Mercedes Benz Sprinter Adblue Tank problems can be frustrating, but understanding the system and available solutions can save you time and money. CARDIAGTECH.NET offers tools and expertise to diagnose and address these issues effectively, ensuring your Sprinter runs smoothly and efficiently. Explore preventative maintenance, sensor troubleshooting, and component replacements to keep your diesel exhaust fluid system in top shape.

Contents

- 1. Understanding the Mercedes Benz Sprinter Adblue System

- 1.1. Components of the Adblue System

- 1.2. How the Adblue System Works

- 1.3. Importance of the Adblue System for Emission Control

- 2. Common Issues with the Mercedes Benz Sprinter Adblue Tank

- 2.1. DEF Level Sensor Problems

- 2.2. DEF Pump Failure

- 2.3. DEF Injector Clogging

- 2.4. Adblue Tank Heater Malfunction

- 2.5. NOx Sensor Failure

- 3. Diagnosing Adblue Tank Problems

- 3.1. Using a Diagnostic Scan Tool

- 3.2. Visual Inspection Techniques

- 3.3. Testing Adblue Quality

- 3.4. Checking for Clogged Components

- 4. Repairing and Maintaining the Mercedes Benz Sprinter Adblue Tank

- 4.1. Cleaning or Replacing the DEF Injector

- 4.2. Replacing the DEF Pump

- 4.3. Replacing the Adblue Tank

- 4.4. Adblue Tank Sensor Replacement

- 4.5. Regular Maintenance Tips

- 5. Choosing the Right Adblue Fluid for Your Sprinter

- 5.1. Understanding DEF Specifications (ISO 22241)

- 5.2. Brands and Types of DEF

- 5.3. Where to Buy DEF

- 6. The Role of CARDIAGTECH.NET in Adblue System Maintenance

- 6.1. Diagnostic Tools Available at CARDIAGTECH.NET

- 6.2. Replacement Parts for Adblue Systems

- 6.3. Expert Advice and Support

- 7. Understanding Adblue System Fault Codes

- 7.1. Common Fault Codes Related to Adblue Tank

- 7.2. How to Interpret Fault Codes

- 7.3. Resetting the System After Repairs

- 8. Modifying and Upgrading Your Adblue System

- 8.1. Potential Benefits of Upgrades

- 8.2. Risks and Considerations

- 8.3. Aftermarket Options

- 9. Legal and Environmental Considerations

- 9.1. Emission Regulations and Compliance

- 9.2. Consequences of Non-Compliance

- 9.3. Environmental Responsibility

- 10. Preventing Future Adblue Tank Issues

- 10.1. Best Practices for Adblue System Care

- 10.2. Storage Tips for DEF

- 10.3. Scheduled Maintenance

- 11. Real-World Case Studies

- 11.1. Case Study 1: DEF Level Sensor Failure

- 11.2. Case Study 2: Clogged DEF Injector

- 11.3. Case Study 3: DEF Pump Failure

- 12. Addressing Common Misconceptions

- 12.1. “Adblue is Just a Gimmick”

- 12.2. “Any DEF Will Work”

- 12.3. “You Can Just Top Off the Tank”

- 12.4. “Adblue Systems Don’t Need Maintenance”

- 13. Future Trends in Adblue Technology

- 13.1. Advancements in SCR Technology

- 13.2. Integration with Vehicle Systems

- 13.3. Alternative Emission Reduction Technologies

- 14. Frequently Asked Questions (FAQ)

1. Understanding the Mercedes Benz Sprinter Adblue System

The Adblue system, also known as the Selective Catalytic Reduction (SCR) system, is crucial for reducing harmful nitrogen oxide (NOx) emissions from your Mercedes Benz Sprinter’s diesel engine. Diesel exhaust fluid (DEF), stored in the Adblue tank, is injected into the exhaust stream, where it reacts with NOx in the catalytic converter to produce harmless nitrogen and water.

1.1. Components of the Adblue System

Understanding the components of the Adblue system is essential for effective diagnostics and repairs. Here’s a breakdown of the key parts:

- Adblue Tank: Stores the diesel exhaust fluid (DEF).

- DEF Pump: Transfers DEF from the tank to the injector.

