How to Fix Car Seat Stitching: A DIY Guide to Restore Your Car Interior

Car seat stitching can come undone for various reasons, from regular wear and tear to accidental damage. A tear in your car seat not only detracts from the overall aesthetics of your vehicle’s interior but can also worsen over time if left unattended. While professional upholstery services are an option, learning How To Fix Car Seat Stitching yourself can save you money and give you a satisfying DIY project. This guide will walk you through the process of repairing car seat stitching, ensuring a durable and visually appealing result.

Understanding Car Seat Stitching Damage

Before diving into the repair process, it’s important to understand the type of damage you’re dealing with. Car seat stitching typically fails due to:

- Wear and Tear: Friction from getting in and out of the car, especially on the driver’s seat, can weaken threads over time.

- Sun Exposure: UV rays can degrade the thread, making it brittle and prone to breaking.

- Stress and Strain: Excessive weight or sharp objects can put stress on the seams, causing them to split.

- Accidental Damage: Snagging on seat belt buckles or other objects can directly tear the stitching.

Identifying the cause can help you choose the best repair method and prevent future issues.

Tools and Materials You’ll Need

For a successful car seat stitching repair, gather these essential tools and materials:

- Sewing Kit for Upholstery: Specifically designed for thicker materials, these kits usually include heavy-duty needles and strong threads.

- Curved Upholstery Needles: These needles are particularly helpful for working in tight spaces and following existing stitch lines.

- Heavy-Duty Upholstery Thread: Choose a thread that matches the color and thickness of your existing car seat stitching. Nylon or polyester threads are durable and resistant to wear and tear.

- Seam Ripper or Small Scissors: To carefully remove any frayed or loose threads.

- Pins: To hold the fabric edges together before stitching.

- Pliers (Optional): Can be helpful for pulling the needle through thick materials.

- Leather or Vinyl Repair Kit (Optional): If your car seats are made of leather or vinyl, a repair kit can help reinforce the area and prevent further tearing, especially if the material itself is damaged near the stitching.

Step-by-Step Guide: How to Fix Car Seat Stitching

Follow these steps to effectively repair your car seat stitching:

Step 1: Assess the Damage and Clean the Area

Carefully examine the torn stitching. Determine how extensive the damage is and whether the fabric itself is also damaged. Clean the area around the tear using a mild fabric cleaner and a soft cloth. Remove any dirt, debris, or loose threads that might interfere with the repair.

Step 2: Prepare Your Needle and Thread

Cut a length of upholstery thread that is comfortably manageable for sewing, typically around 18-24 inches. Thread your curved upholstery needle and tie a secure knot at the end of the thread.

Step 3: Align and Pin the Seam

Carefully align the edges of the torn seam, mimicking the original stitching line as closely as possible. Use pins to hold the fabric edges together securely. Ensure the edges are butted together neatly to avoid gaps in the repair.

Step 4: Begin Stitching

Starting from the backside of the fabric (if accessible) or from an inconspicuous point along the seam, insert the needle through the fabric, following the path of the original stitch line. Use a saddle stitch or back stitch for a strong and durable repair.

-

Saddle Stitch: This is a traditional hand-sewing technique known for its strength. Bring the needle through both layers of fabric, then pass the second needle through the same holes in the opposite direction. This creates a lock stitch.

-

Back Stitch: Bring the needle up through the fabric, then insert it back down a short distance behind the point where it emerged. Bring the needle up again a short distance in front of the first stitch, overlapping the previous stitch. This creates a solid, continuous line of stitching.

