Adblue Malfunction Mercedes Sprinter can be frustrating, leading to limp mode and costly repairs. CARDIAGTECH.NET provides the tools and expertise to help you diagnose and resolve these issues efficiently. Learn about common causes, troubleshooting steps, and solutions for Adblue system problems, ensuring your Mercedes Sprinter stays on the road with optimal performance.

Contents

- 1. Understanding the Adblue System in Your Mercedes Sprinter

- 1.1. What is Adblue and Why is it Important?

- 1.2. Key Components of the Adblue System

- 1.3. How the Adblue System Works in a Mercedes Sprinter

- 2. Common Symptoms of Adblue Malfunction in Mercedes Sprinters

- 2.1. Warning Lights and Messages on the Dashboard

- 2.2. Limp Mode Activation

- 2.3. Engine Start Problems

- 2.4. Increased Fuel Consumption

- 2.5. Error Codes Related to the Adblue System

- 3. Potential Causes of Adblue Malfunction in Mercedes Sprinters

- 3.1. Low Adblue Level

- 3.2. Contaminated Adblue

- 3.3. Faulty Adblue Injector

- 3.4. Defective NOx Sensors

- 3.5. Adblue Pump Failure

- 3.6. Wiring and Electrical Issues

- 3.7. Clogged or Damaged SCR Catalytic Converter

- 4. Step-by-Step Guide to Diagnosing Adblue Malfunction

- 4.1. Checking Adblue Level and Quality

- 4.2. Using a Diagnostic Scanner to Read Error Codes

- 4.3. Inspecting the Adblue Injector

- 4.4. Testing the NOx Sensors

- 4.5. Checking the Adblue Pump

- 4.6. Inspecting Wiring and Connections

- 5. Solutions for Common Adblue Malfunctions

- 5.1. Refilling or Replacing Adblue

- 5.2. Cleaning or Replacing the Adblue Injector

- 5.3. Replacing Faulty NOx Sensors

- 5.4. Repairing or Replacing the Adblue Pump

- 5.5. Fixing Wiring and Electrical Issues

- 5.6. Cleaning or Replacing the SCR Catalytic Converter

- 6. Essential Tools and Equipment for Adblue System Repair

- 6.1. Diagnostic Scanner

- 6.2. Multimeter

- 6.3. Socket Set and Wrenches

- 6.4. Adblue Refractometer

- 6.5. Pressure Tester

- 6.6. Wiring Repair Kit

- 7. Preventive Maintenance Tips to Avoid Adblue Malfunctions

- 7.1. Regularly Check and Refill Adblue Level

- 7.2. Use High-Quality Adblue

- 7.3. Avoid Contamination of Adblue

- 7.4. Inspect and Clean Adblue Injector Regularly

- 7.5. Monitor NOx Sensor Readings

- 7.6. Perform Regular System Checks

- 7.7. Follow Recommended Service Intervals

- 8. Understanding Mercedes-Benz Adblue Specifications

- 8.1. Adblue Fluid Standards

- 8.2. Correct Adblue Fluid Type

- 8.3. Adblue Capacity for Mercedes Sprinter Models

- 8.4. Factors Affecting Adblue Consumption

- 8.5. Monitoring Adblue Levels

- 9. Troubleshooting Adblue System Sensor Issues

- 9.1. Identifying Common Sensor Faults

- 9.2. Testing Sensor Functionality

- 9.3. Replacing Defective Sensors

- 9.4. Calibrating Sensors After Replacement

- 10. Diagnosing and Resolving Adblue Pump and Injector Issues

- 10.1. Common Adblue Pump Problems

- 10.2. Testing Adblue Pump Performance

- 10.3. Common Adblue Injector Problems

- 10.4. Testing Adblue Injector Functionality

- 10.5. Cleaning or Replacing the Pump and Injector

- 10.6. Ensuring Proper Adblue Delivery

- 11. Addressing Adblue Heater Issues in Cold Climates

- 11.1. Understanding the Role of the Adblue Heater

- 11.2. Common Adblue Heater Problems

- 11.3. Testing Adblue Heater Functionality

- 11.4. Replacing a Faulty Adblue Heater

- 11.5. Preventing Future Heater Issues

- 12. Using CARDIAGTECH.NET for Your Adblue System Needs

- 12.1. Wide Range of Diagnostic Scanners

- 12.2. High-Quality Replacement Parts

- 12.3. Expert Technical Support

- 12.4. Competitive Pricing

- 12.5. Fast Shipping

- 12.6. Customer Satisfaction Guarantee

- 13. Advanced Diagnostic Techniques for Complex Adblue Issues

- 13.1. Performing Component-Level Testing

- 13.2. Analyzing Wiring Diagrams

- 13.3. Using a Smoke Machine to Detect Leaks

- 13.4. Performing Dynamic Testing

- 13.5. Consulting with Experts

- 14. Cost-Effective Strategies for Adblue System Maintenance

