1. Understanding the ESP System in Your Mercedes W203

The Electronic Stability Program (ESP) in your Mercedes W203 is a vital safety system designed to prevent skidding and loss of control. The ESP system integrates several sub-systems, including ABS (Anti-lock Braking System), ASR (Acceleration Ski...

1. Understanding the ESP System in Your Mercedes W203

The Electronic Stability Program (ESP) in your Mercedes W203 is a vital safety system designed to prevent skidding and loss of control. The ESP system integrates several sub-systems, including ABS (Anti-lock Braking System), ASR (Acceleration Skid Control), and BAS (Brake Assist System). The ESP module monitors wheel speed, steering angle, and yaw rate to detect deviations from the intended driving path. When a loss of control is imminent, ESP selectively applies brakes to individual wheels and adjusts engine power to help the driver maintain control. Understanding this interplay is the first step in addressing an ESP malfunction.

Here’s a breakdown of the critical components:

- Wheel Speed Sensors: These sensors monitor the speed of each wheel and provide data to the ESP module.

- Steering Angle Sensor: This sensor detects the angle of the steering wheel, indicating the driver’s intended direction.

- Yaw Rate Sensor: This sensor measures the vehicle’s rotation around its vertical axis.

- Lateral Acceleration Sensor: This sensor measures the sideways force acting on the vehicle.

- ESP Control Module: This module processes data from all sensors and controls the braking and engine intervention.

The system’s complexity means that a seemingly minor issue can trigger the “ESP Visit Workshop” message. For example, a faulty wheel speed sensor can disrupt the ESP’s ability to accurately monitor wheel speeds, leading to erroneous interventions. Similarly, a malfunctioning steering angle sensor can provide incorrect data, causing the ESP to misinterpret the driver’s intentions.

2. Common Causes of the ESP “Visit Workshop” Message

Several factors can trigger the “ESP Visit Workshop” message in your Mercedes W203. Identifying the root cause is crucial for effective repair. Here are some common culprits:

- Faulty Wheel Speed Sensors: Damaged or dirty wheel speed sensors are a frequent cause. These sensors are exposed to road debris and can fail over time.

- Steering Angle Sensor Malfunction: The steering angle sensor can become misaligned or fail, especially after wheel alignments or suspension work.

- Low Battery Voltage: A weak or failing battery can cause erratic behavior in the ESP system. The ESP module requires a stable voltage supply to function correctly.

- ESP Control Module Failure: Although less common, the ESP control module itself can fail due to electrical issues or internal component damage.

- Brake Light Switch Issues: A faulty brake light switch can disrupt the ESP system, as it provides critical information about brake application.

- Yaw Rate Sensor Problems: The yaw rate sensor can fail due to physical damage or electrical issues.

- Wiring and Connector Problems: Damaged or corroded wiring and connectors can interrupt the signal flow between components, leading to ESP faults.

- Software Glitches: Sometimes, software glitches in the ESP module can trigger false warnings.

Here is a table summarizing these causes:

| Cause |

Description |

Potential Symptoms |

| Faulty Wheel Speed Sensors |

Damaged or dirty sensors disrupt accurate wheel speed monitoring. |

ABS light, ESP light, traction control issues |

| Steering Angle Sensor |

Misalignment or failure affects ESP’s ability to interpret steering input. |

ESP light, difficulty steering, unstable handling |

| Low Battery Voltage |

Insufficient voltage causes erratic ESP behavior. |

ESP light, other electrical issues, starting problems |

| ESP Control Module Failure |

Internal damage or electrical issues lead to module malfunction. |

ESP light, complete ESP failure, other system malfunctions |

| Brake Light Switch |

Faulty switch disrupts brake application signal to ESP. |

ESP light, brake lights not working correctly, shifting problems |

| Yaw Rate Sensor |

Physical or electrical damage affects vehicle rotation measurement. |

ESP light, unstable handling, difficulty cornering |

| Wiring/Connector Problems |

Damaged wiring interrupts signal flow between ESP components. |

Intermittent ESP light, other electrical issues, system instability |

| Software Glitches |

Software errors within the ESP module trigger false warnings. |

Intermittent ESP light, no apparent mechanical issues, system reset needed |

Recognizing these common causes is the first step toward diagnosing and resolving the ESP “Visit Workshop” message.

