How Do I Fix My Car Horn? A Step-by-Step Troubleshooting Guide

It’s something most drivers take for granted, until it stops working – your car horn. Suddenly, you realize how much you rely on that beep to navigate traffic, alert other drivers, or even just to express a little road frustration. If your car horn has gone silent, don’t panic. Often, the fix is simpler than you might think. This guide will walk you through the common causes of a car horn malfunction and provide step-by-step instructions on how to diagnose and potentially fix the problem yourself.

Common Causes of a Car Horn Not Working

Before you start tearing apart your dashboard, it’s helpful to understand the usual suspects behind a car horn failure. Several factors can contribute to your horn going silent, and identifying the most likely cause will streamline the repair process.

- Corrosion: Car horns are frequently located in exposed areas, often behind the front grille. This placement makes them vulnerable to the elements – rain, road salt, dirt, and grime. Over time, this exposure can lead to corrosion of the horn’s electrical connections, preventing it from functioning.

- Blown Fuse: Like many electrical components in your car, the horn is protected by a fuse. A power surge or a short circuit in the horn system can cause this fuse to blow, cutting off power to the horn.

- Faulty Relay: The horn circuit often includes a relay, which is an electrical switch that helps control the higher current needed for the horn. A failing relay can prevent power from reaching the horn, even if the fuse is intact.

- Steering Wheel Switch or Clock Spring Issues: When you press the horn button on your steering wheel, you’re activating a switch. If this switch is faulty, or if the clock spring (a spiral-wound ribbon cable that maintains electrical connections as the steering wheel turns) is damaged, the signal to activate the horn may not be transmitted.

- Wiring Problems: Less commonly, a broken, shorted, or damaged wire in the horn circuit can be the culprit. This could be anywhere along the wiring path from the fuse box to the horn itself.

Step-by-Step Guide to Fix Your Car Horn

Fixing your car horn can often be achieved with basic tools and a bit of patience. Follow these steps to troubleshoot and get your horn working again.

1. Check for Corrosion on the Horn

The first and easiest step is a visual inspection. Pop your car’s hood and locate the horn(s). They are typically found near the front grille area.

- Visually Inspect Connections: Examine the wires connected to the horn terminals. Look for any signs of corrosion – white or greenish deposits on the metal connectors. Ensure the connections are secure and tight.

- Clean Corroded Connections: If you see corrosion, disconnect the wires from the horn terminals. Use a wire brush or sandpaper to gently clean the terminals and the inside of the wire connectors to remove the corrosion. You can also use a specialized electrical contact cleaner spray.

- Reconnect and Test: After cleaning, reconnect the wires firmly to the horn terminals. Try pressing your car horn to see if it now works. If you hear clicking sounds from the horn area but no actual horn sound, it could indicate a grounding issue or a faulty horn unit. If there’s still no sound, move to the next step.

Inspecting car horn wire connections for corrosion as part of car horn troubleshooting.

Inspecting car horn wire connections for corrosion as part of car horn troubleshooting.

2. Inspect the Fuse

If cleaning the connections didn’t solve the problem, the next most common issue is a blown fuse.

- Locate the Fuse Box: Consult your car’s owner’s manual to find the location of the fuse box(es). There are usually fuse boxes under the dashboard and sometimes in the engine compartment.

- Identify the Horn Fuse: Refer to the fuse box diagram (usually printed on the fuse box cover or in your owner’s manual) to locate the fuse specifically for the horn.

- Check the Fuse: Visually inspect the fuse. A blown fuse will often have a broken wire inside or signs of melting or charring. You can also use a fuse tester to check for continuity – a blown fuse will show no continuity.

- Replace the Fuse: If the fuse is blown, replace it with a new fuse of the same amperage rating. Never use a fuse with a higher amperage rating, as this can damage the electrical system.

- Test the Horn: After replacing the fuse, test the horn again. If it works, the blown fuse was the problem. If the new fuse blows immediately, or the horn still doesn’t work, there’s likely a more serious issue, such as a short circuit or a faulty horn unit itself.

3. Test the Relay

If the fuse is good, the next component to check is the horn relay.

- Locate the Horn Relay: Again, your owner’s manual will be your best guide to find the horn relay, which is usually located in the fuse box, often in the engine compartment.

- Swap the Relay (if possible): Relays are often interchangeable if you have another relay of the same type in the fuse box (for example, for the headlights or windshield wipers). Note down the original position of each relay before swapping. Swap the horn relay with a known good relay of the same type.

- Test the Horn: After swapping the relays, test the horn. If the horn now works, the original relay was faulty and needs to be replaced. You can purchase a new relay at any auto parts store.