- 14.1. DIY Adblue Refills

- 14.2. Regular Cleaning of Components

- 14.3. Monitoring Fuel Efficiency

- 14.4. Purchasing Quality Parts

- 14.5. Taking Advantage of Warranties

- 14.6. Performing Preventive Maintenance

- 15. The Future of Adblue Technology in Mercedes-Benz Vehicles

- 15.1. Integration with Hybrid and Electric Vehicles

- 15.2. Advanced Monitoring and Control Systems

- 15.3. Use of Alternative Reductants

- 15.4. Improved Sensor Technology

- 15.5. Self-Diagnostic Capabilities

- 16. Case Studies: Real-World Adblue Malfunction Scenarios

- 16.1. Case Study 1: Clogged Adblue Injector

- 16.2. Case Study 2: Faulty NOx Sensor

- 16.3. Case Study 3: Adblue Pump Failure

- 16.4. Case Study 4: Adblue Heater Failure

- 17. Frequently Asked Questions (FAQs) About Adblue Malfunctions

- 17.1. What is Adblue and why is it necessary?

- 17.2. How do I know if my Adblue system is malfunctioning?

- 17.3. Can I drive my Mercedes Sprinter with an Adblue malfunction?

- 17.4. How often should I refill my Adblue tank?

- 17.5. What happens if I run out of Adblue?

- 17.6. Can I use any type of Adblue in my Mercedes Sprinter?

- 17.7. How do I check the Adblue level in my Mercedes Sprinter?

- 17.8. What tools do I need to diagnose an Adblue malfunction?

- 17.9. Can I repair an Adblue system myself?

- 17.10. Where can I find replacement parts for my Adblue system?

1. Understanding the Adblue System in Your Mercedes Sprinter

The Adblue system, also known as the Selective Catalytic Reduction (SCR) system, is crucial for reducing harmful nitrogen oxide (NOx) emissions from your Mercedes Sprinter. It works by injecting Adblue, a urea-based solution, into the exhaust stream. This reacts with the NOx in the catalytic converter, converting it into harmless nitrogen and water. A properly functioning Adblue system ensures your vehicle meets stringent emissions standards and avoids performance issues.

1.1. What is Adblue and Why is it Important?

Adblue is a non-toxic, odorless, and colorless solution of urea in demineralized water. It’s essential for modern diesel engines to meet Euro 6 emissions standards and is integral to the SCR system’s operation. Using Adblue helps reduce NOx emissions by up to 85%, contributing to cleaner air and environmental protection.

1.2. Key Components of the Adblue System

The Adblue system consists of several key components, each playing a vital role:

- Adblue Tank: Stores the Adblue solution. Capacities vary, but typically range from 5 to 30 liters.

- Adblue Pump: Delivers Adblue from the tank to the injector. It maintains the correct pressure for efficient injection.

- Adblue Injector: Sprays Adblue into the exhaust stream. Precise injection is crucial for optimal NOx reduction.

- NOx Sensors: Monitors the levels of NOx in the exhaust. These sensors provide feedback to the engine control unit (ECU).

- SCR Catalytic Converter: Facilitates the chemical reaction between Adblue and NOx.

- Engine Control Unit (ECU): Manages the entire Adblue system based on sensor data.

1.3. How the Adblue System Works in a Mercedes Sprinter

The Adblue system in your Mercedes Sprinter operates in a closed-loop manner. The ECU receives data from the NOx sensors, determining the amount of Adblue needed to reduce NOx emissions. The Adblue pump then delivers the solution to the injector, which sprays it into the exhaust stream before it enters the SCR catalytic converter. Here, the chemical reaction occurs, converting NOx into nitrogen and water. The NOx sensors continue to monitor emissions levels, providing real-time feedback to the ECU to adjust the injection rate as needed. This ensures optimal performance and compliance with emissions regulations.

2. Common Symptoms of Adblue Malfunction in Mercedes Sprinters

Recognizing the symptoms of an Adblue malfunction early can save you time and money on repairs. Here are some common signs to watch out for in your Mercedes Sprinter:

