How to Fix a Broken Horn on a Car: Step-by-Step Troubleshooting Guide

It’s easy to take your car horn for granted, until it stops working. That urgent beep is crucial for safety, whether you need to alert another driver or simply express your impatience at a slow-changing traffic light. A malfunctioning horn can be more than just an annoyance; it’s a safety issue. Fortunately, diagnosing and fixing a broken car horn is often a straightforward process you can tackle yourself. This guide will walk you through the steps to troubleshoot and repair your car horn, saving you a trip to the mechanic.

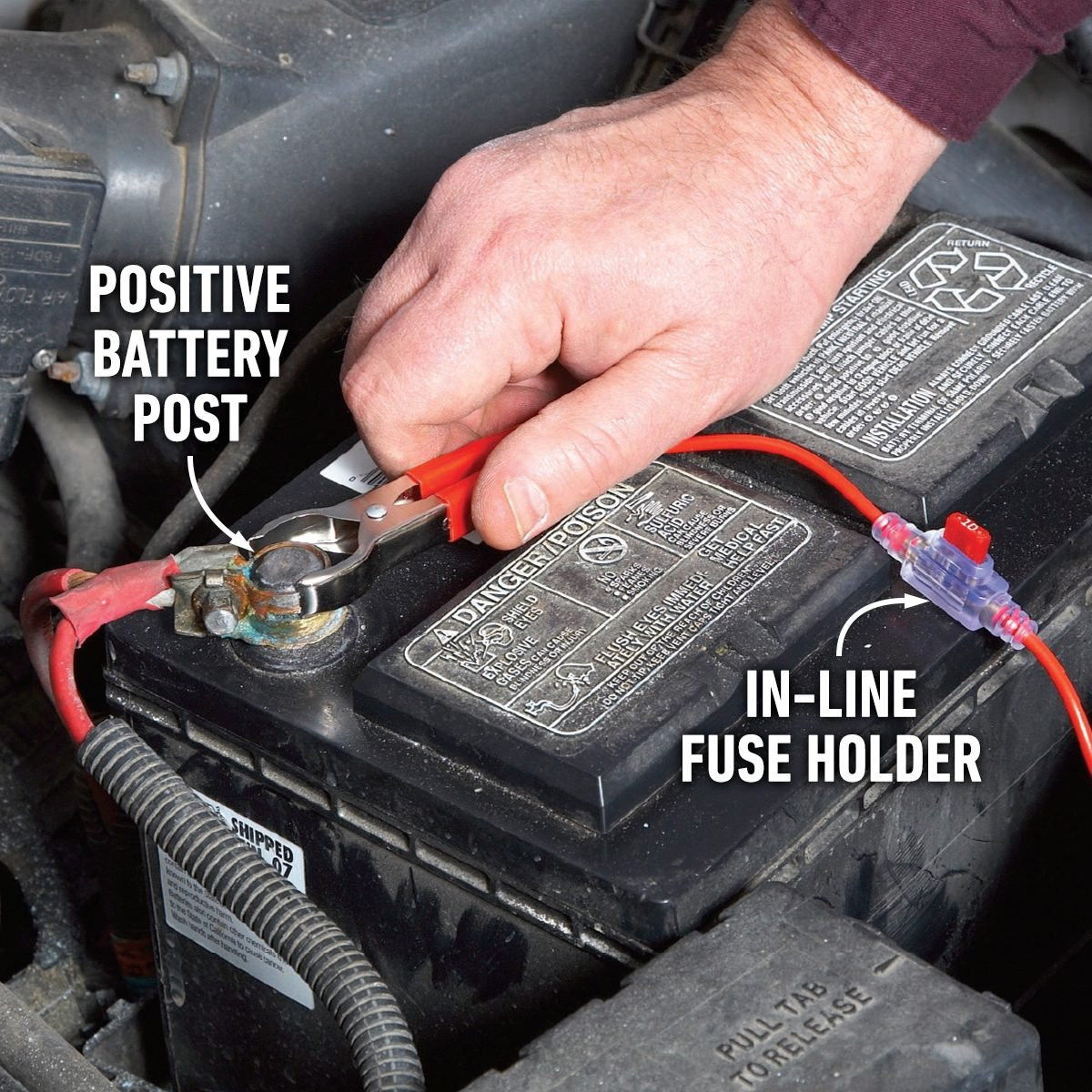

Check for Corrosion at the Horn Connections

Your car’s horn is typically located in a vulnerable spot, often behind the front grille where it’s exposed to the elements. Road spray, dirt, and especially corrosive road salt can take their toll over time. Before you assume a complex electrical problem, start with a simple visual inspection under the hood.

Begin by examining the wiring connections directly at the horn itself. Look closely for any signs of corrosion, loose connections, or damage to the wires. Make sure the connections are firmly attached. A good first step is to disconnect the wires, clean the metal terminals and connectors with a wire brush or terminal cleaner to remove any corrosion buildup, and then firmly reconnect them. After cleaning and reconnecting, test the horn again. Listen for any sound at all – even a clicking noise can provide clues. If you hear clicking or still no sound, the next step is to check the fuses.

Checking car horn electrical connections for corrosion

Checking car horn electrical connections for corrosion

Inspect the Horn Fuse

The next common culprit for a silent horn is a blown fuse. Locate your car’s fuse box, which is usually found under the dashboard, in the engine compartment, or sometimes on the side of the dashboard. Your owner’s manual is the best resource for pinpointing the exact location of the fuse box and the fuse specifically for the horn.

Open the fuse box and look for any fuses that appear to be blown – signs include a melted wire inside the fuse or a dark, charred appearance. If you see any blown fuses, it’s important to note if other circuits are also affected, as this could indicate a more significant electrical issue.

Once you’ve located the horn fuse, check if it’s blown. If it is, replace it with a fuse of the same amperage rating. If the fuse was blown, test the horn after replacement. If the new fuse blows immediately, or the horn still doesn’t work, proceed to the next troubleshooting step.

