How to Fix Clear Coat Damage on Your Car: A Comprehensive Guide

Clear coat is the unsung hero of your car’s paint job, acting as a vital protective layer. It shields the vibrant color coat beneath from the daily onslaught of environmental hazards and physical abrasions. More importantly, it’s the barrier that defends the metal body of your vehicle from rust and corrosion. Neglecting clear coat damage can lead to escalating problems and more costly repairs down the line.

If your car’s clear coat is showing signs of wear and tear, understanding how to repair it is crucial. This guide provides a comprehensive, step-by-step approach to fixing clear coat damage and restoring your car’s finish.

Understanding the Culprits: What Damages Clear Coat?

Before diving into the repair process, it’s essential to understand the common causes of clear coat damage. Identifying these culprits can help you prevent future issues and maintain your car’s pristine condition.

-

Physical Abrasions: Road debris, such as rocks and gravel, are notorious for causing chips and scratches that penetrate the clear coat. These impacts can expose the color coat and even the bare metal underneath, leading to further damage if left unattended.

-

UV Radiation: The sun, while enjoyable, is a significant threat to your car’s clear coat. Prolonged exposure to ultraviolet (UV) radiation causes a slow, cumulative breakdown of the clear coat. The heat from the sun can cause paint layers to separate, leading to fading, cracking, and peeling over time.

-

Chemical Exposure: Everyday substances can be surprisingly harmful to your clear coat. Bug splatter, tree sap, gasoline spills, and even harsh car wash chemicals can degrade the clear coat. These substances contain acids and solvents that can break down the protective layer, making it more vulnerable to damage.

-

Improper Application: Sometimes, the issue isn’t external factors but the clear coat itself. A poor or uneven application of clear coat during manufacturing or a previous repair can lead to premature chipping and peeling. Areas that are too thin or improperly cured are more susceptible to failure.

Essential Tools and Materials for Clear Coat Repair

Having the right tools and materials at hand is crucial for a successful clear coat repair. Gather these items before you begin:

- Car Wash Supplies: Start with a clean surface. You’ll need car soap, a wash mitt to gently scrub the area, and absorbent towels for drying.

- Sandpaper or Automotive Scotch-Brite Pads: For removing damaged clear coat and creating a smooth surface for the new layer. Fine-grit sandpaper (1500-grit, 2000-grit, 3000-grit) and automotive Scotch-Brite pads are ideal.

- Isopropyl Alcohol: A cleaning agent to remove any residue, wax, or grease before applying the new clear coat, ensuring proper adhesion.

- Automotive Clear Coat Spray Paint: Choose a high-quality clear coat spray paint that is compatible with your car’s original finish. Ensure it’s designed for automotive use for durability and weather resistance.

- Masking Tape: To protect surrounding areas from overspray and define the repair area precisely. Automotive masking tape is designed to leave clean lines without damaging existing paint.

- Masking Paper or Film: For larger areas surrounding the repair, providing broader protection from overspray.