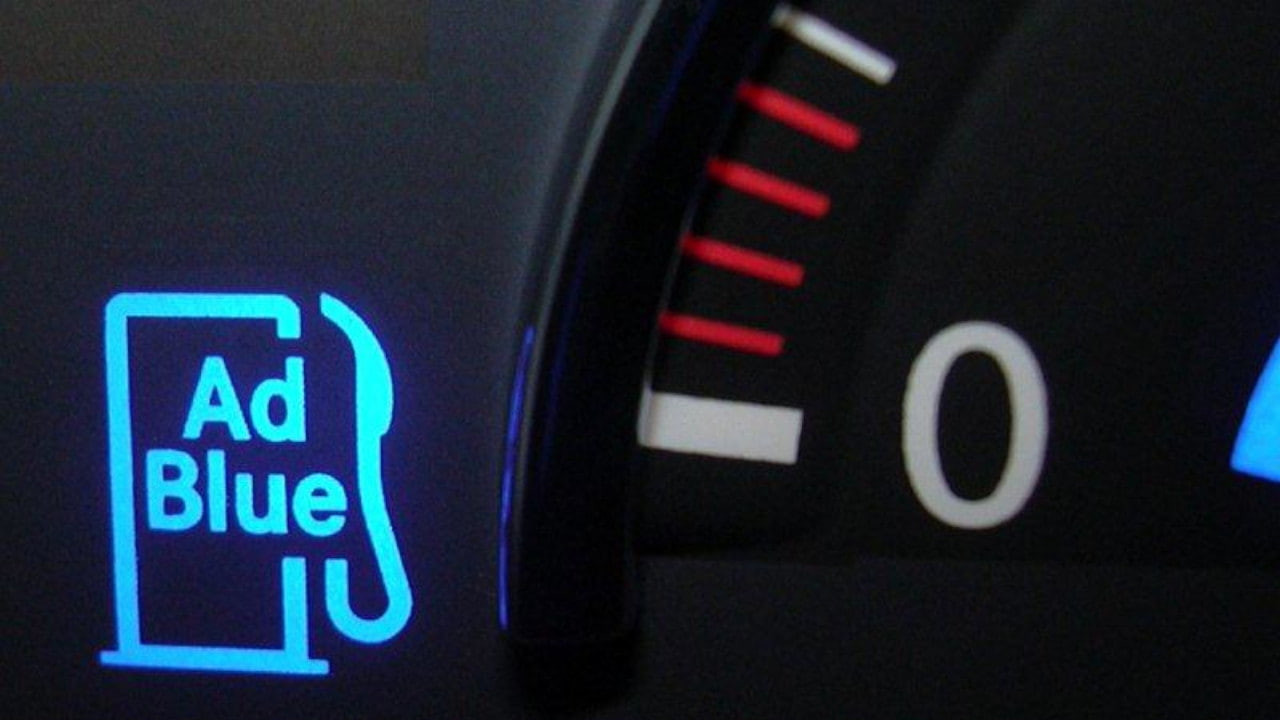

2.1. Warning Lights and Messages on the Dashboard

One of the first indicators of an Adblue issue is a warning light on your dashboard. This could be a general warning light or a specific Adblue warning symbol. Accompanying messages might include “Check Adblue Level,” “Adblue Malfunction,” or “Engine Will Not Start in XXX Miles.” These warnings are designed to alert you to potential problems before they escalate.

2.2. Limp Mode Activation

If the Adblue system detects a significant fault, your Mercedes Sprinter may enter limp mode. This is a safety feature that limits engine power and speed to prevent further damage. Limp mode can severely restrict your vehicle’s performance, making it difficult to drive and potentially unsafe in certain situations.

2.3. Engine Start Problems

In severe cases of Adblue malfunction, your Mercedes Sprinter may refuse to start. This is often a result of the system detecting critically high emissions levels or a complete failure of the Adblue system. The vehicle’s ECU will prevent the engine from starting to avoid further environmental damage.

2.4. Increased Fuel Consumption

A malfunctioning Adblue system can lead to increased fuel consumption. When the system isn’t operating correctly, the engine may compensate by using more fuel to maintain performance. This can result in higher running costs and reduced fuel efficiency.

2.5. Error Codes Related to the Adblue System

Error codes provide valuable information for diagnosing Adblue system issues. Common codes include:

- P20E8: Reductant Pressure Too Low

- P204F: Reductant System Performance

- P20BA: Reductant Heater “A” Control Circuit/Open

- P20BD: Reductant Heater “A” Control Circuit Low

- P20BE: Reductant Heater “A” Control Circuit High

These codes can be read using a diagnostic scanner, such as those available at CARDIAGTECH.NET, helping you pinpoint the specific problem area.

3. Potential Causes of Adblue Malfunction in Mercedes Sprinters

Understanding the potential causes of Adblue malfunctions can help you troubleshoot and resolve the issue more effectively. Here are some common reasons why your Mercedes Sprinter’s Adblue system might be failing:

3.1. Low Adblue Level

The most straightforward cause is simply a low Adblue level in the tank. The system requires an adequate supply of Adblue to function correctly. Regularly check the Adblue level and refill as needed.

3.2. Contaminated Adblue

Contaminated Adblue can cause significant problems. If the Adblue solution is mixed with other fluids or contains debris, it can clog the injector and damage the pump. Always use high-quality, certified Adblue from a reputable source.

3.3. Faulty Adblue Injector

The Adblue injector can become clogged or fail over time. This prevents the proper amount of Adblue from being injected into the exhaust stream, leading to increased emissions and system errors.

3.4. Defective NOx Sensors

NOx sensors are critical for monitoring emissions levels and providing feedback to the ECU. If these sensors are faulty, they can provide incorrect data, causing the system to malfunction.

3.5. Adblue Pump Failure

The Adblue pump is responsible for delivering the solution from the tank to the injector. A failing pump can result in insufficient Adblue delivery, leading to system errors and performance issues.

3.6. Wiring and Electrical Issues

Electrical problems, such as damaged wiring, corroded connectors, or blown fuses, can disrupt the Adblue system’s operation. These issues can prevent components from receiving power or transmitting data correctly.

3.7. Clogged or Damaged SCR Catalytic Converter

A clogged or damaged SCR catalytic converter can reduce the system’s efficiency. This can result in higher emissions levels and trigger warning lights.