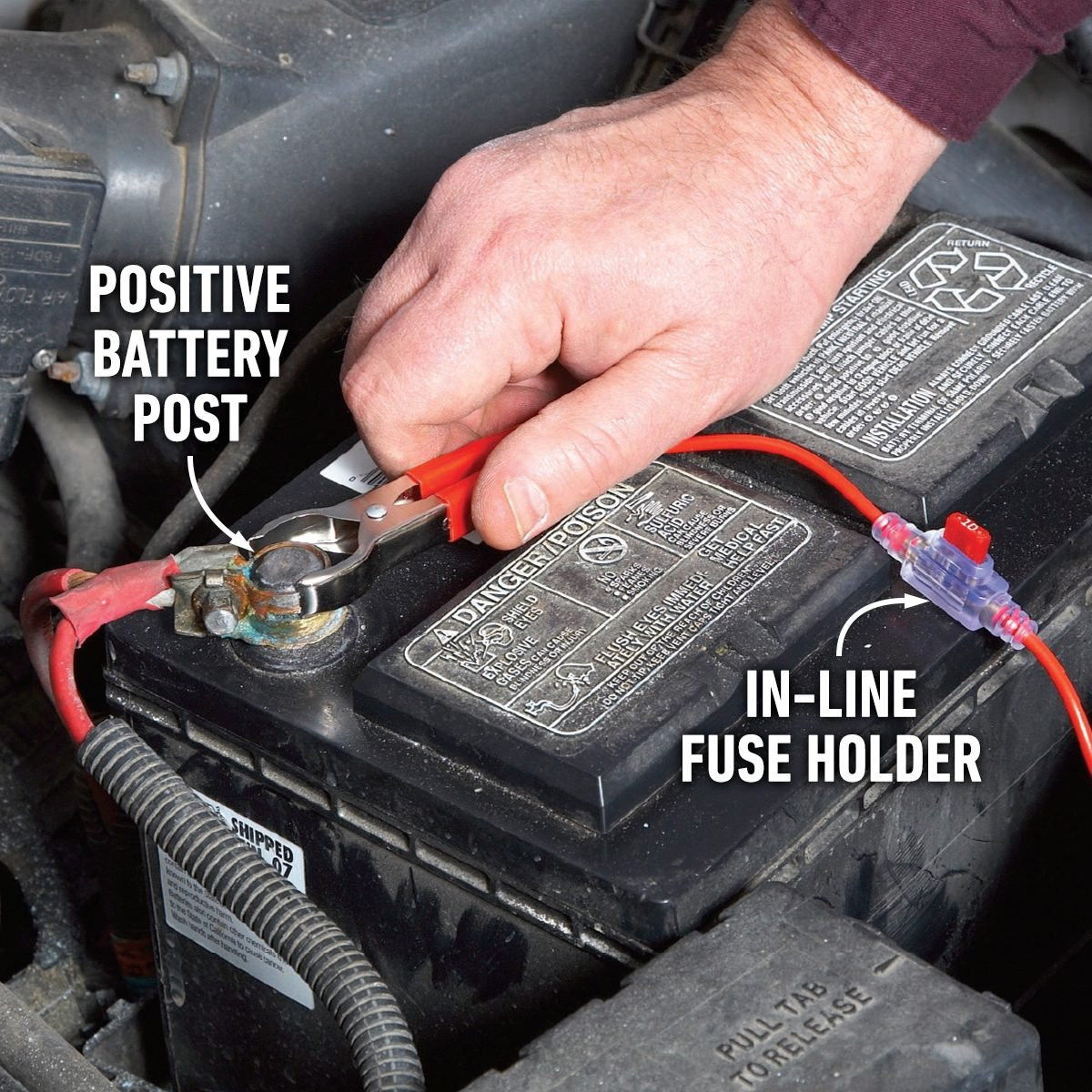

If the fuse is intact and doesn’t appear blown, the next step is to bypass the car’s wiring temporarily to test the horn directly. You can do this using a fused jumper wire. A simple fused jumper can be made with two battery clips, a length of wire, and an in-line fuse holder with a fuse. Connect one clip of your jumper directly to the positive terminal of the car battery and the other clip to the positive terminal on the horn itself. If the horn sounds when you do this, it means the horn itself is functional, and the problem lies upstream in the electrical circuit – possibly a poor ground connection, the relay, or the wiring.

If the horn only clicks when you use the fused jumper, a poor ground connection to the horn might be the issue. Locate the horn’s ground connection, usually a wire attached to the car’s chassis near the horn. Clean this ground connection thoroughly to remove any rust or corrosion that could be preventing a good electrical ground. After cleaning the ground, try powering the horn again with the fused jumper. If the horn still only clicks, it’s likely the horn itself is faulty and needs replacement.

Using a fused jumper wire to test a car horn directly

Using a fused jumper wire to test a car horn directly

Test the Horn Relay

If you’ve confirmed the fuse is good and the horn works when powered directly with a fused jumper, the issue is likely further upstream in the horn circuit. Before digging into tracing wires, a simple next step is to check the horn relay.

The horn relay is an electrical switch that controls the power to the horn. It’s typically located in the fuse box, often in the engine compartment. Refer to your owner’s manual to identify the location of the horn relay. Relays are often interchangeable, and a common troubleshooting technique is to swap the horn relay with another relay of the same type from a less critical system, such as the windshield wipers or headlights (ensure the relays are identical part numbers or specifications before swapping).

If swapping the relay resolves the problem and the horn now works, then the original relay was faulty and needs to be replaced. However, if swapping the relay makes no difference, and the horn still doesn’t function, the problem is likely more complex, potentially involving a broken wire, a faulty clock spring in the steering column, or a problem with the horn switch itself. At this point, if you are not comfortable with more in-depth electrical troubleshooting, it’s advisable to take your vehicle to a qualified mechanic to diagnose and repair the issue. A professional mechanic will have the tools and expertise to trace electrical faults and ensure your car horn is working reliably again.