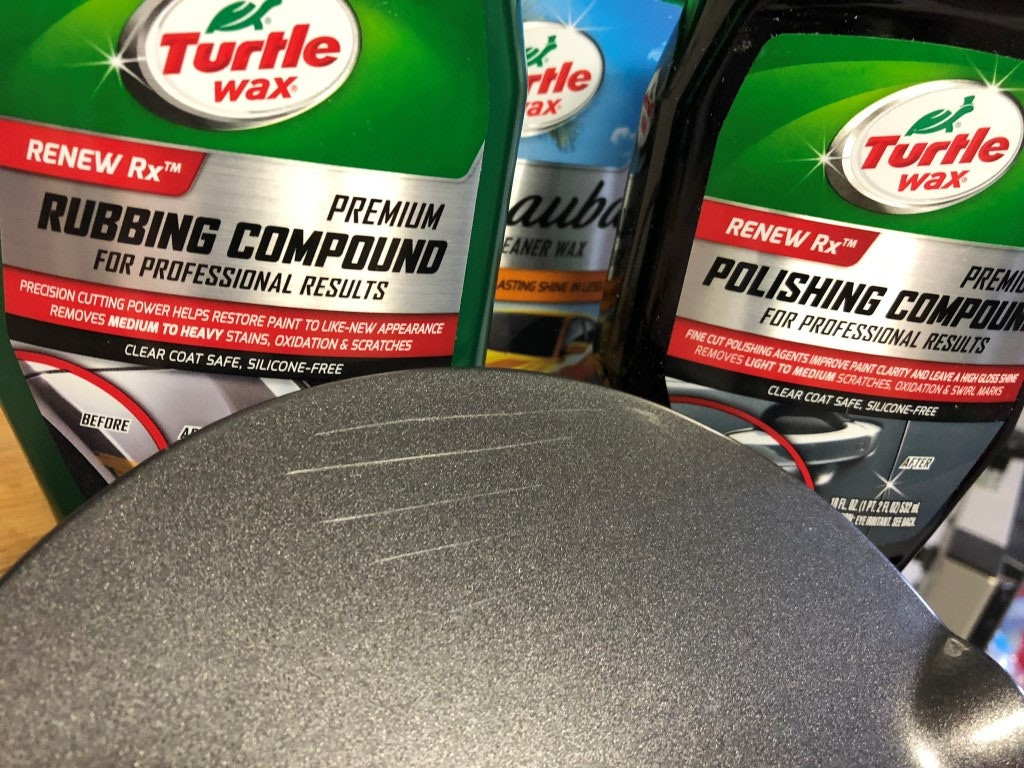

Image: An example of attempting to use glue to fix car seat stitching, highlighting why stitching is a more effective and professional approach.

Avoid using glue as a primary repair method for car seat stitching. As illustrated in the image above, glue can harden and become inflexible, potentially making future repairs more difficult and not providing a long-lasting solution. Stitching offers a more flexible and durable repair that maintains the integrity of the seat upholstery.

Step 5: Continue Stitching Along the Seam

Continue stitching along the entire length of the torn seam, maintaining consistent stitch spacing and tension. If you are using a curved needle, its shape will help you follow the curve of the seat and reach into tighter spots. Remove pins as you stitch, ensuring the seam remains aligned.

Image: An unsuccessful attempt to use wire for car seat stitching, demonstrating the need for proper needles and thread.

Using wire or overly rigid materials (as seen in the image above) is not recommended. Upholstery needles and thread are specifically designed to work with fabric and provide the necessary flexibility and strength for car seat repairs.

Step 6: Secure and Finish the Stitch

Once you reach the end of the tear, secure the stitching by making a few back stitches or tying a secure knot on the backside of the fabric. Trim any excess thread with scissors.

Image: Pins are essential for aligning the fabric edges and holding them in place before and during the stitching process, ensuring a neat seam.

Step 7: Inspect and Test the Repair

Carefully inspect your repair. Ensure the stitching is secure and the seam is aligned smoothly. Gently test the repaired area to ensure the stitches hold firm and the tear is effectively closed.

Image: Using a needle as a lever can be helpful for manipulating fabric edges into alignment, but careful stitching is crucial for a lasting repair.

While tools can assist in alignment (as shown above), the primary strength of the repair comes from the quality of the stitching itself. Focus on creating strong, even stitches along the original seam line.

Image: Pins are used to temporarily hold the fabric together, guiding the stitching process and ensuring proper alignment of the repaired seam.

Step 8: Final Touches (Optional)

For leather or vinyl seats, you might consider applying a leather or vinyl conditioner to the repaired area to help blend the repair and maintain the material’s suppleness.

Image: Hardened glue residue on car seat stitching demonstrates the limitations of glue as a repair solution and the importance of proper stitching techniques.

Avoid leaving glue residue or hardened areas on the stitching (as shown above), as this can be uncomfortable and visually unappealing. Proper stitching should result in a clean and flexible repair.

Tips for Preventing Future Stitching Problems

- Regular Cleaning: Clean your car seats regularly to remove dirt and grime that can weaken threads.

- UV Protection: Use car window tints or seat covers to minimize sun exposure.

- Gentle Use: Avoid placing excessive weight or sharp objects directly on the seams.

- Prompt Repair: Address small tears or loose threads promptly to prevent them from worsening.

Conclusion

Learning how to fix car seat stitching is a valuable skill for any car owner. By following these steps and using the right tools and techniques, you can effectively repair torn seams, restore the look of your car interior, and prevent further damage. While DIY repair can be satisfying, for extensive damage or if you’re uncomfortable with upholstery work, seeking professional help from an upholstery specialist is always a reliable option.