How to Fix a Cassette Deck in Your Car: A Comprehensive Guide

Cassette decks, once a staple in car audio, are experiencing a resurgence in popularity, fueled by nostalgia and a love for analog sound. If you’re lucky enough to have a classic car with a cassette player or you’ve installed one for that retro vibe, you might encounter a common issue: a malfunctioning cassette deck. Often, the culprit is the humble belt. Like tires on your car, cassette deck belts wear out over time, leading to playback problems. This guide will walk you through understanding, diagnosing, and fixing belt-related issues in your car cassette deck, ensuring your favorite mixtapes can hit the road with you again.

Understanding the Role of Belts in Cassette Decks

Belts are fundamental to the operation of almost every cassette deck. They are the unsung heroes responsible for transferring power from the motor to various mechanical parts within the deck. Think of them as tiny drive belts, similar in principle to the serpentine belt in your car’s engine. The electric motor in a cassette deck doesn’t spin with perfectly smooth motion; it operates with minute pulsations. These subtle jerks need to be smoothed out to ensure consistent tape speed and sound quality. This is where the elasticity of the belt, combined with a flywheel, comes into play. The belt acts as a mechanical buffer, absorbing these micro-vibrations, while the flywheel, a weighted rotating component, further stabilizes the speed. Almost every cassette deck, barring a very rare Eumig model, incorporates a flywheel into its design.

Alt text: Open view of a basic GE cassette recorder mechanism, highlighting the motor pulley, flywheel, and belt path for illustrating single motor cassette deck design.

In basic cassette decks, like the GE shoe box recorder pictured above, a single motor transport system is common. One motor manages all functions – playing, fast forwarding, rewinding. While economical, this setup can be less precise due to the motor handling multiple tasks and potential speed fluctuations. In the image, you can see a whitish plastic pulley attached to the motor on the left. Following the belt, it loops around a larger metal pulley – the flywheel – which drives the capstan. The capstan is a crucial component we’ll discuss further when we delve into the tape head area. Finally, the belt connects to a black plastic pulley, which powers the hubs. The hubs are responsible for tape movement during fast forward and rewind operations. This single-motor, single-belt configuration is frequently found in portable cassette players and entry-level home decks, and often car cassette players due to cost considerations.

More sophisticated home decks, such as the Harmon Kardon model shown below, might still utilize a single motor for cost-effectiveness, but employ a heavier flywheel and a more robust motor to achieve higher performance and stability.

Alt text: Detailed view of a Harmon Kardon cassette deck mechanism focusing on the motor with visible speed adjustment hole and surrounding components.

Alt text: Wider shot of a Harmon Kardon cassette deck transport showcasing the belt routing and connection to the flywheel and other pulleys in a single motor system.

In the close-up image of the Harmon Kardon transport, you can see a small hole just below the number “12” on the motor. This is a speed adjustment port. By inserting a small flathead or Phillips screwdriver (depending on the motor type), you can fine-tune the motor speed. However, this adjustment is not a solution for a worn or loose belt, nor for a mechanism that is stiff due to old grease or dirt. Speed adjustment is intended for calibration using a specialized speed adjustment tape and a frequency counter. This process involves playing a test tape with a precisely recorded tone and adjusting the motor until the frequency counter displays the correct reading, ensuring accurate playback speed. Crucially, always use an insulated screwdriver for speed adjustments as some motors have electrical potential differences between internal parts and the motor casing.

Older car cassette decks, particularly top-loading models, sometimes used larger AC motors instead of the smaller DC motors common today. These AC motor decks generally lack speed adjustment features. If an AC motor deck plays slowly, the issue is almost certainly a slipping belt or a mechanism requiring cleaning and lubrication.

Higher-end car cassette decks, although less common, might incorporate multiple motors, each dedicated to specific functions like capstan drive, reel drive, and mechanism control. This multi-motor approach offers improved performance and reduced mechanical complexity for each motor.

Diagnosing Belt Problems in Your Car Cassette Deck

Several symptoms indicate belt issues in your car cassette deck:

- Slow Playback: This is the most common sign. A worn or stretched belt loses tension, causing slippage and slower tape speed. Music will sound sluggish and lower in pitch.

- Wow and Flutter: Inconsistent tape speed due to belt slippage or uneven wear can result in noticeable fluctuations in pitch, known as wow and flutter.

- Failure to Play or Eject: A broken belt will prevent the mechanism from engaging altogether. The deck might appear dead, failing to play, fast forward, rewind, or even eject the cassette.

- Squealing or Slipping Noises: As belts age, they can become hard and glazed, leading to squealing sounds as they slip on the pulleys.

- Weak Motor Sounds: You might hear the motor running, but the mechanism isn’t engaging properly, indicating a lack of belt tension.