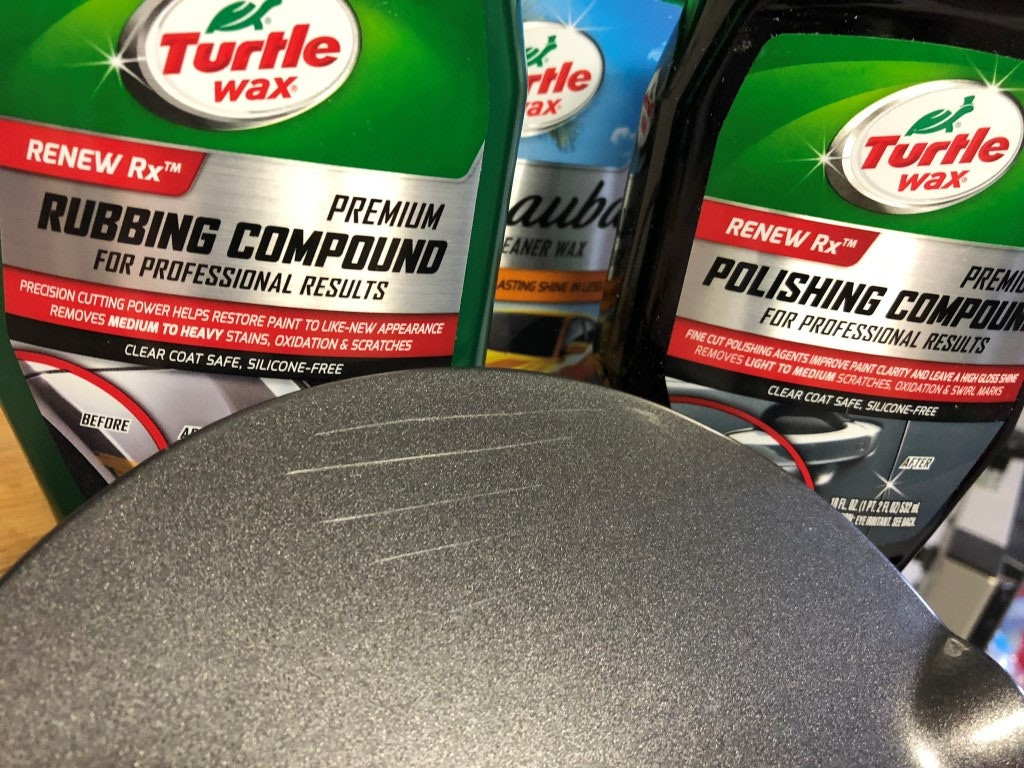

- Buffer & Wax: For the final step of blending and polishing the repaired area to match the surrounding paint and restore shine. A dual-action polisher is recommended for ease of use and safety.

Step-by-Step Guide: Repairing Clear Coat Damage

Follow these detailed steps to effectively repair clear coat damage and restore your car’s finish.

-

Step 1: Prepare the Area

Begin by thoroughly cleaning the area around the clear coat damage. If the entire car hasn’t been washed recently, give it a full wash. Otherwise, focus on washing the panel you’ll be working on and any adjacent areas. This removes dirt, grime, and contaminants that could interfere with the repair process.

Once the area is clean and dry, use masking tape to carefully outline the repair area. Protect any adjacent panels that you won’t be respraying. Ensure the tape goes slightly inside the panel gap to prevent a hard line, but avoid letting it touch the panel you are repairing to prevent accidentally peeling off the new clear coat when removing the tape later.

-

Step 2: Remove Peeling or Damaged Clear Coat

Using a fine automotive Scotch-Brite pad, gently rub the most damaged areas first. Apply light to medium pressure and focus on removing any loose, peeling flakes of clear coat. If the color coat is exposed, reduce pressure and concentrate on smoothing the edges of the damaged clear coat.

Alternatively, you can use fine-grit sandpaper, starting with 1500 grit. Adjust the grit depending on the hardness of the clear coat; for tougher clear coats, you might start with a slightly coarser grit and move to finer grits. The goal is to remove the damaged clear coat and create a smooth transition to the surrounding undamaged areas.

Avoid using razor blades or any hard tools that could scratch the color coat. Deep scratches will require more extensive repair work.

-

Step 3: Create Blend Zones

After removing the peeling clear coat and scuffing the immediate repair area, create a blend zone. This involves extending the scuffed area approximately 3-4 inches in all directions around the initial repair. Use the same Scotch-Brite pad or 2000-grit wet sandpaper with very light pressure to scuff this blend zone. This step is crucial for ensuring the new clear coat adheres properly and blends seamlessly with the old clear coat.

Aim for a gradual, tapered transition from the repaired area to the old clear coat. This feathered edge will make blending much easier and less noticeable in the final finish.