- DEF Injector: Sprays DEF into the exhaust stream.

- SCR Catalytic Converter: Facilitates the chemical reaction that reduces NOx emissions.

- NOx Sensors: Monitor NOx levels in the exhaust gas.

- Temperature Sensors: Ensure optimal operating conditions for the SCR system.

- Control Unit (ECU): Manages the entire system based on sensor inputs.

1.2. How the Adblue System Works

The Adblue system operates through a series of carefully orchestrated steps:

- Monitoring: NOx sensors continuously monitor the levels of nitrogen oxides in the exhaust gas.

- Injection: When NOx levels exceed permissible limits, the control unit calculates the amount of DEF needed. The DEF pump then delivers DEF to the injector.

- Reaction: The DEF injector sprays DEF into the exhaust stream ahead of the SCR catalytic converter. At high temperatures within the converter, DEF decomposes into ammonia.

- Conversion: Ammonia reacts with NOx on the surface of the catalyst, converting them into nitrogen and water.

- Feedback: The NOx sensors downstream of the converter provide feedback to the control unit, ensuring the system operates efficiently and effectively.

1.3. Importance of the Adblue System for Emission Control

The Adblue system plays a vital role in reducing harmful emissions from diesel engines. By converting NOx into harmless substances, it helps to:

- Meet Emission Standards: Ensure compliance with stringent environmental regulations, such as those set by the EPA and Euro standards.

- Improve Air Quality: Reduce air pollution and associated health risks, contributing to cleaner and healthier environments.

- Enhance Engine Performance: Maintain optimal engine performance by preventing the buildup of deposits in the exhaust system.

2. Common Issues with the Mercedes Benz Sprinter Adblue Tank

Several issues can arise with the Mercedes Benz Sprinter Adblue tank and its related components. Identifying these common problems can help you diagnose and address them promptly.

