How to Fix a Car Horn: Troubleshooting and Repair Guide

You might not think about your car horn often, but it’s a crucial safety feature. It’s there to alert other drivers and pedestrians, preventing accidents in various situations. However, car horns can fail, leaving you without this important warning device. Typically located near the front grill, horns are exposed to harsh road conditions, including rain, dirt, and corrosive road salt. This exposure can lead to internal damage, often silencing the horn unexpectedly. Fortunately, diagnosing and fixing a car horn problem is often straightforward and can be done at home. This guide will walk you through the steps on How To Fix A Horn On A Car, from simple checks to more involved troubleshooting.

Common Causes of Car Horn Failure

Several factors can cause your car horn to stop working. Understanding these common issues is the first step in effective troubleshooting:

- Corrosion: Exposure to moisture and road salt can corrode the horn’s electrical connections, preventing proper function.

- Faulty Horn Switch: The switch in your steering wheel that activates the horn can wear out or malfunction over time.

- Clock Spring Issues: The clock spring is a rotary electrical connector in the steering column that allows the steering wheel to turn while maintaining electrical connections to components like the horn and airbag. A broken clock spring can interrupt the horn circuit.

- Bad Horn Relay: The horn relay is an electrical switch that controls power to the horn. A faulty relay can prevent the horn from receiving power.

- Wiring Problems: Damaged, broken, or shorted wires in the horn circuit can disrupt the flow of electricity, causing the horn to fail.

Step-by-Step Guide: How to Fix a Car Horn

Follow these steps to diagnose and repair your car horn.

1. Initial Inspection: Check for Corrosion

The first and easiest step in how to fix a horn on a car is a visual inspection. Car horns are commonly mounted in front of the radiator, behind the grille, making them vulnerable to road spray and debris.

Open your car’s hood and locate the horn(s). They usually look like small, trumpet-shaped devices or round discs. Carefully examine the wiring connections to the horn. Look for:

- Loose connections: Ensure the wires are firmly attached to the horn terminals.

- Corrosion: Check for white or green powdery buildup on the terminals and wire connectors.

If you find corrosion, disconnect the wires. Use a wire brush or terminal cleaner to thoroughly clean the lugs and terminal contacts. Reconnect the wires tightly and try honking the horn. If you hear a clicking sound from the horn area, or still no sound at all, proceed to check the fuse.

Inspecting car horn wiring connections for corrosion, a step in how to fix a horn on a car.

Inspecting car horn wiring connections for corrosion, a step in how to fix a horn on a car.

2. Test the Fuse

If cleaning the connections didn’t solve the problem, the next step in how to fix a horn on a car is to check the fuse. A blown fuse is a common cause of a non-working horn.

Locate your car’s fuse box. It’s usually under the dashboard, in the engine compartment, or sometimes on the side of the dashboard (check your owner’s manual for the exact location). Once you’ve found the fuse box, consult the owner’s manual to identify the fuse specifically for the horn. The manual will have a fuse box diagram indicating each fuse’s purpose.

- Inspect the Fuse: Carefully remove the horn fuse. Hold it up to the light and look for a broken wire inside the fuse. A blown fuse will have a melted or broken filament.

- Replace the Fuse: If the fuse is blown, replace it with a new fuse of the exact same amperage rating. Do not use a fuse with a higher rating.

- Test Again: After replacing the fuse, try the horn. If it works, the problem is solved.

If the fuse is not blown, or if the horn still doesn’t work after replacing a blown fuse, you can perform a direct power test to the horn using a fused jumper wire.