-

Step 4: Clean the Area Again

Rinse the entire area with water to remove sanding dust and debris. Then, thoroughly wipe down the repair and blend zone with isopropyl alcohol. This critical cleaning step ensures that all dust, grease, wax, and contaminants are removed, providing a clean surface for the new clear coat to adhere to. Wait until the surface is completely dry before proceeding to the next step.

-

Step 5: Mask for Spraying

Use masking sheets, plastic foil, old newspapers, or paper towels to protect any adjacent panels that you don’t want to accidentally spray. Proper masking is essential to prevent overspray and keep the repair area confined.

For the outer edges of the work area, use a technique called back masking. Tape a piece of paper so that it covers the work area and extends into the blend zone, leaving some of the scuffed area exposed. Then, fold the paper back to create a soft edge at the border of the work area. This soft edge helps to feather the new clear coat into the old, making the blend less noticeable and preventing a hard paint line.

-

Step 6: Apply Clear Coat

Before applying any clear coat, carefully read and understand the manufacturer’s instructions on your chosen automotive clear coat spray paint. Pay close attention to:

- Mixing Instructions: Some clear coats require mixing with a hardener. Follow the precise mixing ratios provided by the manufacturer.

- Number of Coats: Determine the recommended number of coats for optimal coverage and durability.

- Flash Time: Understand the flash time, which is the waiting period between coats. This allows solvents to evaporate and prevents runs or drips.

- Spray Distance: Maintain the correct distance between the spray nozzle and the surface, typically around 8-10 inches, as specified by the manufacturer.

- Spray Technique: Learn the recommended spray pattern and speed. Consistent, overlapping strokes are crucial for an even finish.

Once you are familiar with the instructions, shake the clear coat can thoroughly for several minutes to ensure proper mixing of components. If your clear coat requires a hardener, activate and mix it according to the instructions, then shake again. Put on a respirator or appropriate mask to protect yourself from fumes. Test the spray on a piece of cardboard or paper to ensure the nozzle is working correctly and to get a feel for the spray pattern.

Hold the nozzle about 8 inches from the work area and apply a light to medium coat using smooth, even strokes. Overlap each stroke by about 30-40% to ensure consistent coverage. Keep your hand moving at a steady pace and release the spray button at the end of each stroke. It’s better to apply thinner coats than heavy coats to avoid runs and drips.

Apply two to three coats, allowing the recommended flash time (usually around 10 minutes) between each coat. After applying the final coat, let the clear coat dry overnight in a well-ventilated area, ideally indoors or under cover to protect it from dust and moisture. Inspect the results the next morning.

-

Step 7: Blend and Polish

After the new clear coat has fully hardened, carefully remove the masking tape and paper, being cautious not to peel off the newly applied clear coat.

Examine the borders of the repaired area. You will likely notice a line where the new clear coat meets the old. To blend this transition, use 2000-grit wet sandpaper. Wet sand lightly, keeping the area lubricated with water. You can refine further with 3000-grit sandpaper, expanding the blend zone slightly outward to smooth the transition even more.

Finally, polish the blended area to restore the shine and seamlessly integrate the repair with the surrounding paint. Use a rotary polisher on a low-speed setting with a medium-cut polishing pad and compound. Polish in a direction away from the new clear coat to prevent lifting or peeling it. Hold the polisher at a slight angle so that the contact is mainly on the edge of the pad. Use minimal pressure and make individual passes, lifting and restarting from the repair area. Check your progress frequently and stop polishing when the transition is barely noticeable, even up close. Finish with a wax or sealant to protect the newly polished area.

Choose CleanTools for Your Automotive Care Needs

Maintaining your car’s clear coat is an ongoing effort. Regular cleaning to remove contaminants like bugs and bird droppings is essential to prevent damage. The Absorber is an excellent tool for effortless cleaning and drying, helping you keep your car in top condition. While you can’t entirely prevent clear coat breakdown from scratches and UV exposure, prompt attention to damage and using quality products for cleaning, repair, and polishing, like those from CleanTools, will ensure your car looks its best for years to come.