3. Step-by-Step Diagnostic Procedures

Diagnosing the “ESP Visit Workshop” message requires a systematic approach. Follow these steps to identify the root cause:

- Visual Inspection:

- Check for any visible damage to wheel speed sensors, wiring, and connectors.

- Inspect the brake light switch for proper operation.

- Examine the battery terminals for corrosion and ensure the battery is fully charged.

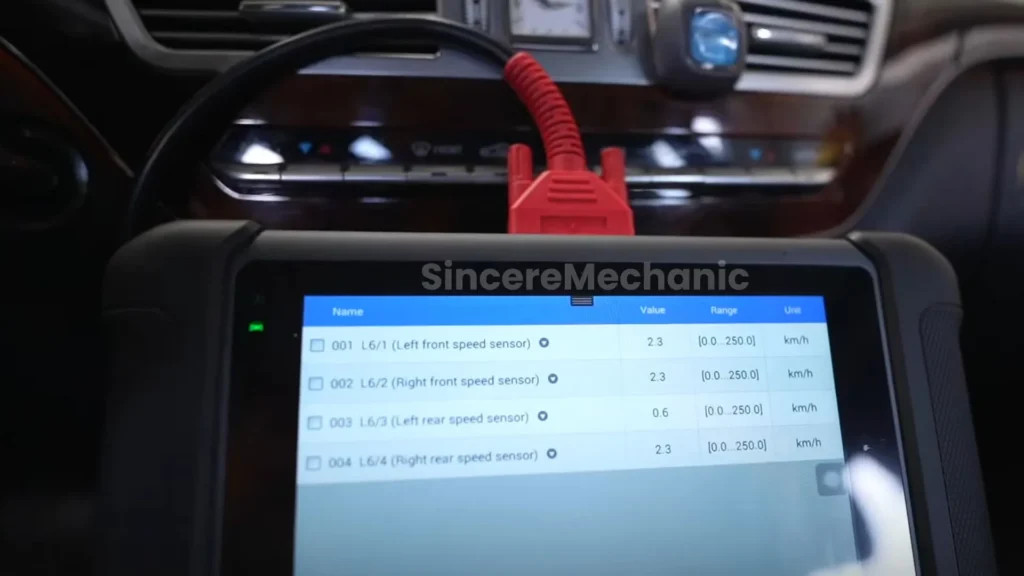

- Read Diagnostic Trouble Codes (DTCs):

- Use an OBD-II scanner compatible with Mercedes-Benz vehicles to read the DTCs stored in the ESP module.

- Record all DTCs and research their meaning in the Mercedes-Benz service manual.

- Tools available at CARDIAGTECH.NET can greatly assist in this process.

- Wheel Speed Sensor Testing:

- Use a multimeter to measure the resistance of each wheel speed sensor. Compare the readings to the manufacturer’s specifications.

- Inspect the sensor rings (tone wheels) for damage or debris.

- Steering Angle Sensor Calibration:

- Use a diagnostic tool to check the steering angle sensor’s calibration.

- If necessary, perform a steering angle sensor calibration procedure.

- Battery Voltage Testing:

- Use a voltmeter to check the battery voltage with the engine off and running.

- Ensure the battery voltage is within the specified range (typically 12.6V with the engine off and 13.5-14.5V with the engine running).

- Component-Level Testing:

- If the previous steps do not reveal the issue, perform component-level testing on the ESP control module, yaw rate sensor, and lateral acceleration sensor.

- Refer to the Mercedes-Benz service manual for specific testing procedures.