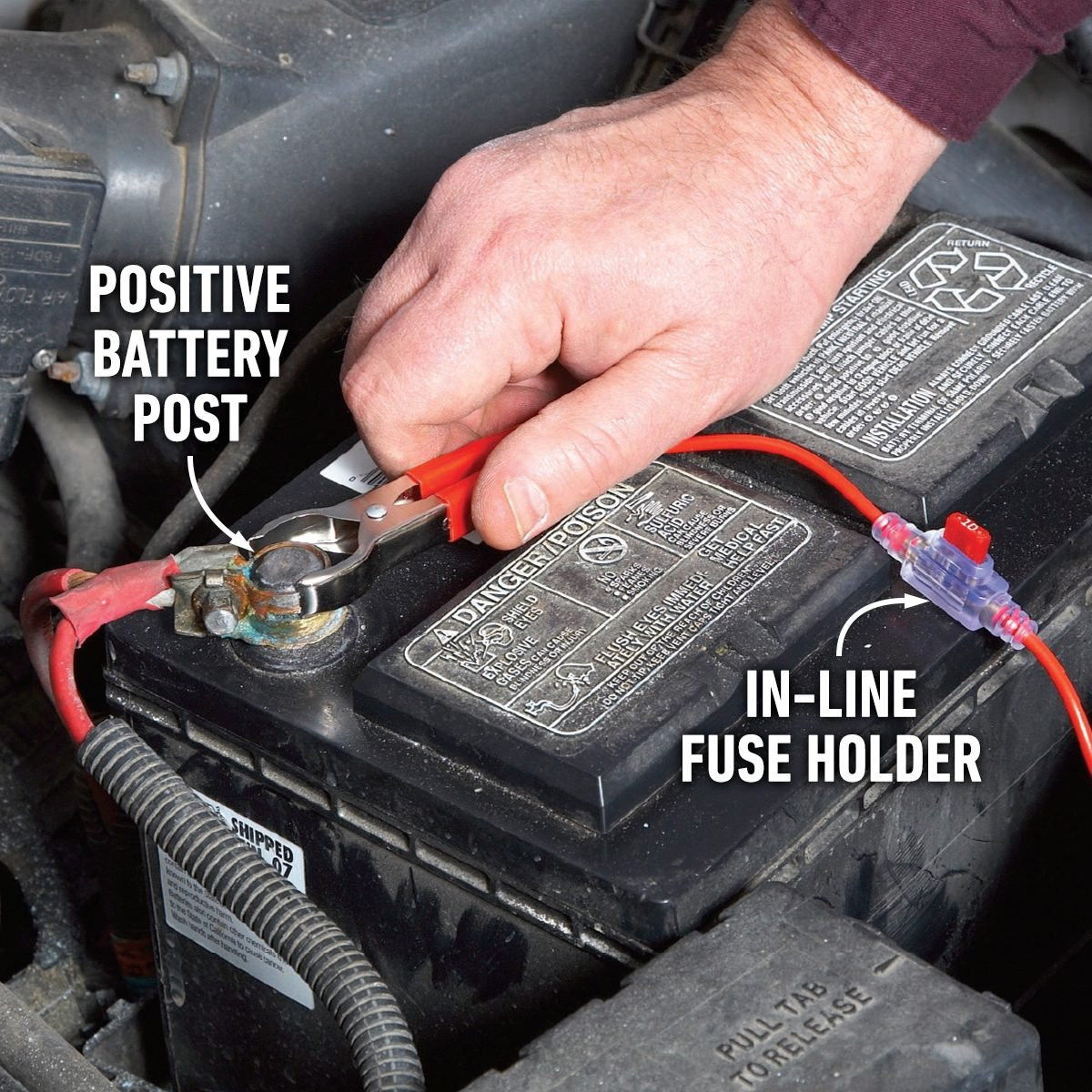

- Fused Jumper Test: A fused jumper wire is a simple tool to safely apply power directly to a component. You can make one using wire, battery clips, and an inline fuse holder with a fuse (around 10-15 amp).

- Connect the Jumper: Disconnect the wires from the horn terminals. Connect one end of your fused jumper wire to the positive terminal of the horn and the other end to the positive terminal of the car battery. Connect the other battery clip to the negative terminal of the car battery and touch the other end to the negative terminal on the horn.

- Listen for a Sound: If the horn works when powered directly, it indicates the horn itself is functional, and the issue lies upstream in the wiring, relay, or switch. If the horn only makes a clicking sound when directly powered, it might indicate a poor ground connection or internal horn damage requiring replacement.

- Check Ground: If you hear clicking, inspect and clean the horn’s ground connection point to the car’s chassis. Corrosion here can also cause issues. Re-test the horn with the fused jumper after cleaning the ground. If it still just clicks, the horn likely needs to be replaced.

Using a fused jumper wire to directly power a car horn to diagnose horn failure, part of car horn troubleshooting.

Using a fused jumper wire to directly power a car horn to diagnose horn failure, part of car horn troubleshooting.

3. Check the Relay

If the fuse is good and the horn works when powered directly with a fused jumper, the problem is likely further upstream in the electrical circuit, potentially in the horn relay. The relay is a switch that is activated by the horn button in your steering wheel to send power to the horn.

- Locate the Relay: Refer to your owner’s manual to find the location of the horn relay in the fuse box (it might be in the same fuse box or a separate relay box).

- Relay Swap Test: Relays are often the same type for different functions in your car (like headlights or wipers). Identify another relay of the same type in the fuse box (check the diagram). Temporarily swap the horn relay with this known good relay.

- Test the Horn Again: After swapping the relays, test the horn. If the horn now works, the original horn relay was faulty and needs to be replaced. You can purchase a new relay at any auto parts store.

- If Relay Swap Doesn’t Work: If swapping the relay doesn’t fix the horn, the problem may be a faulty horn switch in the steering wheel, a clock spring issue, or a broken wire in the steering column or elsewhere in the horn circuit. Diagnosing these issues can be more complex and may require specialized tools and knowledge.

Conclusion

Troubleshooting a car horn problem involves a systematic approach. Starting with simple checks like inspecting for corrosion and testing the fuse can often resolve the issue. If these steps don’t fix the problem, checking the relay and direct power testing can help narrow down the cause. If you’ve gone through these steps on how to fix a horn on a car and are still experiencing issues, it’s recommended to consult a qualified mechanic. They will have the expertise and tools to diagnose more complex electrical problems and ensure your car horn is functioning correctly for your safety.