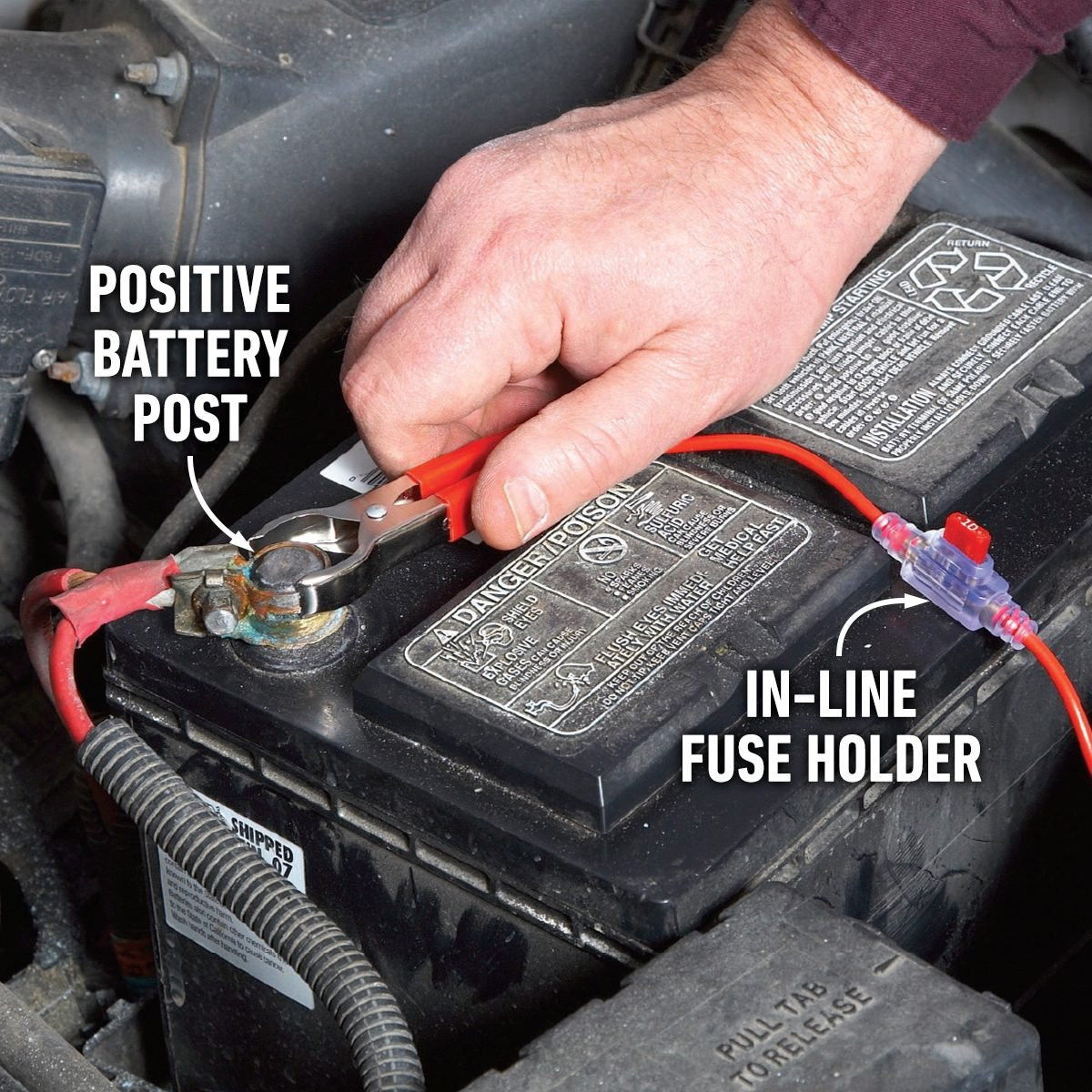

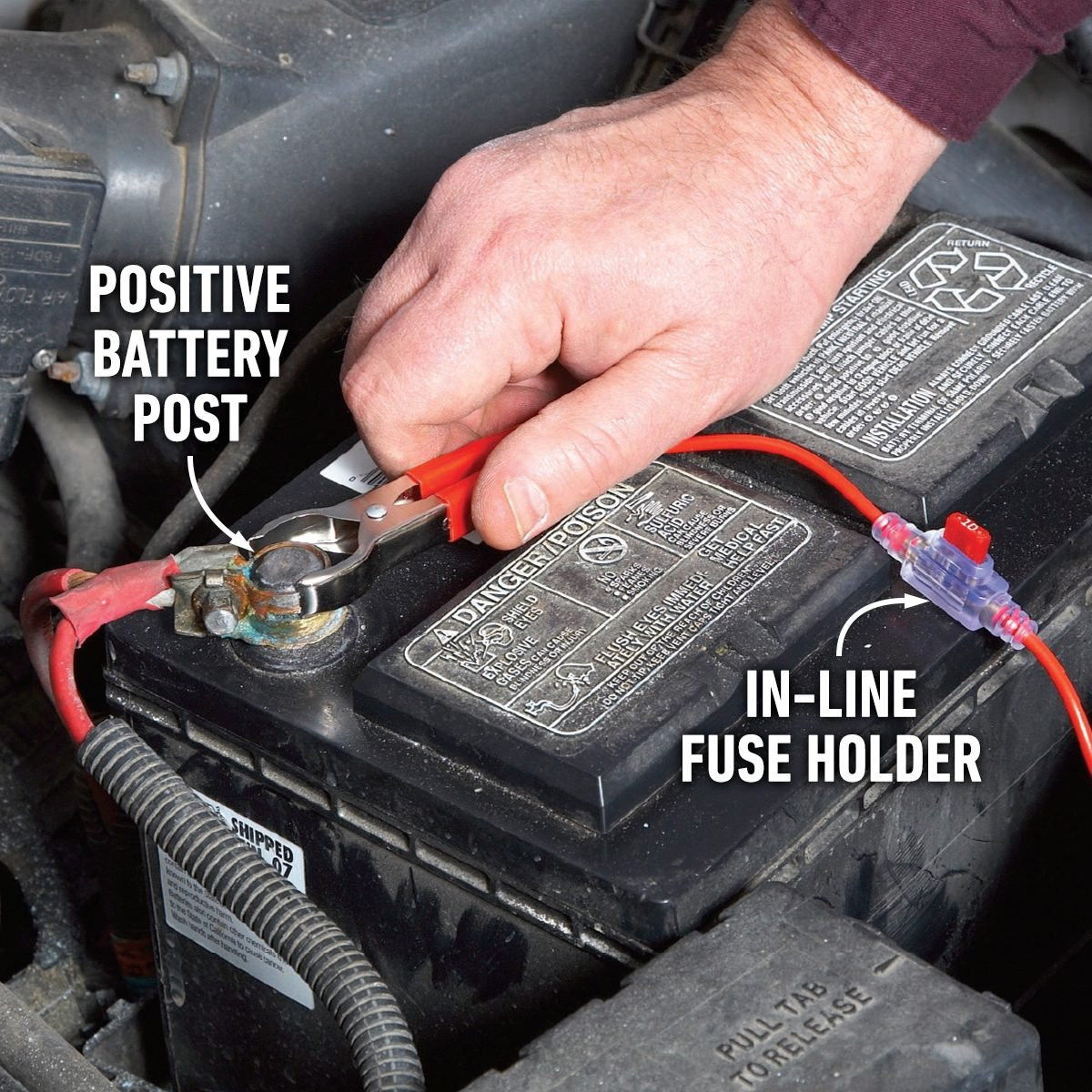

- Jump Power to the Horn (Advanced Test): If swapping the relay doesn’t work, or if you want to further isolate the problem, you can try directly powering the horn using a fused jumper wire. This requires caution and some basic electrical knowledge.

- Create a Fused Jumper: Use a wire with alligator clips at both ends and an inline fuse holder with a fuse (same amperage as the horn fuse) in the middle.

- Connect Jumper: Disconnect the wires from the horn terminals. Connect one clip of your fused jumper wire directly to the positive (+) terminal of the car battery and the other clip to the positive terminal on the horn itself. Connect the horn’s negative terminal to a good ground point on the car’s chassis.

- Observe the Horn: If the horn works when powered directly, this indicates that the horn unit itself is functional, and the problem lies upstream in the wiring, fuse, relay, or switch. If the horn still doesn’t work when powered directly, the horn unit itself is likely faulty and needs replacement.

Using a fused jumper wire to directly power a car horn to diagnose a faulty circuit.

Using a fused jumper wire to directly power a car horn to diagnose a faulty circuit.

4. When to See a Professional

If you’ve checked the connections, fuse, and relay, and your car horn is still not working, the problem might be more complex, such as a faulty steering wheel switch, a damaged clock spring, or a wiring issue deeper in the system. Diagnosing and repairing these issues can require specialized tools and knowledge.

At this point, it’s advisable to take your vehicle to a qualified and trusted mechanic. They will have the expertise and equipment to accurately diagnose the problem and perform the necessary repairs to get your horn working reliably again.

Conclusion

A working car horn is essential for safe driving. By following these troubleshooting steps, you can often diagnose and fix a car horn problem yourself, saving time and money. Start with the simple checks – corrosion and fuses – and progress systematically through the relay and direct power tests. If you reach a point where you’re uncomfortable or unsure, don’t hesitate to seek professional help. Keeping your horn in good working order ensures you can communicate effectively on the road and drive with greater safety and confidence.