**Step-by-Step Diagnostic Table**

| Step | Procedure | Description | Tools Needed |

| ---- | ------------------------------ | -------------------------------------------------------------- | ------------------------------------------------------- |

| 1 | Visual Inspection | Check for visible damage to sensors, wiring, and connectors. | Flashlight, Inspection Mirror |

| 2 | Read DTCs | Use an OBD-II scanner to read and record diagnostic codes. | OBD-II Scanner (e.g., Autel MaxiSys, iCarsoft MB V3.0) |

| 3 | Wheel Speed Sensor Testing | Measure resistance and inspect sensor rings. | Multimeter, Socket Set |

| 4 | Steering Angle Sensor Calibration | Check and calibrate the steering angle sensor. | Diagnostic Tool (e.g., STAR Diagnostic System) |

| 5 | Battery Voltage Testing | Check battery voltage with engine off and running. | Voltmeter |

| 6 | Component-Level Testing | Test ESP module, yaw rate sensor, and lateral acceleration. | Mercedes-Benz Service Manual, Multimeter |

Performing these diagnostic steps meticulously will help you pinpoint the source of the ESP fault.

4. Advanced Troubleshooting Techniques

If the basic diagnostic steps don’t solve the problem, advanced troubleshooting techniques may be required. Here are some methods to consider:

-

Wiring Harness Inspection:

-

Thoroughly inspect the wiring harness for any signs of damage, corrosion, or shorts.

-

Use a wiring diagram to trace the circuits related to the ESP system.

-

Check for loose or corroded connectors.

-

CAN Bus Diagnostics:

-

The ESP system relies on the Controller Area Network (CAN) bus to communicate with other modules.

-

Use a CAN bus analyzer to monitor the communication between the ESP module and other modules.

-

Identify any communication errors or missing messages.

-

Signal Tracing:

-

Use an oscilloscope to trace the signals from the sensors to the ESP module.

-

Look for any signal distortions or interruptions.

-

Module Simulation:

-

Use a module simulator to simulate the signals from the sensors and test the ESP module’s response.

-

This can help determine if the ESP module itself is faulty.

-

Software Updates:

-

Ensure the ESP module has the latest software version.

-

Software updates can fix known bugs and improve system performance.

Advanced Troubleshooting Table

| Technique |

Description |

Tools Needed |

| Wiring Harness Inspection |

Inspect for damage, corrosion, and shorts in the wiring harness. |

Wiring Diagram, Multimeter, Inspection Tools |

| CAN Bus Diagnostics |

Monitor communication between ESP and other modules. |

CAN Bus Analyzer |

| Signal Tracing |

Trace signals from sensors to the ESP module. |

Oscilloscope |

| Module Simulation |

Simulate sensor signals to test the ESP module’s response. |

Module Simulator |

| Software Updates |

Ensure ESP module has the latest software version. |

Mercedes-Benz Diagnostic Software (e.g., XENTRY/DAS) |

Employing these advanced techniques can help you uncover more elusive ESP faults.

5. Component-Level Repair and Replacement

Once you have identified the faulty component, you can proceed with repair or replacement. Here are some guidelines for common components:

-

Wheel Speed Sensors:

-

Clean the sensor and sensor ring if they are dirty.

-

Replace the sensor if it is damaged or malfunctioning.

-

Ensure the new sensor is properly installed and torqued to the manufacturer’s specifications.

-

Steering Angle Sensor:

-

Calibrate the sensor after replacement or realignment.

-

Follow the Mercedes-Benz service manual for the calibration procedure.

-

ESP Control Module:

-

Ensure the replacement module is compatible with your vehicle.

-

Program the new module with the correct vehicle-specific data.

-

This may require specialized diagnostic tools.

-

Brake Light Switch:

-

Replace the switch if it is faulty.

-

Adjust the switch position according to the manufacturer’s instructions.

-

Yaw Rate Sensor and Lateral Acceleration Sensor:

-

Replace the sensor if it is damaged or malfunctioning.

-

Ensure the new sensor is properly mounted and connected.

