How to Fix a Cracked Car Bumper: A Comprehensive Guide for Auto Repair Professionals

A cracked car bumper is more than just an eyesore; it can compromise the structural integrity of the vehicle if ignored. Whether caused by a minor parking mishap, a collision, or general wear and tear, bumper damage is a common issue that auto repair shops frequently encounter. Advising customers on the best course of action, whether repair or replacement, is crucial for ensuring their vehicles are safe and aesthetically pleasing once more.

This article serves as a comprehensive guide on How To Fix A Crack In Car Bumper, detailing when repair is feasible and when replacement is necessary. We will delve into the step-by-step process of repairing a cracked bumper, covering everything from structural fixes to paintwork and finishing, empowering you to refine your skills in this essential area of auto body repair.

Repair or Replace? Assessing Cracked Bumpers in Automotive Plastic Repair

The question of whether to repair or replace a cracked bumper is a common one in automotive plastic repairs. The good news is that a cracked bumper doesn’t automatically necessitate replacement. With the increasing use of plastics in modern vehicle construction, automotive plastic repair techniques have become increasingly sophisticated and commonplace for collision repairs. For auto body shops, this means that repair should always be the initial consideration when a customer presents a vehicle with bumper damage.

However, certain situations do warrant a full bumper replacement. Some vehicle manufacturers explicitly advise against repairing bumpers on their models, requiring replacement instead. Bumpers with extensive damage, multiple cracks, or damage that has been left untreated for a prolonged period may also be beyond repair and require replacement. Therefore, a thorough assessment is paramount to determine the most appropriate course of action for each specific case.

For minor cracks or dents that are not too deep, plastic repairs can often be classified as SMART (Small to Medium Area Repair Technology) repairs. In these instances, localized repairs can be performed without removing the entire bumper, making it a significantly more cost-effective and time-efficient solution compared to a full bumper replacement.

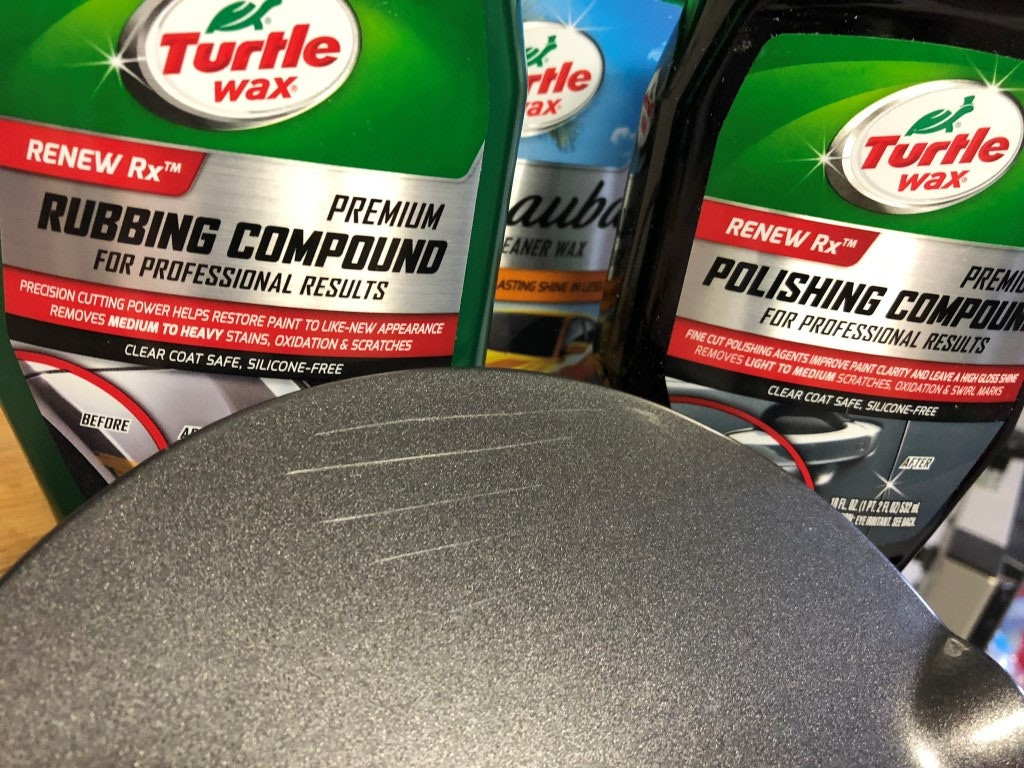

Close-up of a cracked car bumper, highlighting the damage.

