How to Fix a Crack in Your Car Body: A Step-by-Step Guide

Cracks in your car body, while sometimes minor, can detract from your vehicle’s appearance and potentially lead to further damage if left unattended. Whether it’s a hairline fracture from a minor impact or a more noticeable split, addressing these cracks promptly is essential. This guide provides a detailed, step-by-step approach on how to fix a crack in your car body effectively, utilizing readily available tools and materials.

Assessing the Crack

Before you begin, it’s crucial to properly assess the crack. Examine the extent of the damage. Is it a superficial surface crack, or does it penetrate deeper into the car body material? For minor cracks, a simple adhesive solution can suffice. However, for more significant damage, reinforcement might be necessary to ensure a lasting repair. This guide focuses on repairing minor to moderate cracks, often encountered in non-structural areas of the car body, using liquid cement and wire reinforcement for added strength.

Preparing the Area for Repair

Cleanliness is paramount for a successful repair. Start by thoroughly cleaning the area around the crack. Use soap and water to remove any dirt, grease, or wax. For stubborn residues, isopropyl alcohol can be effective. Ensure the area is completely dry before proceeding. This clean surface will allow the adhesive to bond properly, ensuring a strong and durable repair.

Applying Liquid Cement

Liquid cement, known for its capillary action, is ideal for filling fine cracks. For hairline cracks, you may need to gently widen the gap slightly to allow the cement to penetrate effectively. Be extremely cautious when doing this, especially if the plastic is thin or weakened around the crack.

Apply a small amount of liquid cement along the crack line. The capillary action will draw the cement into the crack. If the crack is slightly wider, you can use a fine applicator or the tip of the cement tube to carefully apply the adhesive. It’s crucial to use a liquid cement specifically designed for plastics to ensure proper bonding and prevent damage to the car body material. Brands like Ambroid or Tenax are often recommended for their effectiveness in plastic modeling and repair, and are suitable for car body plastics.

Aligning and Curing the Repair

Once the liquid cement is applied, carefully align the cracked pieces if they have shifted. If you are fortunate and the body panels are not stressed or torqued, you might be able to let the pieces settle into their natural position for curing. However, if there’s any tension, you’ll need to secure the body in the correct alignment while the cement cures.

Use masking tape to hold the pieces firmly in place. Ensure the alignment is perfect before the cement sets. For more complex shapes, you might need to use clamps or weights to maintain the correct form. Allow ample curing time, typically a few hours, to ensure the liquid cement hardens completely and forms a strong bond. Refer to the manufacturer’s instructions for specific curing times.

Reinforcing the Crack for Durability

For added strength and to prevent the crack from reopening, especially in areas prone to stress or vibration, reinforcement is recommended. After the initial cement has cured, use a razor saw, a photo-etched saw blade, or a panel scriber to create a shallow channel or trough on the backside of the cracked area. This channel should run along the crack line and extend slightly beyond both ends of the crack to ensure robust reinforcement.

The trough needs to be wide and deep enough to accommodate a piece of metal wire and some superglue. A guitar string or a thin wire from a Christmas ornament hanger are excellent choices for reinforcement wire, as they are stiff yet thin enough to be easily workable. Cut a piece of wire slightly shorter than the trough. Apply superglue into the trough and carefully press the wire into place. Ensure the wire is fully embedded in the superglue and fills the trough. Avoid using excessive superglue, as it can interfere with the fit of other components, such as windshields or trim pieces. If you have a CA kicker (cyanoacrylate accelerator), use it to instantly cure the superglue, speeding up the process.

Final Finishing and Smoothing

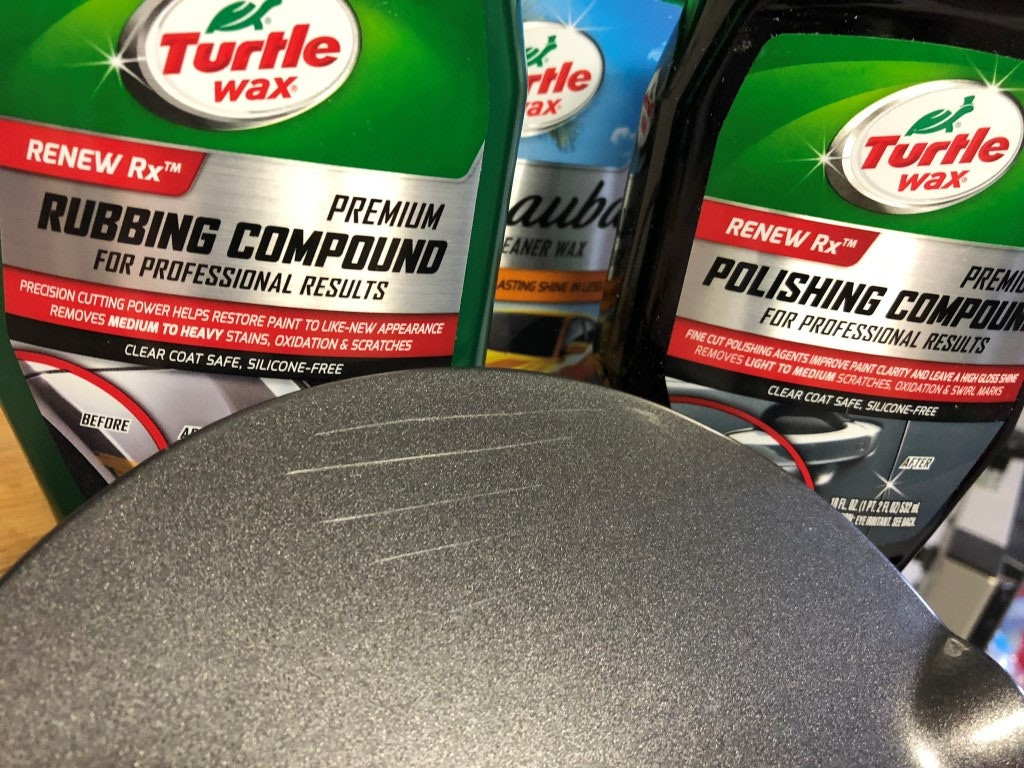

Once the superglue is fully cured, inspect the repaired area. If there are any lumps or bumps from the superglue or cement, gently sand them down using fine-grit sandpaper or a file. Start with a coarser grit and gradually move to finer grits for a smooth finish. Be careful not to sand away the surrounding paint if you are working on a painted car body. The goal is to create a seamless and even surface, making the repair virtually invisible.

Conclusion

By following these steps, you can effectively fix a crack in your car body, restoring its appearance and structural integrity. Remember, patience and careful execution are key to achieving a professional-looking and long-lasting repair. This method, combining liquid cement and wire reinforcement, provides a robust solution for minor to moderate car body cracks, ensuring your vehicle looks its best and is protected from further damage.