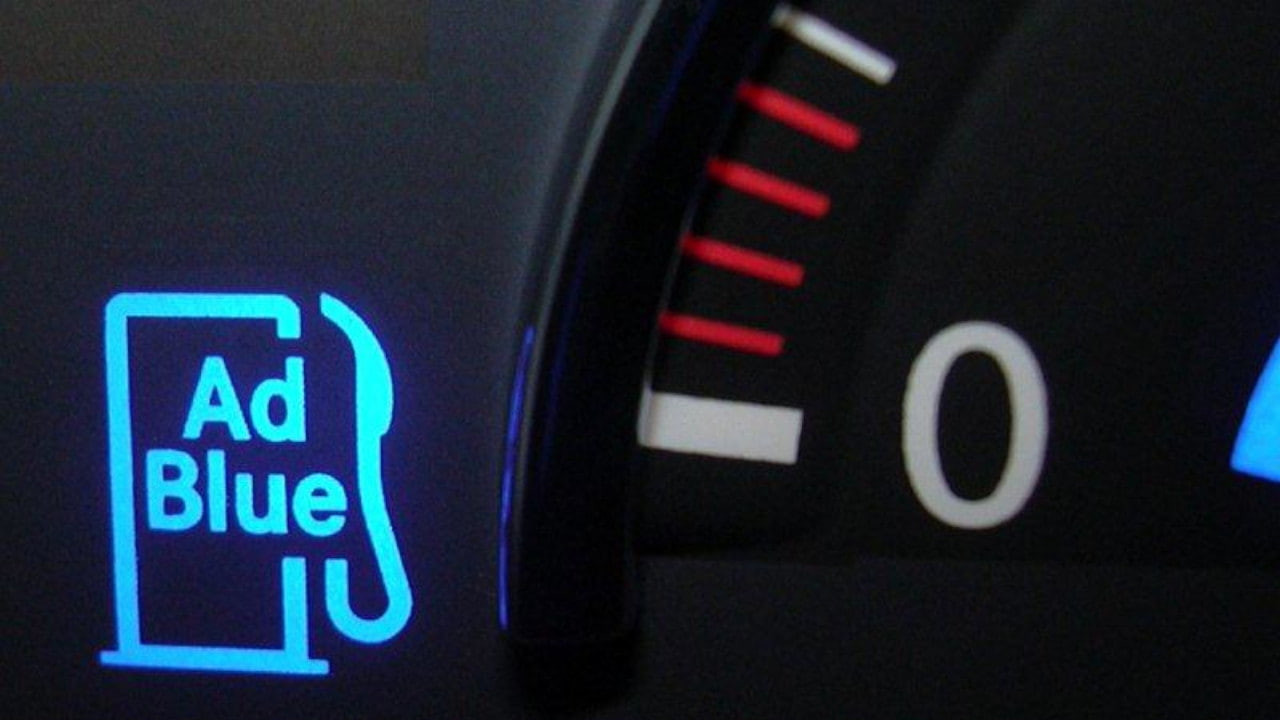

2.1. DEF Level Sensor Problems

The DEF level sensor monitors the amount of diesel exhaust fluid in the tank. Common problems include:

- Inaccurate Readings: The sensor may provide incorrect readings, indicating a full tank when it’s empty or vice versa.

- Sensor Failure: The sensor can fail completely, triggering a fault code and preventing the system from functioning correctly.

- Corrosion: Corrosion can affect the sensor’s accuracy, leading to false readings.

Troubleshooting Steps:

- Visual Inspection: Check for any visible damage or corrosion on the sensor and its wiring.

- Diagnostic Scan: Use a diagnostic tool to read fault codes related to the DEF level sensor. CARDIAGTECH.NET offers a range of diagnostic tools compatible with Mercedes Benz Sprinter models.

- Sensor Testing: Use a multimeter to test the sensor’s resistance and voltage output. Compare the readings with the manufacturer’s specifications.

2.2. DEF Pump Failure

The DEF pump is responsible for delivering diesel exhaust fluid from the tank to the injector. Common issues include:

- Pump Motor Failure: The motor can fail due to wear and tear, preventing the pump from operating.

- Clogged Filter: A clogged filter can restrict DEF flow, reducing the pump’s efficiency.

- Electrical Issues: Wiring problems or a faulty relay can prevent the pump from receiving power.

Troubleshooting Steps:

- Check Power Supply: Verify that the pump is receiving power using a multimeter.

- Inspect Filter: Check the DEF filter for clogs and replace if necessary.

- Pump Testing: Use a diagnostic tool to activate the pump and monitor its operation. Listen for unusual noises that may indicate a problem.

2.3. DEF Injector Clogging

The DEF injector sprays diesel exhaust fluid into the exhaust stream. Clogging is a common issue due to DEF crystallization.

- Crystallization: DEF can crystallize inside the injector, blocking the nozzle and preventing proper spray.

- Contamination: Contaminants in the DEF can also clog the injector.

Troubleshooting Steps:

- Visual Inspection: Remove the injector and inspect it for signs of clogging or crystallization.

- Cleaning: Clean the injector using a DEF-compatible cleaner. You can also use an ultrasonic cleaner for more thorough cleaning.

- Testing: After cleaning, test the injector to ensure it sprays properly.

2.4. Adblue Tank Heater Malfunction

In cold climates, the Adblue tank heater prevents DEF from freezing. Malfunctions can lead to system errors.

- Heater Failure: The heater element can fail, preventing DEF from thawing in cold temperatures.

- Wiring Issues: Damaged wiring or a faulty relay can prevent the heater from receiving power.

Troubleshooting Steps:

- Check Power Supply: Verify that the heater is receiving power using a multimeter.

- Heater Resistance: Test the resistance of the heater element. Compare the reading with the manufacturer’s specifications.

- Wiring Inspection: Inspect the wiring for any signs of damage or corrosion.

2.5. NOx Sensor Failure

NOx sensors monitor the levels of nitrogen oxides in the exhaust gas. Failure can disrupt the entire SCR system.

- Sensor Contamination: Contaminants can coat the sensor, affecting its accuracy.

- Electrical Issues: Wiring problems or a faulty sensor can cause incorrect readings or complete failure.

Troubleshooting Steps:

- Diagnostic Scan: Use a diagnostic tool to read fault codes related to the NOx sensors.

- Sensor Testing: Use a multimeter to test the sensor’s resistance and voltage output.

- Visual Inspection: Check for any visible damage or contamination on the sensor.