How to Fix a Cassette Deck in Your Car: Belt Replacement

Replacing the belts in your car cassette deck is a manageable DIY task for those comfortable with basic electronics and mechanics. Here’s a step-by-step guide:

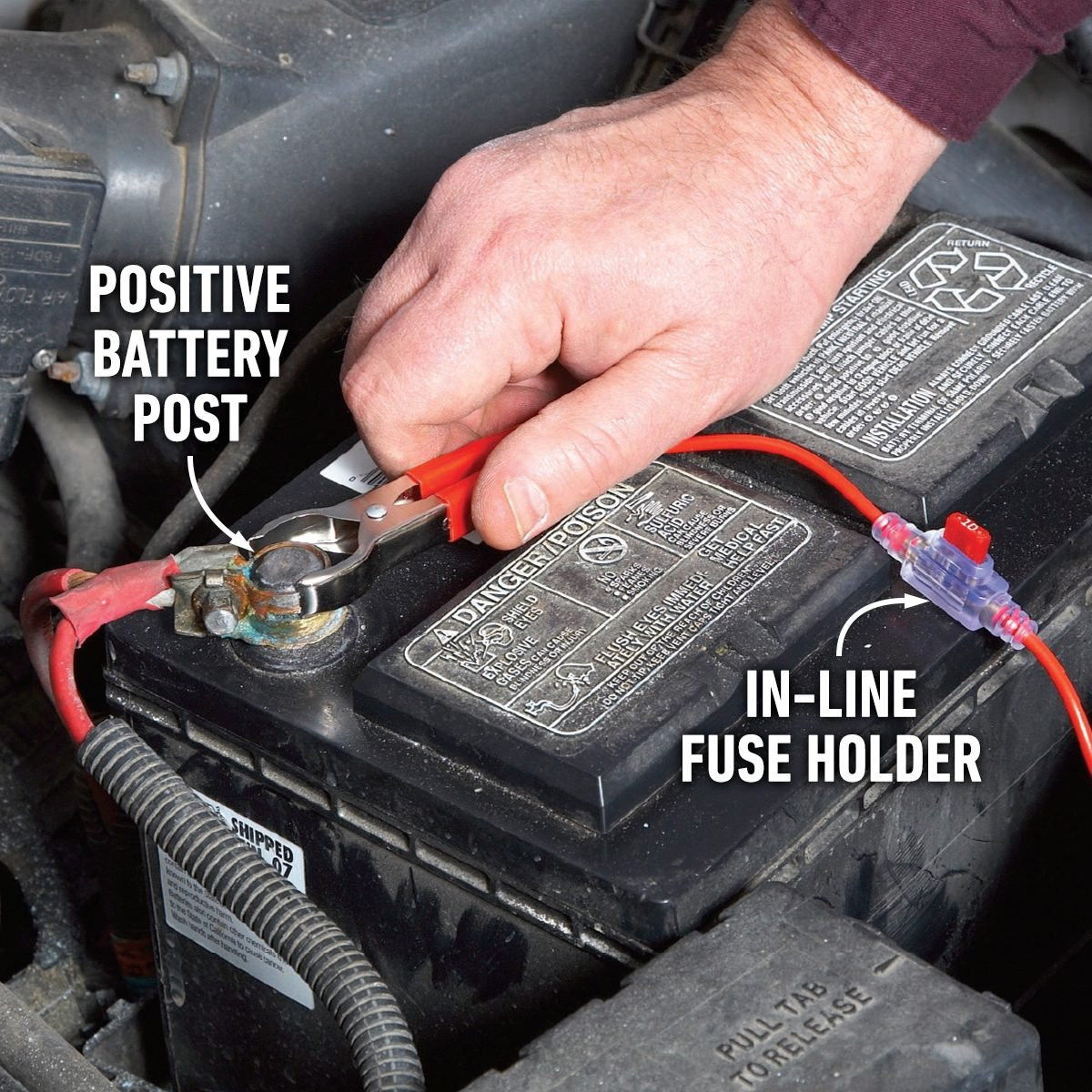

1. Safety First & Preparation:

- Disconnect Power: Before starting any work, completely disconnect your car battery to prevent electrical shorts and ensure safety.

- Remove the Cassette Deck: Carefully remove the cassette deck unit from your car’s dashboard. This usually involves removing trim panels and unscrewing mounting brackets. Consult your car’s repair manual or online guides specific to your vehicle model for detailed instructions.

- Work Area: Set up a clean, well-lit workspace. Use a soft cloth or anti-static mat to protect the deck and surrounding surfaces.

- Tools: Gather the necessary tools:

- Screwdrivers (Phillips and flathead, various sizes)

- Needle-nose pliers

- Tweezers

- Small container for screws

- Replacement belts (ensure you have the correct size and type – more on this below)

- Rubbing alcohol and cotton swabs for cleaning

- Optional: Belt hook tool (can be helpful for tricky belt placements)

- Optional: Camera or phone to take pictures as you disassemble (highly recommended!)

