engines) |

| W205 (C-Class) | MBUX infotainment system glitches, electrical issues (including sensor failures), suspension component wear |

12.2 Diagnostic Tips for Model-Specific Issues

- W204 (C-Class): For steering lock malfunctions, check the electronic steering lock (ESL) module and wiring connections. For timing chain issues, listen for unusual noises from the engine and inspect the chain tensioner.

- W212 (E-Class): For air suspension failures, inspect the air struts, compressor, and air lines for leaks. For oil leaks, use a UV dye to pinpoint the source of the leak.

- W221 (S-Class): For Airmatic suspension problems, check the air struts, compressor, and valve block. For ECU failures, perform a thorough diagnostic scan to identify the affected control unit.

- W166 (M-Class/GLE): For transfer case failures, listen for unusual noises or vibrations when shifting into four-wheel drive. For oil leaks, inspect the rear main seal and other potential leak sources.

- W205 (C-Class): For MBUX infotainment system glitches, check for software updates and perform a system reset. For electrical issues, use a multimeter to test sensor circuits and wiring connections.

12.3 CARDIAGTECH.NET Solutions

CARDIAGTECH.NET provides specialized diagnostic tools and resources for addressing model-specific issues in Mercedes-Benz vehicles. Our team of experts can provide guidance and support to help you diagnose and repair these problems effectively.

13. Essential Maintenance Tasks to Prevent Costly Repairs

Preventive maintenance is crucial for avoiding expensive repairs and ensuring the longevity of your Mercedes-Benz. Here are some essential maintenance tasks that should be performed regularly.

13.1 Regular Oil Changes

Changing the engine oil and filter at the recommended intervals (typically every 5,000 to 10,000 miles) is essential for lubricating engine components and preventing wear.

- Benefits: Extends engine life, improves fuel efficiency, and reduces the risk of engine damage.

- Tools Needed: Oil filter wrench, socket set, drain pan, new oil filter, and the correct type and quantity of engine oil.

13.2 Brake System Inspection and Maintenance

Regularly inspect the brake pads, rotors, calipers, and brake lines for wear and damage. Replace worn components as needed to ensure safe braking performance.

- Benefits: Maintains safe braking performance, prevents brake fade, and reduces the risk of accidents.

- Tools Needed: Brake pad wear gauge, caliper tool, socket set, torque wrench, and brake fluid.

13.3 Fluid Level Checks and Top-Ups

Check and top up fluid levels regularly, including engine coolant, brake fluid, power steering fluid, and windshield washer fluid.

- Benefits: Prevents overheating, maintains proper braking and steering performance, and ensures optimal visibility.

- Tools Needed: Funnel, fluid level indicators, and the correct type of fluid for each system.

13.4 Tire Rotation and Alignment

Rotate the tires every 6,000 to 8,000 miles to ensure even wear and extend tire life. Perform a wheel alignment as needed to prevent uneven tire wear and improve handling.

- Benefits: Extends tire life, improves fuel efficiency, and enhances handling and stability.

- Tools Needed: Jack, lug wrench, torque wrench, alignment rack, and alignment tools.

13.5 Air Filter Replacement

Replace the engine air filter and cabin air filter at the recommended intervals (typically every 12,000 to 15,000 miles) to ensure proper airflow and air quality.

- Benefits: Improves engine performance, fuel efficiency, and air quality inside the vehicle.

- Tools Needed: Screwdriver, socket set, and new air filters.

13.6 CARDIAGTECH.NET Support

CARDIAGTECH.NET offers a wide range of maintenance tools and resources to help you perform these essential tasks and keep your Mercedes-Benz running smoothly.

Mercedes-Benz engine bay

Mercedes-Benz engine bay

14. Understanding Mercedes-Benz Diagnostic Trouble Codes (DTCs)

Diagnostic Trouble Codes (DTCs) are codes stored in your vehicle’s computer that indicate a problem has been detected in a specific system or component. Understanding these codes is essential for diagnosing and repairing issues effectively.