3. Diagnosing Adblue Tank Problems

Accurate diagnosis is crucial for addressing Adblue tank problems effectively. Here’s a step-by-step guide to help you diagnose common issues.

3.1. Using a Diagnostic Scan Tool

A diagnostic scan tool is an indispensable tool for diagnosing Adblue system problems. CARDIAGTECH.NET offers a variety of scan tools compatible with Mercedes Benz Sprinter models.

- Connect the Scan Tool: Plug the scan tool into the OBD-II port, typically located under the dashboard.

- Read Fault Codes: Turn on the ignition and use the scan tool to read any stored fault codes related to the Adblue system.

- Interpret Codes: Refer to the Mercedes Benz Sprinter service manual or online resources to interpret the fault codes.

- Clear Codes: After addressing the issue, clear the fault codes and retest the system.

3.2. Visual Inspection Techniques

A thorough visual inspection can often reveal obvious problems with the Adblue system.

- Check for Leaks: Inspect the Adblue tank, pump, and lines for any signs of leaks.

- Inspect Wiring: Check the wiring for damage, corrosion, or loose connections.

- Examine Components: Look for any visible damage or wear on the Adblue tank, pump, and injector.

3.3. Testing Adblue Quality

The quality of the diesel exhaust fluid can significantly impact the performance of the Adblue system.

- Use a Refractometer: A refractometer measures the concentration of DEF. The ideal concentration is 32.5% urea.

- Check for Contamination: Look for any signs of contamination in the DEF, such as sediment or discoloration.

- Use Quality DEF: Always use high-quality DEF that meets ISO 22241 standards.

3.4. Checking for Clogged Components

Clogged components can restrict DEF flow and cause system errors.

- Inspect the DEF Filter: Remove the DEF filter and inspect it for clogs. Replace if necessary.

- Check the Injector: Remove the injector and inspect it for crystallization or contamination.

- Inspect the Lines: Check the DEF lines for any obstructions.

4. Repairing and Maintaining the Mercedes Benz Sprinter Adblue Tank

Proper maintenance and timely repairs are essential for ensuring the long-term reliability of your Mercedes Benz Sprinter Adblue system.

4.1. Cleaning or Replacing the DEF Injector

A clogged DEF injector can be cleaned or replaced, depending on the severity of the clog.

- Cleaning: Soak the injector in a DEF-compatible cleaner for several hours. Use a soft brush to remove any remaining deposits. Rinse thoroughly with clean water.

- Replacement: If the injector is severely clogged or damaged, replace it with a new one. CARDIAGTECH.NET offers high-quality replacement injectors for Mercedes Benz Sprinter models.

4.2. Replacing the DEF Pump

A faulty DEF pump should be replaced to ensure proper DEF delivery.

- Disconnect Electrical Connections: Disconnect the electrical connections to the pump.

- Remove DEF Lines: Disconnect the DEF lines from the pump.

- Remove the Pump: Remove the pump from its mounting bracket.

- Install the New Pump: Install the new pump in the mounting bracket.

- Reconnect DEF Lines: Reconnect the DEF lines to the pump.

- Reconnect Electrical Connections: Reconnect the electrical connections to the pump.

- Test the System: Use a diagnostic tool to test the system and ensure the new pump is functioning correctly.

4.3. Replacing the Adblue Tank

In some cases, the Adblue tank may need to be replaced due to damage or failure.

- Drain the DEF: Drain the DEF from the tank.

- Disconnect Electrical Connections: Disconnect the electrical connections to the tank.

- Remove DEF Lines: Disconnect the DEF lines from the tank.

- Remove the Tank: Remove the tank from its mounting brackets.

- Install the New Tank: Install the new tank in the mounting brackets.

- Reconnect DEF Lines: Reconnect the DEF lines to the tank.

- Reconnect Electrical Connections: Reconnect the electrical connections to the tank.

- Fill with DEF: Fill the tank with high-quality DEF.

- Test the System: Use a diagnostic tool to test the system and ensure the new tank is functioning correctly.

4.4. Adblue Tank Sensor Replacement

Replacing a faulty Adblue tank sensor can restore proper monitoring of DEF levels.