2. Accessing the Belts:

- Open the Cassette Deck: Carefully disassemble the cassette deck to access the transport mechanism where the belts are located. This typically involves removing the outer casing, faceplate, and possibly some internal panels. Take photos as you go to remember the order and placement of parts.

- Locate the Belts: Identify the belts. There will usually be one or more belts, often connecting the motor to the flywheel and other pulleys. They may be visibly worn, cracked, loose, or even broken.

3. Removing the Old Belts:

- Carefully Remove Old Belts: Use tweezers or needle-nose pliers to gently remove the old belts. Be careful not to damage any pulleys or plastic parts. Note the path and routing of each belt before removal; this is crucial for correct reinstallation. Again, photos are invaluable here.

4. Cleaning and Inspection:

- Clean Pulleys and Flywheel: Clean all pulleys and the flywheel with rubbing alcohol and cotton swabs. Remove any residue from the old belts. This ensures good grip for the new belts.

- Inspect Components: Inspect the pulleys, flywheel, capstan, and other mechanical parts for any damage, wear, or stiffness. Lubricate any sticky or stiff parts with a tiny amount of specialized electronic lubricant or light machine oil, if necessary.

5. Installing the New Belts:

- Install New Belts: Using your photos and notes as a guide, carefully install the new belts. This can sometimes be fiddly, especially getting belts around tight corners or behind components. A belt hook tool can be helpful. Ensure the belts are seated correctly in the grooves of the pulleys and are not twisted.

- Double Check Belt Routing: Re-verify that all belts are routed correctly and have the proper tension. They should be snug but not overly tight.

6. Reassembly and Testing:

- Reassemble the Cassette Deck: Carefully reassemble the cassette deck in reverse order of disassembly, using your photos as a guide. Ensure all screws are tightened properly, but don’t overtighten.

- Reconnect and Test: Carefully reinstall the cassette deck back into your car, reconnect the wiring, and reconnect the car battery. Test the cassette deck with a tape. Check for proper playback speed, sound quality, and all functions (play, fast forward, rewind, eject).

7. Fine Tuning (If Necessary):

- Speed Adjustment (If Applicable): If playback speed is still slightly off after belt replacement, you may need to perform a speed adjustment using the speed adjustment port on the motor, as described earlier, with a calibration tape and frequency counter for precise results. However, belt replacement usually resolves most speed issues.

Finding Replacement Belts

Obtaining the correct replacement belts is vital. Here’s how:

- Belt Kits: Search online for “cassette deck belt kit” or “car cassette deck belt kit” along with the make and model of your car or cassette deck unit. Many online retailers specialize in belts for vintage audio equipment.

- Belt Size Measurement: If you can’t find a kit, you might need to measure the old belts (if they are not broken beyond recognition). Measure the length and cross-section (width and thickness) of the belt. Online resources and belt manufacturers often have guides and charts to help identify belt sizes based on measurements.

- Universal Belt Assortments: As a last resort, universal belt assortments are available, containing a variety of belt sizes. You can try to find a belt that closely matches your needs, but it’s always best to get the exact size if possible for optimal performance and longevity.

Auto Stop and Auto Reverse Considerations

While focusing on belts, it’s worth briefly touching upon other related mechanisms in cassette decks:

Auto Stop: Most cassette decks have an auto stop mechanism that automatically halts playback when the tape reaches the end. This prevents unnecessary wear and tear. As illustrated below, this can be achieved mechanically or electronically.

Alt text: Close-up of a cassette deck auto-stop mechanism showing the belt driving a sensor wheel connected to the tape counter.

Mechanical Auto Stop: This system uses a physical lever that senses tape tension. At the end of the tape, increased tension trips the lever, stopping the mechanism.

Electronic Auto Stop: Electronic systems, often tied to the tape counter as shown, use a hall effect or optical sensor. A belt drives a sensor wheel. As long as the tape moves, the wheel turns, and the sensor detects pulses, indicating normal operation. When the tape ends, the wheel stops, pulses cease, and the auto stop is triggered. The belt for the counter and auto stop sensor is less critical for speed accuracy; in a pinch, even a rubber band can temporarily work.

Auto Reverse: Auto reverse allows playback of both sides of a cassette without manual flipping. Most auto-reverse car cassette decks achieve this by reversing the tape direction and switching the audio tracks electronically. Some rarer mechanisms actually physically flipped the cassette.

Conclusion

Fixing a cassette deck in your car, especially belt-related issues, is a rewarding endeavor for any car or audio enthusiast. By understanding the function of belts, diagnosing common problems, and following a methodical approach to replacement, you can bring your vintage car audio back to life and enjoy the unique charm of cassette tapes on the road once again. Remember to take your time, be patient, and don’t hesitate to consult online resources and communities for further guidance if needed. With a little effort, you can keep the analog spirit alive in your car for years to come.