4. Step-by-Step Guide to Diagnosing Adblue Malfunction

Diagnosing an Adblue malfunction requires a systematic approach. Here’s a step-by-step guide to help you identify the problem:

4.1. Checking Adblue Level and Quality

- Check the Adblue Level: Use the vehicle’s display or a dipstick to check the Adblue level in the tank. Refill if necessary, ensuring you use the correct type of Adblue.

- Inspect the Adblue Quality: If possible, take a sample of the Adblue and check for contamination. Look for any signs of debris, discoloration, or unusual odors.

4.2. Using a Diagnostic Scanner to Read Error Codes

- Connect the Scanner: Plug a diagnostic scanner into the OBD-II port of your Mercedes Sprinter. CARDIAGTECH.NET offers a range of high-quality scanners suitable for this task.

- Read Error Codes: Turn on the ignition and follow the scanner’s instructions to read the error codes stored in the ECU.

- Record the Codes: Write down all the error codes and their descriptions. This information will be crucial for further troubleshooting.

4.3. Inspecting the Adblue Injector

- Locate the Injector: Find the Adblue injector in the exhaust system, usually located before the SCR catalytic converter.

- Check for Clogs: Inspect the injector nozzle for any signs of clogging or buildup.

- Test the Injector: Use a multimeter to check the injector’s electrical resistance. Refer to your vehicle’s service manual for the correct resistance values.

4.4. Testing the NOx Sensors

- Locate the Sensors: Identify the NOx sensors in the exhaust system. There are typically two sensors: one before and one after the SCR catalytic converter.

- Check for Damage: Inspect the sensors for any physical damage or corrosion.

- Test the Sensors: Use a diagnostic scanner to monitor the NOx sensor readings. Compare the readings from both sensors to see if they are within the expected range.

4.5. Checking the Adblue Pump

- Locate the Pump: Find the Adblue pump, usually located near the Adblue tank.

- Check for Power: Use a multimeter to ensure the pump is receiving power.

- Test the Pump: Use a diagnostic scanner to activate the pump and check its operation. Listen for any unusual noises or vibrations.

4.6. Inspecting Wiring and Connections

- Visually Inspect: Check all wiring and connectors related to the Adblue system for any signs of damage, corrosion, or loose connections.

- Test for Continuity: Use a multimeter to test the continuity of the wiring. Refer to your vehicle’s service manual for wiring diagrams and testing procedures.

5. Solutions for Common Adblue Malfunctions

Once you’ve diagnosed the Adblue malfunction, you can start implementing solutions. Here are some common fixes for different issues:

5.1. Refilling or Replacing Adblue

- Refilling Adblue: If the Adblue level is low, simply refill the tank with high-quality, certified Adblue.

- Replacing Contaminated Adblue: If the Adblue is contaminated, drain the tank and refill it with fresh Adblue. Clean the tank and any associated components to remove any residual contamination.

5.2. Cleaning or Replacing the Adblue Injector

- Cleaning the Injector: If the injector is clogged, you can try cleaning it. Remove the injector and soak it in a cleaning solution designed for Adblue systems. Use a soft brush to remove any buildup.

- Replacing the Injector: If cleaning doesn’t resolve the issue, you may need to replace the injector. Ensure you purchase a genuine or high-quality aftermarket injector that is compatible with your Mercedes Sprinter.

5.3. Replacing Faulty NOx Sensors

If the NOx sensors are faulty, they need to be replaced. Purchase new sensors from a reputable supplier and follow the manufacturer’s instructions for installation.

5.4. Repairing or Replacing the Adblue Pump

- Repairing the Pump: In some cases, the Adblue pump can be repaired. Check for any obvious damage or worn parts and replace them as needed.

- Replacing the Pump: If the pump is severely damaged or cannot be repaired, it needs to be replaced. Ensure you purchase a compatible pump and follow the manufacturer’s instructions for installation.

5.5. Fixing Wiring and Electrical Issues

- Repairing Wiring: Repair any damaged wiring by splicing in new sections of wire and using heat-shrink tubing to protect the connections.

- Replacing Connectors: Replace any corroded or damaged connectors with new ones.

- Checking Fuses: Check all fuses related to the Adblue system and replace any blown fuses with the correct amperage.

5.6. Cleaning or Replacing the SCR Catalytic Converter

- Cleaning the Converter: In some cases, the SCR catalytic converter can be cleaned. Remove the converter and soak it in a cleaning solution designed for catalytic converters. Use a pressure washer to remove any buildup.

- Replacing the Converter: If cleaning doesn’t resolve the issue, you may need to replace the converter. Ensure you purchase a genuine or high-quality aftermarket converter that is compatible with your Mercedes Sprinter.

6. Essential Tools and Equipment for Adblue System Repair

Having the right tools and equipment is essential for effectively diagnosing and repairing Adblue system malfunctions. Here are some must-have items:

6.1. Diagnostic Scanner

A diagnostic scanner is crucial for reading error codes and monitoring sensor data. CARDIAGTECH.NET offers a variety of scanners suitable for Mercedes Sprinters.