- Drain the DEF: Drain the DEF from the tank to a level below the sensor.

- Disconnect Electrical Connections: Disconnect the electrical connections to the sensor.

- Remove the Sensor: Remove the sensor from the tank.

- Install the New Sensor: Install the new sensor into the tank.

- Reconnect Electrical Connections: Reconnect the electrical connections to the sensor.

- Refill with DEF: Refill the tank with high-quality DEF.

- Test the System: Use a diagnostic tool to test the system and ensure the new sensor is functioning correctly.

4.5. Regular Maintenance Tips

Regular maintenance can prevent many Adblue system problems.

- Use High-Quality DEF: Always use high-quality DEF that meets ISO 22241 standards.

- Check DEF Levels: Regularly check the DEF level and refill as needed.

- Inspect for Leaks: Periodically inspect the Adblue tank, pump, and lines for leaks.

- Replace DEF Filter: Replace the DEF filter according to the manufacturer’s recommendations.

- Clean Injector: Periodically clean the DEF injector to prevent clogging.

- Monitor NOx Sensors: Monitor the NOx sensors for proper functioning.

5. Choosing the Right Adblue Fluid for Your Sprinter

Selecting the correct Adblue fluid is vital for the optimal performance and longevity of your Sprinter’s SCR system.

5.1. Understanding DEF Specifications (ISO 22241)

Diesel Exhaust Fluid (DEF) must meet the ISO 22241 standard to ensure its purity and effectiveness. This standard specifies the required concentration of urea (32.5%) and limits the allowable levels of contaminants.

- Urea Concentration: The DEF must contain 32.5% urea. This concentration is crucial for the proper chemical reaction in the SCR catalytic converter.

- Purity: The DEF must be free from contaminants such as metals, phosphates, and other chemicals that can damage the SCR system.

- Storage: Proper storage is essential to maintain the quality of DEF. It should be stored in a clean, sealed container at temperatures between 12°F (-11°C) and 86°F (30°C).

5.2. Brands and Types of DEF

Several brands offer DEF that meets the ISO 22241 standard. Some popular options include:

- AdBlue: A widely recognized brand that meets all necessary specifications.

- Peak BlueDEF: A popular choice known for its quality and availability.

- Valvoline DEF: Another reputable brand that offers reliable performance.

5.3. Where to Buy DEF

DEF is readily available at various locations:

- Auto Parts Stores: Stores like AutoZone, Advance Auto Parts, and O’Reilly Auto Parts carry DEF.

- Truck Stops: Truck stops such as Pilot Flying J and TravelCenters of America offer DEF at the pump.

- Online Retailers: Online retailers like Amazon sell DEF in various quantities.

- Mercedes Benz Dealerships: Dealerships also sell DEF, ensuring you get the correct fluid for your Sprinter.

6. The Role of CARDIAGTECH.NET in Adblue System Maintenance

CARDIAGTECH.NET offers a range of products and services to help you maintain your Mercedes Benz Sprinter Adblue system.

6.1. Diagnostic Tools Available at CARDIAGTECH.NET

CARDIAGTECH.NET provides a variety of diagnostic tools compatible with Mercedes Benz Sprinter models. These tools can help you quickly identify and diagnose Adblue system problems.

- OBD-II Scanners: Basic OBD-II scanners can read and clear fault codes related to the Adblue system.

- Professional Diagnostic Tools: Advanced diagnostic tools offer more comprehensive features, such as live data streaming, component testing, and programming capabilities.

- Mercedes Benz Specific Tools: Specialized tools designed specifically for Mercedes Benz vehicles provide the most accurate and detailed diagnostics.

6.2. Replacement Parts for Adblue Systems

CARDIAGTECH.NET offers a wide selection of replacement parts for Adblue systems, including:

- DEF Pumps: High-quality replacement DEF pumps to ensure proper DEF delivery.

- DEF Injectors: Replacement injectors to restore proper spray and atomization of DEF.

- NOx Sensors: Replacement NOx sensors to monitor nitrogen oxide levels accurately.

- Adblue Tanks: Replacement tanks for damaged or leaking units.

- DEF Level Sensors: Replacement sensors to provide accurate DEF level readings.