Close-up of a cracked car bumper, highlighting the damage.

Repairing vs. Replacing: Key Assessment Questions for Bumper Damage

To effectively decide whether a cracked bumper can be repaired or needs to be replaced, your team needs to conduct a case-by-case evaluation of the damage. During this assessment, consider the following key questions to guide your decision-making process:

Feasibility of Repair

Begin by thoroughly examining the extent of the damage to ascertain if repair is even a viable option. This involves consulting the vehicle manufacturer’s guidelines to confirm if bumper repairs are permitted for that specific model, as some manufacturers mandate replacement. Furthermore, carefully evaluate the size, depth, and location of the crack. Extensive or deep cracks, especially those affecting critical structural points of the bumper, might compromise its integrity and rule out repair.

Safety Implications

Safety is paramount in all auto repairs, and bumper repair or replacement is no exception. If repair is chosen, critically assess whether the structural integrity of the bumper can be restored to its original safety standards. Bumpers are designed to absorb impact and protect vehicle occupants in minor collisions. If the repair compromises this structural integrity, it could pose a safety risk in future incidents.

Always prioritize replacement if explicitly recommended by the manufacturer’s guidelines. Replacement is also mandatory if the underlying support structure of the bumper is damaged or if repairs could potentially interfere with the vehicle’s safety systems, such as parking sensors or collision avoidance technology integrated into the bumper.

Efficiency and Cost-Effectiveness

For minor, isolated cracks, repair is generally the more efficient and cost-effective solution. However, extensive cracking or widespread damage can significantly increase repair time, potentially making replacement a more practical choice.

A qualified Vehicle Damage Assessor (VDA) should estimate the labor hours required for the bumper repair. This estimate should then be compared to the cost of a new bumper, including parts availability and delivery lead times. This comparative analysis will enable your team to determine the most cost-effective and efficient solution for both your shop and the customer.

Customer-Centric Approach

Ultimately, the decision should prioritize the customer’s best interests. If a repair offers only a temporary or substandard fix for a significant underlying problem, it is your professional responsibility to advise the customer accordingly. For minor cosmetic damage, a SMART bumper repair might be ideal for customers seeking a quick and economical solution. Conversely, more substantial cracks, dents, or scratches may necessitate either a more extensive repair or a full replacement to ensure long-term durability and safety. Communicate transparently with the customer, discuss their options, consider their desired turnaround time, and provide clear explanations of the pros and cons of each approach.

Close-up of a car's front bumper, showing minor scratches.

Close-up of a car's front bumper, showing minor scratches.

Step-by-Step Guide: How to Repair a Cracked Bumper for a Professional Finish

Once you’ve determined that repairing the cracked bumper is the appropriate course of action, you can proceed with the repair process. The following step-by-step guide outlines the procedure to achieve a flawless finish for your customers, while ensuring efficiency and minimizing complications. While removing the bumper might be necessary in some cases, it should ideally be considered as a last resort.

1. Thorough Damage Assessment

Begin with a comprehensive assessment of the damage. Ideally, removing the bumper will provide the clearest view of the crack’s extent, allowing you to accurately gauge its size, depth, and identify any hidden or secondary cracks. This detailed examination will solidify your decision on whether repair or replacement is truly the best option.

2. Masking Adjacent Areas

To protect surrounding panels and areas from accidental damage during drilling, sanding, and painting, meticulous masking is crucial, especially if the bumper remains on the vehicle. We recommend using a high-quality automotive masking tape, such as JTAPE Premium Cloth Protection Tape, applied along the edges adjacent to the bumper. This robust automotive cloth protection tape will effectively prevent unwanted scratches, overspray, and ensure a clean, professional finish.

Technician carefully repairing a car bumper in a workshop.

Technician carefully repairing a car bumper in a workshop.

3. Drilling to Prevent Crack Propagation

To prevent the crack from spreading further during the repair process, drill two small holes, approximately 6mm in diameter, one at each end of the damaged area. These holes act as stress relief points, effectively stopping the crack from extending beyond the repair zone.