6.2. Multimeter

A multimeter is essential for testing electrical components, such as wiring, connectors, and sensors.

6.3. Socket Set and Wrenches

A comprehensive socket set and wrench set are necessary for removing and installing various components of the Adblue system.

6.4. Adblue Refractometer

An Adblue refractometer is used to measure the concentration of urea in the Adblue solution. This helps ensure the Adblue is of the correct quality.

6.5. Pressure Tester

A pressure tester can be used to check the pressure of the Adblue pump.

6.6. Wiring Repair Kit

A wiring repair kit includes all the necessary tools and materials for repairing damaged wiring and connectors.

| Tool | Description | Approximate Cost | Benefits |

|---|---|---|---|

| Diagnostic Scanner | Reads error codes, monitors sensor data | $100 – $500 | Quickly identifies issues, saves time and money |

| Multimeter | Tests electrical components | $20 – $100 | Ensures proper function of wiring, sensors, and pumps |

| Socket & Wrench Set | Removes and installs components | $50 – $200 | Allows for efficient and safe removal and installation of parts |

| Adblue Refractometer | Measures urea concentration | $30 – $100 | Verifies Adblue quality, prevents damage from contaminated solution |

| Pressure Tester | Checks Adblue pump pressure | $40 – $150 | Ensures pump is functioning correctly, prevents under or over-delivery of Adblue |

| Wiring Repair Kit | Repairs damaged wiring and connectors | $20 – $50 | Fixes electrical issues, restores proper function of the Adblue system |

7. Preventive Maintenance Tips to Avoid Adblue Malfunctions

Preventive maintenance is key to avoiding costly Adblue system repairs. Here are some tips to keep your Mercedes Sprinter’s Adblue system in top condition:

7.1. Regularly Check and Refill Adblue Level

Make it a habit to check the Adblue level regularly and refill as needed. This ensures the system always has an adequate supply of Adblue.

7.2. Use High-Quality Adblue

Always use high-quality, certified Adblue from a reputable source. This helps prevent contamination and ensures the system operates efficiently.

7.3. Avoid Contamination of Adblue

Take precautions to avoid contaminating the Adblue solution. Use a clean funnel when refilling and store Adblue in a clean, sealed container.

7.4. Inspect and Clean Adblue Injector Regularly

Inspect the Adblue injector regularly for any signs of clogging or buildup. Clean the injector as needed to ensure proper operation.

7.5. Monitor NOx Sensor Readings

Use a diagnostic scanner to monitor the NOx sensor readings periodically. This can help you detect any issues early on.

7.6. Perform Regular System Checks

Perform regular system checks using a diagnostic scanner to identify any potential problems before they escalate.

7.7. Follow Recommended Service Intervals

Follow the recommended service intervals for your Mercedes Sprinter, including any maintenance related to the Adblue system.

8. Understanding Mercedes-Benz Adblue Specifications

To ensure your Mercedes Sprinter’s Adblue system functions optimally, it’s essential to understand the correct specifications for Adblue fluid. Here’s what you need to know:

8.1. Adblue Fluid Standards

Adblue, also known as Diesel Exhaust Fluid (DEF), must meet the ISO 22241 standard. This standard ensures the fluid has the correct concentration of urea (32.5%) and is free from contaminants that could damage the SCR system. Always look for Adblue products that explicitly state they meet the ISO 22241 standard.

8.2. Correct Adblue Fluid Type

Using the correct type of Adblue is crucial for your Mercedes Sprinter. Ensure that the Adblue you purchase is specifically designed for diesel engines and meets the ISO 22241 standard. Avoid using any other type of fluid, as it could damage the SCR system.

8.3. Adblue Capacity for Mercedes Sprinter Models

The Adblue tank capacity can vary depending on the specific Mercedes Sprinter model. Here are some approximate capacities:

| Model | Adblue Tank Capacity |

|---|---|

| Sprinter 2500 | 22 Liters |

| Sprinter 3500 | 22 Liters |

| Sprinter 4500 | 22 Liters |

Always refer to your vehicle’s owner’s manual for the exact Adblue tank capacity.

8.4. Factors Affecting Adblue Consumption

Adblue consumption can vary based on several factors:

- Driving Style: Aggressive driving and frequent acceleration can increase Adblue consumption.

- Load: Carrying heavy loads can also increase consumption.

- Environmental Conditions: Extreme temperatures can affect the efficiency of the SCR system, leading to higher Adblue usage.

- Engine Condition: A poorly maintained engine can lead to increased emissions and higher Adblue consumption.

8.5. Monitoring Adblue Levels

Regularly monitor the Adblue level in your Mercedes Sprinter. The vehicle’s dashboard display will typically provide a warning when the Adblue level is low. Ignoring these warnings can lead to the vehicle entering limp mode or refusing to start.

9. Troubleshooting Adblue System Sensor Issues

Adblue system sensors play a critical role in monitoring and controlling emissions. Issues with these sensors can lead to malfunctions. Here’s how to troubleshoot common sensor problems:

9.1. Identifying Common Sensor Faults

Several sensors can cause Adblue system issues:

- NOx Sensors: These sensors measure the levels of nitrogen oxides in the exhaust gas. Faulty NOx sensors can provide incorrect readings, leading to improper Adblue injection.