6.3. Expert Advice and Support

CARDIAGTECH.NET provides expert advice and support to help you diagnose and repair Adblue system problems. Our team of experienced technicians can answer your questions and provide guidance on troubleshooting and maintenance procedures. Contact us at +1 (641) 206-8880 for assistance.

7. Understanding Adblue System Fault Codes

Fault codes provide valuable information about the nature of Adblue system problems. Here are some common fault codes and their meanings.

7.1. Common Fault Codes Related to Adblue Tank

| Fault Code | Description | Possible Causes |

|---|---|---|

| P203F | Reductant Level Too Low | Low DEF level, faulty DEF level sensor, leaks in the DEF system. |

| P20E8 | Reductant Dosage Control System Too Low | Faulty DEF pump, clogged DEF injector, leaks in the DEF system, incorrect DEF concentration. |

| P204F | Reductant System Performance | Faulty NOx sensor, clogged SCR catalytic converter, leaks in the DEF system, incorrect DEF concentration. |

| P13E77B | DEF Level Sensor Circuit Range/Performance | Faulty DEF level sensor, wiring problems, corrosion in the sensor connector. |

| U010E | Lost Communication with Reductant Control Module | Wiring problems, faulty control module, power supply issues. |

| P203D | Reductant Level Sensor Circuit High | Faulty DEF level sensor, wiring problems, corrosion in the sensor connector. |

| P203E | Reductant Level Sensor Circuit Low | Faulty DEF level sensor, wiring problems, corrosion in the sensor connector. |

| P20BA | Reductant Heater Control Circuit/Open | Faulty DEF tank heater, wiring problems, faulty relay. |

| P20BD | Reductant Heater Control Circuit Low | Faulty DEF tank heater, wiring problems, faulty relay. |

| P20BE | Reductant Heater Control Circuit High | Faulty DEF tank heater, wiring problems, faulty relay. |

| P2047 | Reductant Injector Circuit Open | Faulty DEF injector, wiring problems, corrosion in the injector connector. |

| P2048 | Reductant Injector Circuit Short to Ground | Faulty DEF injector, wiring problems, corrosion in the injector connector. |

| P2049 | Reductant Injector Circuit Short to Battery | Faulty DEF injector, wiring problems, corrosion in the injector connector. |

| P205B | Reductant Tank Temperature Sensor Circuit Range/Performance | Faulty DEF tank temperature sensor, wiring problems, corrosion in the sensor connector. |

| P205C | Reductant Tank Temperature Sensor Circuit Low | Faulty DEF tank temperature sensor, wiring problems, corrosion in the sensor connector. |

| P205D | Reductant Tank Temperature Sensor Circuit High | Faulty DEF tank temperature sensor, wiring problems, corrosion in the sensor connector. |

7.2. How to Interpret Fault Codes

- Use a Diagnostic Tool: Connect a diagnostic tool to the OBD-II port and read the stored fault codes.

- Refer to Service Manual: Consult the Mercedes Benz Sprinter service manual or online resources to interpret the fault codes.

- Troubleshooting: Follow the troubleshooting steps outlined in the service manual to diagnose and repair the problem.

- Clear Codes: After addressing the issue, clear the fault codes and retest the system.

7.3. Resetting the System After Repairs

After completing repairs, it’s essential to reset the Adblue system to ensure it functions correctly.

- Clear Fault Codes: Use a diagnostic tool to clear any stored fault codes.

- Perform a System Reset: Some diagnostic tools offer a system reset function that can reset the Adblue system parameters.

- Test the System: After resetting the system, test it to ensure it operates correctly.

8. Modifying and Upgrading Your Adblue System

While modifying or upgrading your Adblue system can enhance its performance, it’s essential to consider the potential consequences.

8.1. Potential Benefits of Upgrades

- Improved Efficiency: Upgrading certain components, such as the DEF injector, can improve the efficiency of the Adblue system.

- Enhanced Performance: Upgrades can enhance the overall performance of the SCR system, reducing emissions and improving fuel economy.

8.2. Risks and Considerations

- Warranty Issues: Modifying the Adblue system may void your vehicle’s warranty.

- Compliance: Ensure that any modifications comply with local emission regulations.