Component Repair/Replacement Table

| Component |

Action |

Notes |

| Wheel Speed Sensors |

Clean or Replace |

Ensure proper installation and torque. |

| Steering Angle Sensor |

Calibrate After Replacement |

Follow Mercedes-Benz service manual for calibration. |

| ESP Control Module |

Replace and Program |

Ensure compatibility and program with vehicle-specific data. |

| Brake Light Switch |

Replace and Adjust |

Adjust switch position per manufacturer instructions. |

| Yaw/Lateral Sensors |

Replace |

Ensure proper mounting and connection. |

When replacing components, always use high-quality parts from reputable suppliers to ensure proper performance and reliability. CARDIAGTECH.NET can help you source these components.

CARDIAGTECH.NET offers a range of diagnostic tools that can greatly assist in diagnosing and resolving ESP faults in your Mercedes W203. Here are some recommended tools:

-

OBD-II Scanners:

-

Choose a scanner that is compatible with Mercedes-Benz vehicles and can read ESP-specific DTCs.

-

Models like the Autel MaxiSys and iCarsoft MB V3.0 are highly recommended.

-

Mercedes-Benz Diagnostic Software:

-

The XENTRY/DAS (Diagnostic Assistance System) software is the official Mercedes-Benz diagnostic tool.

-

It provides comprehensive diagnostic capabilities, including DTC reading, component testing, and programming.

-

Multimeters and Oscilloscopes:

-

These tools are essential for testing sensors, wiring, and circuits.

-

Choose high-quality models with accurate readings.

-

CAN Bus Analyzers:

-

These tools can monitor the communication on the CAN bus and identify any errors or missing messages.

Recommended Diagnostic Tools

| Tool |

Description |

Use Case |

| Autel MaxiSys |

Advanced OBD-II scanner with comprehensive Mercedes-Benz diagnostics. |

Reading DTCs, component testing, advanced diagnostics. |

| iCarsoft MB V3.0 |

User-friendly OBD-II scanner for Mercedes-Benz vehicles. |

Reading DTCs, basic diagnostics. |

| XENTRY/DAS (Mercedes-Benz Software) |

Official Mercedes-Benz diagnostic software. |

Comprehensive diagnostics, programming, and component testing. |

| Multimeter |

Measures voltage, current, and resistance. |

Testing sensors, wiring, and circuits. |

| Oscilloscope |

Displays electrical signals over time. |

Signal tracing and analysis. |

| CAN Bus Analyzer |

Monitors communication on the CAN bus. |

Identifying communication errors. |

Investing in these diagnostic tools can save you time and money by allowing you to accurately diagnose and repair ESP faults yourself. Contact CARDIAGTECH.NET at +1 (641) 206-8880 or visit us at 276 Reock St, City of Orange, NJ 07050, United States, to find the right tools for your needs.

7. Preventative Measures to Avoid ESP Faults

Preventing ESP faults is always better than dealing with them after they occur. Here are some preventative measures you can take:

-

Regular Vehicle Maintenance:

-

Follow the manufacturer’s recommended maintenance schedule.

-

Pay attention to brake system maintenance, as it directly affects the ESP system.

-

Wheel Speed Sensor Care:

-

Keep the wheel speed sensors clean and free of debris.

-

Inspect the sensors regularly for damage.

-

Battery Maintenance:

-

Ensure the battery is in good condition and fully charged.

-

Clean the battery terminals to prevent corrosion.

-

Proper Wheel Alignment:

-

Maintain proper wheel alignment to prevent steering angle sensor issues.

-

Avoid Harsh Driving Conditions:

-

Avoid driving in harsh conditions that can damage sensors and wiring.

Preventative Maintenance Schedule

| Task |

Frequency |

Notes |

| Brake System Inspection |

Every 6 Months |

Check brake pads, rotors, and brake lines. |

| Wheel Speed Sensor Cleaning |

Annually |

Remove debris and inspect for damage. |

| Battery Check |

Every 6 Months |

Ensure battery is fully charged and terminals are clean. |

| Wheel Alignment |

Annually or After Suspension Work |

Prevents steering angle sensor issues. |

| Wiring Harness Inspection |

Annually |

Check for damage or corrosion. |

By taking these preventative measures, you can minimize the risk of ESP faults and keep your Mercedes W203 running smoothly.