- Temperature Sensors: These sensors monitor the temperature of the exhaust gas and the SCR catalytic converter. Incorrect temperature readings can affect the efficiency of the SCR system.

- Level Sensors: These sensors monitor the level of Adblue in the tank. Faulty level sensors can provide incorrect readings, leading to premature warnings or failure to detect low Adblue levels.

- Pressure Sensors: These sensors monitor the pressure of the Adblue being injected into the exhaust stream. Faulty pressure sensors can affect the proper amount of Adblue being injected.

9.2. Testing Sensor Functionality

To test sensor functionality, you will need a diagnostic scanner and a multimeter. Here’s a general process:

- Read Error Codes: Use a diagnostic scanner to read any error codes related to the sensors.

- Check Sensor Readings: Use the scanner to monitor the real-time readings from the sensors. Compare these readings to the expected values.

- Test Sensor Wiring: Use a multimeter to check the continuity and voltage of the sensor wiring. Ensure there are no shorts or open circuits.

- Inspect Sensor Connections: Check the sensor connections for corrosion or damage. Clean or replace the connectors as needed.

9.3. Replacing Defective Sensors

If a sensor is found to be defective, it will need to be replaced. Here are some general steps:

- Disconnect the Battery: Disconnect the negative terminal of the battery to prevent electrical shorts.

- Locate the Sensor: Identify the location of the defective sensor.

- Disconnect the Sensor: Disconnect the electrical connector from the sensor.

- Remove the Sensor: Remove the sensor from its mounting location.

- Install the New Sensor: Install the new sensor in the same location.

- Connect the Sensor: Connect the electrical connector to the sensor.

- Reconnect the Battery: Reconnect the negative terminal of the battery.

- Clear Error Codes: Use a diagnostic scanner to clear any error codes related to the sensor.

9.4. Calibrating Sensors After Replacement

In some cases, sensors may need to be calibrated after replacement. Refer to your vehicle’s service manual for specific calibration procedures. A diagnostic scanner may be required to perform the calibration.

10. Diagnosing and Resolving Adblue Pump and Injector Issues

The Adblue pump and injector are critical components of the SCR system. Issues with these components can lead to significant malfunctions. Here’s how to diagnose and resolve common problems:

10.1. Common Adblue Pump Problems

- Pump Failure: The pump may fail to deliver Adblue due to mechanical or electrical issues.

- Low Pressure: The pump may not be able to generate enough pressure to inject Adblue properly.

- Leaks: The pump may develop leaks, leading to a loss of Adblue.

- Clogging: The pump may become clogged with debris, preventing proper operation.

10.2. Testing Adblue Pump Performance

- Check Power Supply: Use a multimeter to ensure the pump is receiving power.

- Inspect Wiring: Check the pump wiring for damage or corrosion.

- Monitor Pressure: Use a diagnostic scanner to monitor the Adblue pressure. Compare the pressure to the specified values.

- Listen for Operation: Listen for the pump to operate when the engine is running. If the pump is not running, it may be faulty.

10.3. Common Adblue Injector Problems

- Clogging: The injector may become clogged with debris, preventing proper Adblue injection.

- Leaks: The injector may develop leaks, leading to a loss of Adblue.

- Failure to Inject: The injector may fail to inject Adblue due to electrical or mechanical issues.

10.4. Testing Adblue Injector Functionality

- Inspect for Clogging: Visually inspect the injector for any signs of clogging or debris.

- Check Wiring: Check the injector wiring for damage or corrosion.

- Test Resistance: Use a multimeter to measure the resistance of the injector. Compare the resistance to the specified values.

- Activate Injector: Use a diagnostic scanner to activate the injector and listen for it to click. If the injector does not click, it may be faulty.

10.5. Cleaning or Replacing the Pump and Injector

- Cleaning: Clean the pump and injector with a cleaning solution designed for Adblue systems. Use a soft brush to remove any buildup.

- Replacing: If cleaning does not resolve the issue, replace the pump or injector with a new one. Ensure the replacement part is compatible with your Mercedes Sprinter.

10.6. Ensuring Proper Adblue Delivery

After repairing or replacing the pump or injector, ensure proper Adblue delivery. Monitor the NOx sensor readings and Adblue consumption to verify that the system is functioning correctly.

11. Addressing Adblue Heater Issues in Cold Climates

In cold climates, the Adblue system can experience issues due to freezing. The Adblue heater is designed to prevent the fluid from freezing. Here’s how to address common heater problems:

11.1. Understanding the Role of the Adblue Heater

The Adblue heater is responsible for keeping the Adblue fluid warm enough to prevent freezing. This is crucial for the proper operation of the SCR system in cold weather.

11.2. Common Adblue Heater Problems

- Heater Failure: The heater may fail due to electrical or mechanical issues.

- Wiring Issues: The heater wiring may become damaged or corroded.