- Compatibility: Verify that any aftermarket parts are compatible with your Mercedes Benz Sprinter model.

8.3. Aftermarket Options

- Performance Injectors: Upgraded DEF injectors can provide more precise and efficient DEF delivery.

- Enhanced Pumps: High-performance DEF pumps can improve DEF flow and pressure.

- Advanced Control Units: Aftermarket control units can optimize the performance of the Adblue system.

9. Legal and Environmental Considerations

Understanding the legal and environmental aspects of Adblue systems is crucial for compliance and responsible vehicle ownership.

9.1. Emission Regulations and Compliance

- EPA Standards: The Environmental Protection Agency (EPA) sets emission standards for vehicles in the United States.

- Euro Standards: The European Union (EU) sets emission standards for vehicles in Europe.

- Compliance: Ensure that your Mercedes Benz Sprinter complies with all applicable emission regulations.

9.2. Consequences of Non-Compliance

- Fines: Violating emission regulations can result in significant fines.

- Vehicle Impoundment: In some cases, non-compliant vehicles may be impounded.

- Legal Penalties: Serious violations can lead to legal penalties.

9.3. Environmental Responsibility

- Reduce Emissions: Properly maintaining your Adblue system helps reduce harmful emissions and protect the environment.

- Use Quality DEF: Using high-quality DEF ensures the proper functioning of the SCR system.

- Proper Disposal: Dispose of used DEF and Adblue system components responsibly.

10. Preventing Future Adblue Tank Issues

Preventing future Adblue tank issues requires proactive maintenance and care.

10.1. Best Practices for Adblue System Care

- Regular Inspections: Periodically inspect the Adblue tank, pump, and lines for leaks or damage.

- Use Quality DEF: Always use high-quality DEF that meets ISO 22241 standards.

- Replace DEF Filter: Replace the DEF filter according to the manufacturer’s recommendations.

- Clean Injector: Periodically clean the DEF injector to prevent clogging.

- Monitor NOx Sensors: Monitor the NOx sensors for proper functioning.

10.2. Storage Tips for DEF

- Clean Container: Store DEF in a clean, sealed container.

- Temperature Control: Store DEF at temperatures between 12°F (-11°C) and 86°F (30°C).

- Avoid Contamination: Prevent contamination of DEF by keeping the container sealed and using a clean funnel when filling the tank.

10.3. Scheduled Maintenance

- Follow Recommendations: Follow the manufacturer’s recommendations for scheduled maintenance of the Adblue system.

- Keep Records: Keep records of all maintenance performed on the Adblue system.

- Address Issues Promptly: Address any Adblue system problems promptly to prevent further damage.

11. Real-World Case Studies

Examining real-world case studies can provide valuable insights into diagnosing and resolving Adblue tank issues.

11.1. Case Study 1: DEF Level Sensor Failure

- Problem: A Mercedes Benz Sprinter displayed a “Check Adblue Level” warning despite the tank being full.

- Diagnosis: A diagnostic scan revealed a fault code indicating a faulty DEF level sensor.

- Solution: The DEF level sensor was replaced, and the system was reset. The warning disappeared, and the system functioned correctly.

11.2. Case Study 2: Clogged DEF Injector

- Problem: A Mercedes Benz Sprinter experienced reduced engine performance and a “Check Engine” light.

- Diagnosis: A visual inspection revealed a clogged DEF injector.

- Solution: The DEF injector was removed and cleaned using a DEF-compatible cleaner. The injector was reinstalled, and the system was tested. The engine performance returned to normal, and the “Check Engine” light disappeared.

11.3. Case Study 3: DEF Pump Failure

- Problem: A Mercedes Benz Sprinter displayed a “Check Adblue System” warning and a fault code indicating a faulty DEF pump.

- Diagnosis: A diagnostic test confirmed that the DEF pump was not functioning.

- Solution: The DEF pump was replaced with a new one, and the system was reset. The warning disappeared, and the system functioned correctly.

12. Addressing Common Misconceptions

Several misconceptions surround Adblue systems. Addressing these can help you make informed decisions about maintenance and repairs.

12.1. “Adblue is Just a Gimmick”

- Fact: Adblue is essential for reducing harmful emissions and complying with environmental regulations.