4. Creating a Bonding Groove: Carving and Grinding

The next critical step is to maximize the bonding surface area for the repair materials. This is achieved by carving a V-shaped groove along the crack line on the front-facing edge of the bumper. Using a rotary tool or grinder and a sharp knife, carefully remove plastic residue and create the V-groove pattern. This groove will provide a larger and more textured surface for the epoxy and body filler to adhere to, resulting in a stronger and more durable repair.

5. Sanding the Damaged Area (Front and Back)

Once the V-groove is carved, thoroughly sand the area on both the front and back of the bumper using medium-grit sandpaper. Sanding serves multiple purposes: it removes loose debris and minor imperfections, and, crucially, it creates micro-abrasions on the plastic surface. These micro-abrasions significantly enhance the effectiveness of the plastic adhesion promoter and improve paint adhesion, ensuring a long-lasting finish.

6. Applying Plastic Adhesion Promoter (Front and Back)

Proper surface preparation is paramount for successful plastic repair. Apply a plastic adhesion promoter spray to both the front and back of the sanded area. This promoter chemically modifies the plastic surface, creating a stronger bond for the epoxy and body filler that will be applied subsequently. This step is essential for preventing delamination and ensuring the repair materials properly adhere to the bumper, contributing to a seamless and durable finish.

7. Epoxy Application on Both Sides

Apply automotive-grade epoxy to both sides of the prepared bumper crack. Begin with the back side, as this is less visible, and smooth the epoxy application using a spreader. Then, apply epoxy to the front side, ensuring it fills the V-groove and bonds the crack edges together. Allow ample drying time for the epoxy to fully cure according to the manufacturer’s instructions. The epoxy provides structural strength to the repair and creates a solid foundation for the body filler.

8. Surface Preparation and Sanding for Body Filler

After the epoxy has hardened completely, sand the repaired area again to create a smooth and even base for the body filler. Feather the edges of the repair area to blend them seamlessly with the surrounding bumper surface. Aim for a slight depression where the crack was, to accommodate the body filler and ensure a level final surface.

Hands meticulously cleaning a car bumper, preparing it for repair.

Hands meticulously cleaning a car bumper, preparing it for repair.

9. Body Filler Application

Apply a pre-mixed automotive body filler evenly over the prepared repair area. Carefully follow the contours and curves of the bumper during application, using a spreader to smooth the filler and achieve the desired shape. This step is crucial for restoring the bumper’s original profile and ensuring a professional-quality finish. Once the body filler is fully dry, lightly sand the area to prepare it for painting.

10. Painting and Finishing the Bumper

The final stage is painting the repaired plastic bumper to restore its original appearance. Employ high-quality foam masking tapes, such as JTAPE Foam Masking Tapes, to mask off the surrounding panels. Foam masking tape creates a soft edge, minimizing paint lines and ensuring a seamless blend between the new paintwork and the original finish.

With the adjacent areas properly masked, begin the painting process by applying an even coat of automotive primer. Allow the primer to dry completely before applying several thin coats of the vehicle’s base color, allowing each coat to dry before applying the next. Finish with a few coats of clear coat for protection and gloss. After the paint has fully cured, carefully remove the foam masking tape to reveal a perfectly blended, high-quality finish that will satisfy your customer.

For minor scuffs, scratches, and hairline cracks, bumper removal may not be necessary. However, for more extensive damage or if you suspect damage to the bumper’s backside or mounting points, removing the bumper is advisable for a thorough assessment and repair.

If bumper removal is required, safely lift the vehicle using a jack and locate the fasteners – typically pins, latches, and screws – securing the bumper to the car. These are commonly found within the wheel arches, near the bumper’s edges. Remove all fasteners, including any electrical connectors or additional screws holding the bumper in place.

It’s important to note that if a crack extends to the very edge of the bumper, replacement is generally the recommended best practice, as the structural integrity of the bumper is likely significantly weakened.

In conclusion, while bumper replacement is sometimes necessary, repairing a cracked bumper is often a viable, efficient, and cost-effective solution. The expertise of the body shop team in assessing the damage and executing proper repair techniques is paramount in delivering the best outcome for the customer.

For over two decades, JTAPE has been a leading provider of automotive masking solutions for repair and refinishing. Explore our blog for more expert tips and advice on automotive repair best practices.