- Fuse Problems: The heater fuse may blow, preventing the heater from operating.

11.3. Testing Adblue Heater Functionality

- Check Fuse: Check the heater fuse and replace it if necessary.

- Inspect Wiring: Check the heater wiring for damage or corrosion.

- Test Voltage: Use a multimeter to check the voltage at the heater connector.

- Monitor Temperature: Use a diagnostic scanner to monitor the temperature of the Adblue fluid. If the temperature is not increasing, the heater may be faulty.

11.4. Replacing a Faulty Adblue Heater

- Disconnect the Battery: Disconnect the negative terminal of the battery to prevent electrical shorts.

- Locate the Heater: Identify the location of the Adblue heater.

- Disconnect the Heater: Disconnect the electrical connector from the heater.

- Remove the Heater: Remove the heater from its mounting location.

- Install the New Heater: Install the new heater in the same location.

- Connect the Heater: Connect the electrical connector to the heater.

- Reconnect the Battery: Reconnect the negative terminal of the battery.

- Clear Error Codes: Use a diagnostic scanner to clear any error codes related to the heater.

11.5. Preventing Future Heater Issues

- Regular Inspections: Inspect the heater wiring and connections regularly for damage or corrosion.

- Use Proper Adblue: Use high-quality Adblue to prevent clogging and ensure proper heater operation.

- Monitor System Performance: Monitor the Adblue system performance to detect any heater issues early on.

12. Using CARDIAGTECH.NET for Your Adblue System Needs

CARDIAGTECH.NET offers a comprehensive range of tools and equipment to help you diagnose and repair Adblue system malfunctions in your Mercedes Sprinter. Here are some ways we can assist you:

12.1. Wide Range of Diagnostic Scanners

We offer a variety of diagnostic scanners suitable for Mercedes Sprinters, allowing you to read error codes, monitor sensor data, and perform system tests.

12.2. High-Quality Replacement Parts

We provide high-quality replacement parts for the Adblue system, including pumps, injectors, sensors, and heaters.

12.3. Expert Technical Support

Our team of expert technicians can provide you with technical support and guidance to help you diagnose and resolve Adblue system issues.

12.4. Competitive Pricing

We offer competitive pricing on all our products and services, ensuring you get the best value for your money.

12.5. Fast Shipping

We offer fast shipping on all orders, so you can get the parts and tools you need quickly.

12.6. Customer Satisfaction Guarantee

We are committed to customer satisfaction and offer a guarantee on all our products and services.

13. Advanced Diagnostic Techniques for Complex Adblue Issues

For complex Adblue issues that are not easily resolved, advanced diagnostic techniques may be necessary. Here are some strategies:

13.1. Performing Component-Level Testing

Component-level testing involves testing individual components of the Adblue system to identify faults. This may require specialized tools and equipment, such as an oscilloscope or a signal generator.

13.2. Analyzing Wiring Diagrams

Analyzing wiring diagrams can help you identify potential electrical issues. Use the wiring diagrams to trace the circuits and check for continuity, voltage, and resistance.

13.3. Using a Smoke Machine to Detect Leaks

A smoke machine can be used to detect leaks in the Adblue system. Introduce smoke into the system and look for any signs of smoke escaping.

13.4. Performing Dynamic Testing

Dynamic testing involves testing the Adblue system while the engine is running. This can help you identify issues that only occur under certain conditions.

13.5. Consulting with Experts

If you are unable to resolve the Adblue issue, consult with a qualified technician or Adblue system expert. They may have the knowledge and experience to diagnose and repair the problem. Contact CARDIAGTECH.NET for expert support and guidance.

14. Cost-Effective Strategies for Adblue System Maintenance

Maintaining your Adblue system doesn’t have to break the bank. Here are some cost-effective strategies:

14.1. DIY Adblue Refills

Refilling Adblue yourself can save you money compared to having a mechanic do it. Purchase Adblue in bulk and refill the tank as needed.

14.2. Regular Cleaning of Components

Regularly cleaning components, such as the injector and pump, can prevent clogging and extend their lifespan.

14.3. Monitoring Fuel Efficiency

Monitoring your fuel efficiency can help you detect Adblue system issues early on. A decrease in fuel efficiency may indicate a problem with the system.

14.4. Purchasing Quality Parts

Purchasing quality parts, even if they are more expensive upfront, can save you money in the long run by reducing the risk of premature failure. CARDIAGTECH.NET offers a range of high-quality parts at competitive prices.

14.5. Taking Advantage of Warranties

Take advantage of warranties on Adblue system components. If a part fails within the warranty period, you may be able to get it replaced for free.

14.6. Performing Preventive Maintenance

Performing preventive maintenance, such as regularly checking the Adblue level and inspecting components, can help you avoid costly repairs.

15. The Future of Adblue Technology in Mercedes-Benz Vehicles

Adblue technology is constantly evolving. Here’s a look at the future of Adblue systems in Mercedes-Benz vehicles:

15.1. Integration with Hybrid and Electric Vehicles

Adblue technology may be integrated with hybrid and electric vehicles to further reduce emissions.