12.2. “Any DEF Will Work”

- Fact: Only use DEF that meets ISO 22241 standards to ensure proper functioning and prevent damage to the SCR system.

12.3. “You Can Just Top Off the Tank”

- Fact: While topping off the tank is necessary, it’s essential to monitor DEF levels regularly and address any underlying issues that may be causing excessive DEF consumption.

12.4. “Adblue Systems Don’t Need Maintenance”

- Fact: Adblue systems require regular maintenance to ensure proper functioning and prevent problems.

13. Future Trends in Adblue Technology

The technology behind Adblue systems is continuously evolving. Staying informed about future trends can help you prepare for upcoming changes.

13.1. Advancements in SCR Technology

- Improved Catalysts: Researchers are developing more efficient SCR catalysts that can reduce emissions at lower temperatures.

- Enhanced Sensors: Advanced NOx sensors provide more accurate and reliable monitoring of nitrogen oxide levels.

13.2. Integration with Vehicle Systems

- Seamless Integration: Adblue systems are becoming more seamlessly integrated with vehicle systems, improving overall performance and efficiency.

- Remote Monitoring: Advanced telematics systems allow for remote monitoring of Adblue system performance, enabling proactive maintenance and repairs.

13.3. Alternative Emission Reduction Technologies

- Electric Vehicles: The rise of electric vehicles may eventually reduce the reliance on Adblue systems in the long term.

- Hybrid Systems: Hybrid systems that combine diesel and electric power may offer alternative emission reduction solutions.

14. Frequently Asked Questions (FAQ)

1. What is Adblue and why is it important?

Adblue, also known as Diesel Exhaust Fluid (DEF), is a solution used in diesel vehicles to reduce nitrogen oxide (NOx) emissions. It’s crucial for meeting environmental regulations and improving air quality.

2. How does the Adblue system work in a Mercedes Benz Sprinter?

The Adblue system injects DEF into the exhaust stream, where it reacts with NOx in the catalytic converter, converting them into harmless nitrogen and water.

3. What are the common issues with the Mercedes Benz Sprinter Adblue tank?

Common issues include DEF level sensor problems, DEF pump failure, DEF injector clogging, Adblue tank heater malfunction, and NOx sensor failure.

4. How can I diagnose Adblue tank problems?

Use a diagnostic scan tool to read fault codes, perform visual inspections, test Adblue quality, and check for clogged components.

5. How do I choose the right Adblue fluid for my Sprinter?

Select DEF that meets ISO 22241 standards, ensuring it has a urea concentration of 32.5% and is free from contaminants.

6. What maintenance is required for the Adblue system?

Regular maintenance includes checking DEF levels, inspecting for leaks, replacing the DEF filter, cleaning the injector, and monitoring NOx sensors.

7. Can I modify or upgrade my Adblue system?

While upgrades can improve efficiency, consider warranty issues, compliance with regulations, and compatibility with your vehicle model.

8. What are the legal and environmental considerations for Adblue systems?

Ensure compliance with emission regulations like EPA and Euro standards, and dispose of used DEF and components responsibly.

9. How can CARDIAGTECH.NET help with Adblue system maintenance?

CARDIAGTECH.NET offers diagnostic tools, replacement parts, and expert advice to help you maintain your Mercedes Benz Sprinter Adblue system.

10. What should I do if I encounter a fault code related to the Adblue tank?

Use a diagnostic tool to read and interpret the fault code, consult the service manual for troubleshooting steps, and clear the code after addressing the issue.

Maintaining your Mercedes Benz Sprinter Adblue tank is essential for ensuring optimal performance, reducing emissions, and complying with environmental regulations. By understanding the system, diagnosing problems accurately, and performing regular maintenance, you can keep your Sprinter running smoothly and efficiently. CARDIAGTECH.NET is your trusted partner for all your Adblue system needs, offering high-quality diagnostic tools, replacement parts, and expert support. Don’t let Adblue system issues slow you down—contact CARDIAGTECH.NET at 276 Reock St, City of Orange, NJ 07050, United States, or call us on Whatsapp at +1 (641) 206-8880. Visit CARDIAGTECH.NET today and experience the difference!