8. Real-World Case Studies and Solutions

Examining real-world case studies can provide valuable insights into diagnosing and resolving ESP faults. Here are a few examples:

-

Case Study 1: Faulty Wheel Speed Sensor

-

Symptom: “ESP Visit Workshop” message, ABS light on, traction control issues.

-

Diagnosis: DTC indicated a faulty wheel speed sensor on the front left wheel.

-

Solution: Replaced the faulty wheel speed sensor. Cleared the DTCs. Performed a road test to verify the repair.

-

Tools Used: OBD-II scanner, multimeter, socket set.

-

Case Study 2: Steering Angle Sensor Misalignment

-

Symptom: “ESP Visit Workshop” message after a wheel alignment.

-

Diagnosis: DTC indicated a steering angle sensor misalignment.

-

Solution: Performed a steering angle sensor calibration using a diagnostic tool. Cleared the DTCs.

-

Tools Used: Diagnostic tool with steering angle sensor calibration function.

-

Case Study 3: Low Battery Voltage

-

Symptom: Intermittent “ESP Visit Workshop” message, especially during cold starts.

-

Diagnosis: Battery voltage was below the specified range.

-

Solution: Replaced the weak battery with a new one. Cleared the DTCs.

-

Tools Used: Voltmeter.

Case Study Summary

| Case |

Symptom |

Diagnosis |

Solution |

Tools Used |

| Case 1 |

ESP, ABS, Traction Control Issues |

Faulty Wheel Speed Sensor |

Replaced Wheel Speed Sensor |

OBD-II Scanner, Multimeter, Socket Set |

| Case 2 |

ESP Message After Wheel Alignment |

Steering Angle Sensor Misalignment |

Performed Steering Angle Sensor Calibration |

Diagnostic Tool with Steering Angle Sensor Calibration Function |

| Case 3 |

Intermittent ESP Message During Starts |

Low Battery Voltage |

Replaced Battery |

Voltmeter |

These case studies demonstrate the importance of accurate diagnosis and targeted repairs.

9. The Importance of Regular Maintenance

Regular maintenance is essential for keeping your Mercedes W203 in top condition and preventing ESP faults. Here are some key maintenance tasks:

-

Brake System Service:

-

Inspect brake pads, rotors, and brake lines regularly.

-

Replace worn brake components promptly.

-

Flush the brake fluid every two years to maintain optimal brake performance.

-

Tire Maintenance:

-

Maintain proper tire pressure.

-

Rotate tires regularly to ensure even wear.

-

Replace worn tires promptly.

-

Suspension System Inspection:

-

Inspect the suspension components for wear and damage.

-

Replace worn suspension components to maintain proper handling and stability.

-

Electrical System Check:

-

Check the battery voltage and condition.

-

Inspect wiring and connectors for damage or corrosion.

Regular Maintenance Checklist

| System |

Task |

Frequency |

Notes |

| Brake System |

Inspect Pads, Rotors, Brake Lines |

Every 6 Months |

Replace worn components; flush brake fluid every two years. |

| Tires |

Check Pressure, Rotate |

Monthly |

Maintain proper pressure; rotate every 6,000-8,000 miles. |

| Suspension |

Inspect Components |

Annually |

Check for wear and damage. |

| Electrical |

Check Battery, Wiring |

Annually |

Ensure battery is in good condition; inspect wiring for corrosion. |

By following a regular maintenance schedule, you can prolong the life of your Mercedes W203 and minimize the risk of ESP faults.

CARDIAGTECH.NET is your trusted partner in maintaining the performance and safety of your vehicle. Contact us at +1 (641) 206-8880 or visit us at 276 Reock St, City of Orange, NJ 07050, United States, to learn more about our diagnostic tools and services. Don’t let the “ESP Visit Workshop” message compromise your driving experience.