15.2. Advanced Monitoring and Control Systems

Advanced monitoring and control systems may be used to optimize Adblue injection and improve system efficiency.

15.3. Use of Alternative Reductants

Alternative reductants may be used in place of Adblue to reduce emissions.

15.4. Improved Sensor Technology

Improved sensor technology may be used to monitor emissions more accurately and provide better feedback to the control system.

15.5. Self-Diagnostic Capabilities

Adblue systems may be equipped with self-diagnostic capabilities to detect and resolve issues automatically.

16. Case Studies: Real-World Adblue Malfunction Scenarios

Examining real-world scenarios can provide valuable insights into diagnosing and resolving Adblue malfunctions:

16.1. Case Study 1: Clogged Adblue Injector

- Symptoms: Reduced engine performance, increased emissions, and an error code indicating a clogged injector.

- Diagnosis: Visual inspection revealed a clogged injector.

- Solution: The injector was removed and cleaned. After cleaning, the system functioned correctly.

16.2. Case Study 2: Faulty NOx Sensor

- Symptoms: Increased emissions, poor fuel efficiency, and an error code indicating a faulty NOx sensor.

- Diagnosis: The NOx sensor readings were outside the specified range.

- Solution: The faulty NOx sensor was replaced. After replacement, the system functioned correctly.

16.3. Case Study 3: Adblue Pump Failure

- Symptoms: No Adblue injection, reduced engine performance, and an error code indicating a pump failure.

- Diagnosis: The Adblue pump was not receiving power.

- Solution: The faulty Adblue pump was replaced. After replacement, the system functioned correctly.

16.4. Case Study 4: Adblue Heater Failure

- Symptoms: Adblue freezing in cold weather, reduced engine performance, and an error code indicating a heater failure.

- Diagnosis: The Adblue heater was not functioning.

- Solution: The faulty Adblue heater was replaced. After replacement, the system functioned correctly.

These case studies highlight the importance of proper diagnosis and repair techniques. With the right tools and knowledge, you can effectively resolve Adblue system malfunctions in your Mercedes Sprinter.

17. Frequently Asked Questions (FAQs) About Adblue Malfunctions

Here are some frequently asked questions about Adblue malfunctions in Mercedes Sprinters:

17.1. What is Adblue and why is it necessary?

Adblue is a urea-based solution used in diesel engines to reduce nitrogen oxide (NOx) emissions. It’s necessary to meet stringent emissions standards.

17.2. How do I know if my Adblue system is malfunctioning?

Common symptoms include warning lights on the dashboard, limp mode activation, engine start problems, and increased fuel consumption.

17.3. Can I drive my Mercedes Sprinter with an Adblue malfunction?

Driving with an Adblue malfunction can lead to reduced engine performance and potential damage to the system. It’s best to address the issue as soon as possible.

17.4. How often should I refill my Adblue tank?

The frequency of Adblue refills depends on driving conditions and vehicle usage. Check the Adblue level regularly and refill as needed.

17.5. What happens if I run out of Adblue?

If you run out of Adblue, your Mercedes Sprinter may enter limp mode or refuse to start.

17.6. Can I use any type of Adblue in my Mercedes Sprinter?

No, always use high-quality, certified Adblue that meets the ISO 22241 standard.

17.7. How do I check the Adblue level in my Mercedes Sprinter?

Use the vehicle’s display or a dipstick to check the Adblue level in the tank.

17.8. What tools do I need to diagnose an Adblue malfunction?

Essential tools include a diagnostic scanner, multimeter, socket set, and wrench set.

17.9. Can I repair an Adblue system myself?

Depending on the complexity of the issue, you may be able to repair the Adblue system yourself. However, some repairs may require specialized knowledge and equipment.

17.10. Where can I find replacement parts for my Adblue system?

You can find replacement parts at CARDIAGTECH.NET, which offers a wide range of high-quality parts for Adblue systems.

Experiencing Adblue malfunctions in your Mercedes Sprinter can be a headache, but you don’t have to face it alone. At CARDIAGTECH.NET, we understand the challenges you face as a technician or shop owner. The physical demands, constant need for updated knowledge, and pressure to deliver efficient, accurate repairs can be overwhelming.

That’s why we’re here to offer not just tools, but solutions tailored to your needs. Whether you’re a young tech starting out, an experienced mechanic looking for reliable equipment, or a shop manager focused on productivity, CARDIAGTECH.NET has something for you.

Imagine cutting down diagnostic time, improving repair accuracy, and saving money on costly mistakes. Our range of diagnostic scanners, multimeters, and specialized tools are designed to do just that. Plus, with our expert technical support, you’ll have the guidance you need to tackle even the most complex Adblue system issues.

Ready to elevate your repair game and provide top-notch service to your customers? Contact CARDIAGTECH.NET today.

Address: 276 Reock St, City of Orange, NJ 07050, United States

WhatsApp: +1 (641) 206-8880

Website: CARDIAGTECH.NET

Let us help you enhance your efficiency, increase your accuracy, and boost your shop’s reputation. Reach out now and let’s discuss how CARDIAGTECH.NET can be your partner in success.