How to Fix a Damaged Car: A DIY Guide to Harmonic Balancer Replacement

When your car is acting up, tackling repairs yourself can save money and be incredibly rewarding. One common issue that DIY mechanics might encounter is a damaged harmonic balancer. This crucial component is responsible for driving your car’s belts and keeping engine vibrations in check. Ignoring a damaged balancer can lead to more serious engine problems down the road. In this guide, we’ll walk through the process of replacing a harmonic balancer, drawing on real-world experience to help you avoid common pitfalls and get the job done right.

Understanding the Harmonic Balancer and Why Replacement Matters

The harmonic balancer, also known as a crankshaft pulley, is more than just a simple pulley. It’s designed to dampen torsional vibrations from the engine’s crankshaft. These vibrations, if left unchecked, can cause significant wear and tear on engine components. A failing harmonic balancer can exhibit symptoms like engine vibration, belt noise, or even visible damage to the pulley itself. Replacing it promptly ensures the longevity and smooth operation of your engine.

Step-by-Step Harmonic Balancer Removal

Before you start, safety first! Disconnect your car battery and ensure the engine is cool. You’ll need a harmonic balancer puller tool for this job – attempting to pry it off can cause damage.

-

Access the Balancer: Locate the harmonic balancer at the front of your engine. You may need to remove belts and accessory components to gain clear access.

-

Remove the Center Bolt: Using a socket wrench, remove the center bolt securing the harmonic balancer to the crankshaft. This bolt can be quite tight.

-

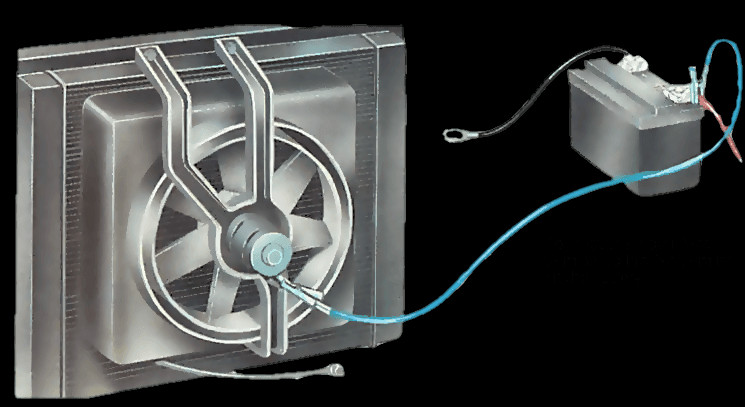

Attach the Puller Tool: Thread the puller tool bolts into the designated holes on the harmonic balancer. Position the puller’s center screw to press against the crankshaft.

-

Remove the Balancer: Slowly and steadily tighten the puller’s center screw. This will apply even pressure and pull the balancer off the crankshaft. Be patient and ensure the puller is aligned correctly.

Common Mistakes and How to Avoid Them

During this repair, one common mistake to avoid is using an inappropriate object to push against the crankshaft when using the puller. In one instance, a socket extension was used, which unfortunately became jammed in the crankshaft bolt hole. This highlights the importance of using the correct tools and anticipating potential problems.

What NOT to do:

- Don’t use a socket extension or similar soft metal object directly against the crankshaft. The force can cause it to become lodged or damage the crankshaft opening.

- Instead, use a hard, blunt object like the butt end of a drill bit or the correct adapter for your puller tool. This will provide a solid point of contact without risking damage or jamming.

If you encounter a stuck object like a jammed socket extension, persistence and careful problem-solving are key. In the example mentioned, a breaker bar was used to carefully wiggle and dislodge the stuck extension.

Installing the New Harmonic Balancer

Installing the new harmonic balancer correctly is just as crucial as removing the old one. Avoid hammering directly on the balancer as this can damage it or, more seriously, damage the engine’s crankshaft bearings.

-

Inspect for Damage: Before installation, inspect the crankshaft snout for any damage or burrs. Clean the surface to ensure a smooth fit.

-

Gentle Installation: The recommended method is to gently tap the new balancer onto the crankshaft using a rubber mallet. Work your way around the balancer, applying even pressure.

-

Use the Center Bolt: Once the balancer is partially seated, you should be able to thread the center bolt by hand. Use a ratchet to tighten the bolt, which will draw the balancer fully onto the crankshaft. Refer to your car’s service manual for the correct torque specification.

Tip: If the bolt feels difficult to thread, double-check the balancer alignment and ensure you are not cross-threading the bolt. If necessary, use a thread tap to clean up the threads in the crankshaft bolt hole.

-

Final Steps: Reinstall the belts and any accessory components you removed. Reconnect the car battery. Start your engine and check for smooth operation and belt alignment.

Proactive Maintenance: Checking Belts and Pulleys

While you have the front of your engine accessible, it’s wise to inspect and potentially replace other related components. Idler pulleys and belts wear out over time. Replacing them now can save you time and trouble later. If an idler pulley for the air conditioner belt is showing signs of wear (noise, wobble), replace it. Consider replacing all belts and pulleys if they are old or show signs of cracking or damage.

Conclusion: DIY Car Repair and Learning from Experience

Replacing a harmonic balancer is a manageable DIY task with the right tools and approach. The key takeaway is to proceed methodically, avoid forcing parts, and learn from any mistakes encountered along the way. Every repair job is a learning opportunity, enhancing your skills and confidence in car maintenance. Remember to always prioritize safety and consult your vehicle’s repair manual for specific instructions and torque specifications. While DIY repairs can be empowering, don’t hesitate to seek professional help if you encounter challenges beyond your comfort level.