14.1 Types of DTCs

DTCs are typically categorized into several types, including:

- Powertrain Codes (P Codes): Relate to the engine, transmission, and related systems.

- Chassis Codes (C Codes): Relate to the braking system, suspension, and steering.

- Body Codes (B Codes): Relate to the body control systems, such as lights, windows, and doors.

- Network Codes (U Codes): Relate to the communication network between different control units.

14.2 Reading DTCs

To read DTCs, you’ll need an OBD-II scanner. Plug the scanner into the OBD-II port (typically located under the dashboard) and follow the scanner’s instructions to retrieve the codes.

14.3 Interpreting DTCs

Each DTC consists of a five-character code that provides information about the nature and location of the problem. For example, a code like “P0300” indicates a random or multiple cylinder misfire.

14.4 Clearing DTCs

After repairing the issue, you can clear the DTCs using the OBD-II scanner. However, it’s important to ensure that the problem has been resolved before clearing the codes, as they may reappear if the underlying issue persists.

14.5 Resources for DTC Information

- Mercedes-Benz Service Manuals: Provide detailed information about DTCs and troubleshooting procedures.

- Online Databases: Websites like OBD-Codes.com and others offer comprehensive information about DTCs and their possible causes.

- CARDIAGTECH.NET: Offers diagnostic tools and resources to help you read, interpret, and clear DTCs effectively.

15. When to Seek Professional Help

While many maintenance and repair tasks can be performed by skilled DIYers, there are certain situations where it’s best to seek professional help from a qualified Mercedes-Benz technician.

15.1 Complex Diagnostic Issues

If you’re facing complex diagnostic issues that you can’t resolve with basic tools and knowledge, it’s time to consult a professional. Complex issues may involve intricate electronic systems, specialized diagnostic equipment, or advanced troubleshooting procedures.

15.2 Major Repairs

Major repairs, such as engine overhauls, transmission replacements, or suspension repairs, typically require specialized tools, knowledge, and experience. Attempting these repairs without the proper expertise can lead to further damage or safety risks.

15.3 Safety-Critical Systems

Any repairs involving safety-critical systems, such as brakes, steering, or airbags, should be performed by a qualified technician. These systems require precise knowledge and attention to detail to ensure they function correctly and safely.

15.4 Warranty Concerns

If your vehicle is still under warranty, it’s important to have repairs performed by an authorized Mercedes-Benz dealer or service center to avoid voiding the warranty.

15.5 Finding a Qualified Technician

- Authorized Dealers: Offer specialized knowledge and genuine parts.

- Independent Repair Shops: Look for shops specializing in European vehicles, particularly Mercedes-Benz.

- Certifications: Ensure the technician is certified by organizations like ASE.

- Reviews and Recommendations: Check online reviews and ask for recommendations from friends or family.

15.6 Partnering with CARDIAGTECH.NET

At CARDIAGTECH.NET, we are dedicated to supporting both DIY enthusiasts and professional technicians with top-quality diagnostic tools and resources. Whether you’re performing routine maintenance or tackling complex repairs, we have the tools and expertise to help you succeed.

Mercedes-Benz service center

Mercedes-Benz service center

The automotive industry is constantly evolving, and Mercedes-Benz servicing is no exception. Here are some future trends to watch for:

16.1 Electric Vehicle (EV) Servicing

As Mercedes-Benz continues to expand its lineup of electric vehicles, servicing EVs will become increasingly important. This will require specialized knowledge, tools, and safety procedures for working with high-voltage systems.

16.2 Over-the-Air (OTA) Updates

Over-the-air (OTA) updates will become more common, allowing Mercedes-Benz to remotely update vehicle software and firmware. This will enable them to address issues, improve performance, and add new features without requiring a visit to the service center.

16.3 Advanced Driver Assistance Systems (ADAS) Calibration

Advanced Driver Assistance Systems (ADAS), such as adaptive cruise control, lane departure warning, and automatic emergency braking, will require regular calibration to ensure they function correctly. This will involve specialized equipment and procedures.

16.4 Predictive Maintenance

Predictive maintenance will use data analytics and machine learning to predict when components are likely to fail. This will